Lifting device and long steel rail transport vehicle set

A hoisting device and long steel rail technology, applied in the field of machinery, can solve the problems of difficulty in controlling the magnitude of the force, unfavorable safe operation, increasing uncertain factors, etc., and achieve the trend of not easy to shake and straighten, accurate hydraulic power control, and enhanced safety. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

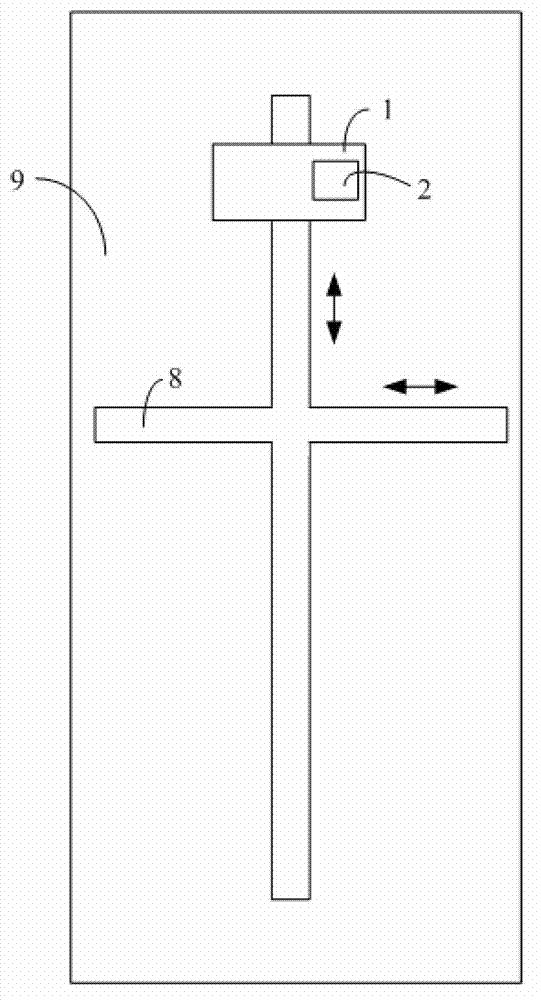

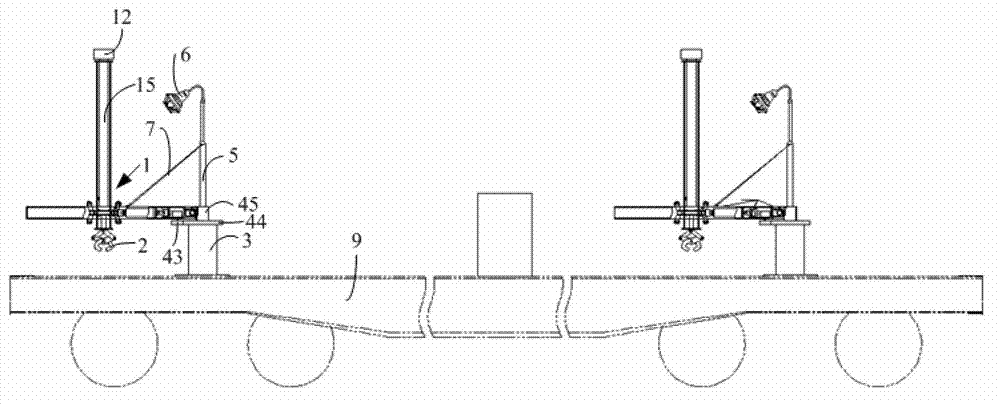

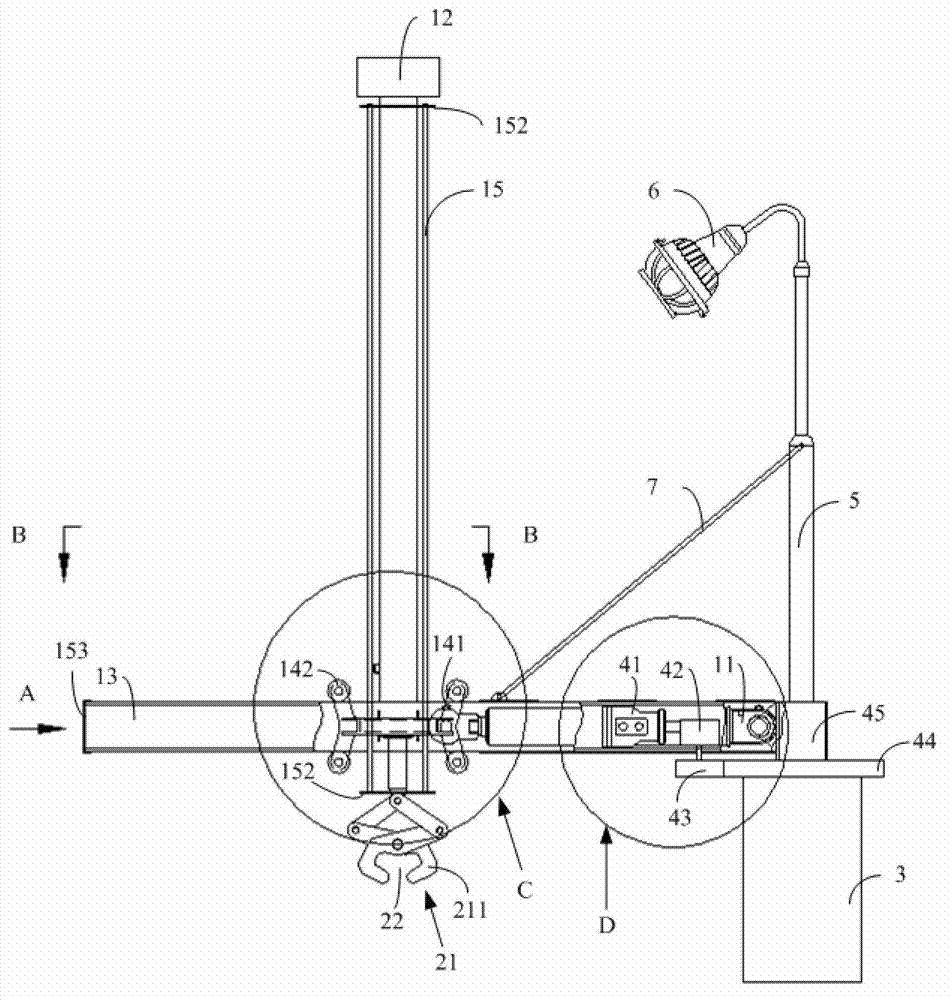

[0030] figure 1 It is a schematic structural diagram of the lifting device provided by Embodiment 1 of the present invention.

[0031] see figure 1 , Embodiment 1 of the present invention provides a lifting device, which includes a hydraulic power component 1 and a clamping component 2; The long rail transport vehicle group 9 moves horizontally and vertically; the clamping part 2 is connected with the hydraulic power part 1, and the hydraulic power part 1 drives the movement of the clamping part 2, and the clamping part 2 is used for clamping holding rails.

[0032] In this paper, the length direction of the long rail transport car group 9 is taken as the longitudinal direction, the width direction as the transverse direction, and the height direction as the vertical direction. The hydraulic power unit 1 adopts hydraulic cylinders and hydraulic pumps, for example, and the number of hydraulic cylinders can be one or more. The clamping part 2 is, for example, a manipulator, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com