Copper alloy die-casting die steel and manufacturing method thereof

A die-casting mold and copper alloy technology, which is applied in the field of copper alloy die-casting mold steel and its preparation, can solve the problems of high cost and little improvement in service life, and achieve the effects of improving strength and toughness, avoiding internal stress, and decreasing thermal strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

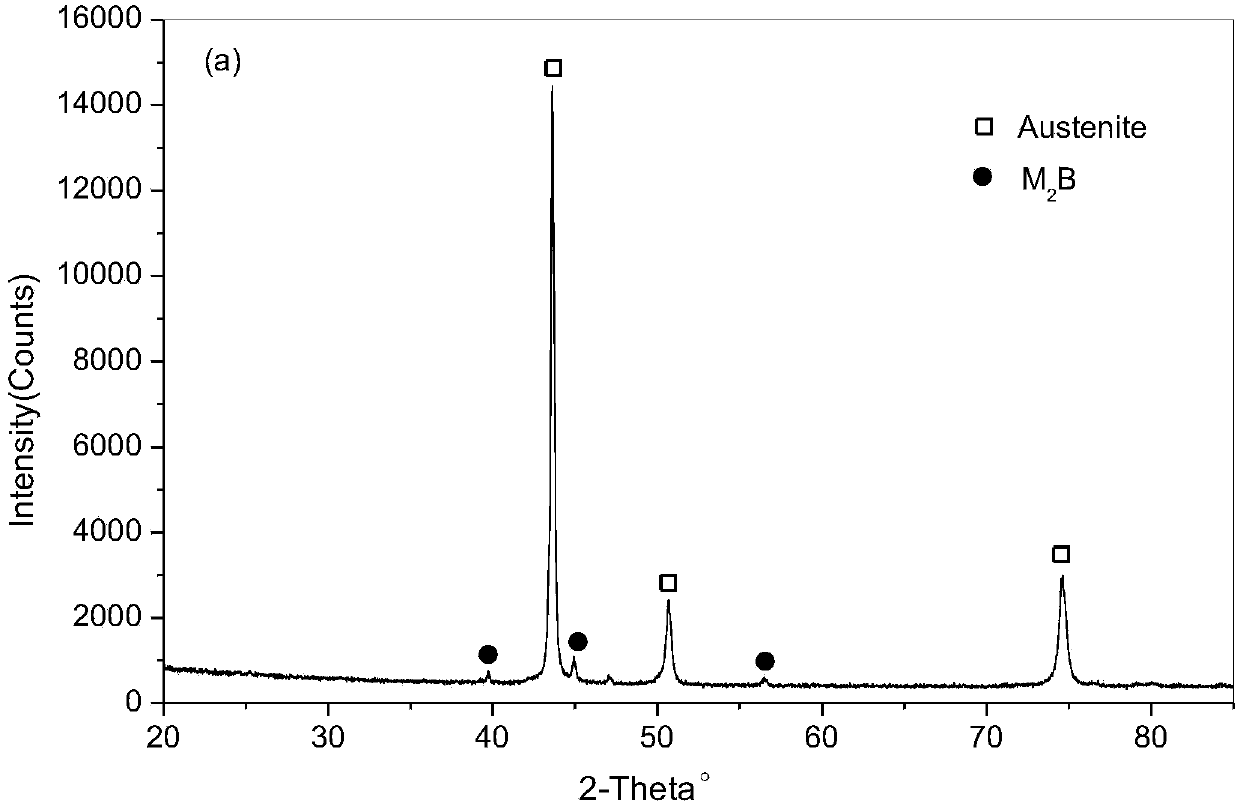

[0042] A copper alloy die-casting die steel, its chemical composition and weight percent are 0.45wt%C, 0.11wt%Si, 13.7wt%Mn, 10.8wt%Cr, 3.36wt%Ni, 1.09wt%Cu, 0.12wt%B, 0.009wt% P, 0.013wt% S, and the rest is Fe. The specific preparation steps are as follows: weighing and measuring the low-carbon steel, ferrosilicon, ferrochrome, pure nickel and pure copper after surface derusting and oil staining, putting them into a vacuum induction furnace for molten steel melting. After the furnace material is melted, immediately add graphite particles with a carbon content of 0.15wt% for refining. During the refining period, the melting temperature is controlled at 1650°C, the vacuum degree is controlled at 5Pa, and the holding time is 60min; after the refining period, use graphite particle recarburizer Adjust the carbon content; add ferroboron, and then increase the power to stir the molten steel for 1min; add ferromanganese for 5min and then leave the furnace; rush into argon before leav...

Embodiment 2

[0045] A copper alloy die-casting die steel, its chemical composition and weight percent are 0.60wt%C, 1.15wt%Si, 9.71wt%Mn, 12.4wt%Cr, 5.56wt%Ni, 0.51wt%Cu, 0.22wt%B, 0.012wt% P, 0.013wt% S, and the rest is Fe. The specific preparation steps are as follows: weighing and measuring the low-carbon steel, ferrosilicon, ferrochrome, pure nickel and pure copper after surface derusting and oil staining, putting them into a vacuum induction furnace for molten steel melting. After the charge is melted, immediately add 0.05wt% graphite particles for refining. During the refining period, the melting temperature is controlled at 1600°C, the vacuum degree is controlled at 10Pa, and the holding time is 30 minutes; after the refining period, use graphite particle recarburizer to adjust the carbon content ; Add ferroboron, then increase the power to stir the molten steel for 2 minutes; add ferromanganese for 3 minutes and then take it out of the furnace; rush into argon gas before leaving th...

Embodiment 3

[0048] A copper alloy die-casting die steel, its chemical composition and weight percent are 0.29wt%C, 0.11wt%Si, 6.71wt%Mn, 8.86wt%Cr, 8.06wt%Ni, 0.49wt%Cu, 0.75wt%B, 0.012wt% P, 0.010wt% S, and the rest is Fe. The specific preparation steps are as follows: weighing and measuring the low-carbon steel, ferrosilicon, ferrochrome, pure nickel and pure copper after surface derusting and oil staining, putting them into a vacuum induction furnace for molten steel melting. After the furnace material is melted, immediately add 0.1wt% graphite particles for refining. During the refining period, the melting temperature is controlled at 1700°C, the vacuum degree is controlled at 0.5Pa, and the holding time is 40min; content; add ferroboron, then increase the power to stir the molten steel for 2 minutes; add ferromanganese for 3 minutes and then release it; rush into argon before leaving the furnace, the pressure of argon is 10000Pa, the casting temperature is controlled at 1600 ° C, dir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com