Construction method of suspended steel gallery

A construction method and hanging technology, which is applied in the field of hoisting construction of hanging steel corridors, can solve problems such as the internal stress of the hanging structure deformation, the stress state does not match the design, and the inability to complete the bearing corridors, etc., to avoid The effect of reinforcement, shortening the construction period, and accelerating construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045]The present invention is further described below in conjunction with accompanying drawing and embodiment:

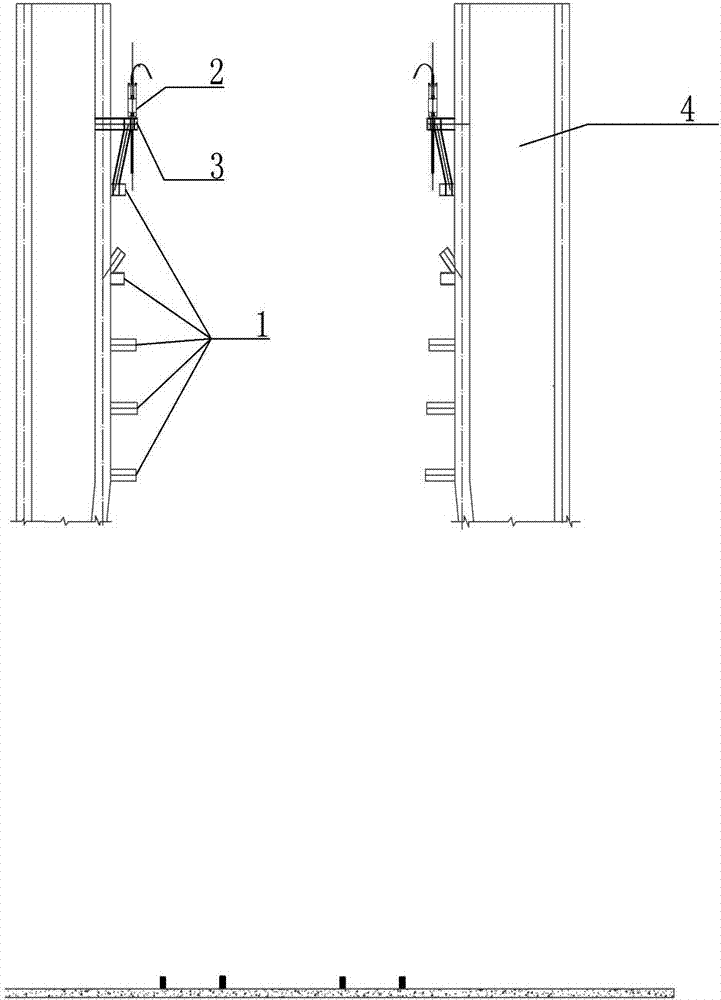

[0046] The present invention is a hoisting construction method for a hanging steel corridor. The hanging steel corridor is connected between the main structures 4 that have been built. Step 1 is to install a pre-installed rod 1 at the design elevation of the steel corridor , set lifting platforms 3 on the pre-installed rods 1, set at least four sets of lifting platforms 3, and install a hydraulic lifter 2 on each set of lifting platforms 3 (such as figure 1 shown); install hydraulic synchronous lifting system equipment, including hydraulic pump source system, hydraulic lifter 2, sensors, etc.;

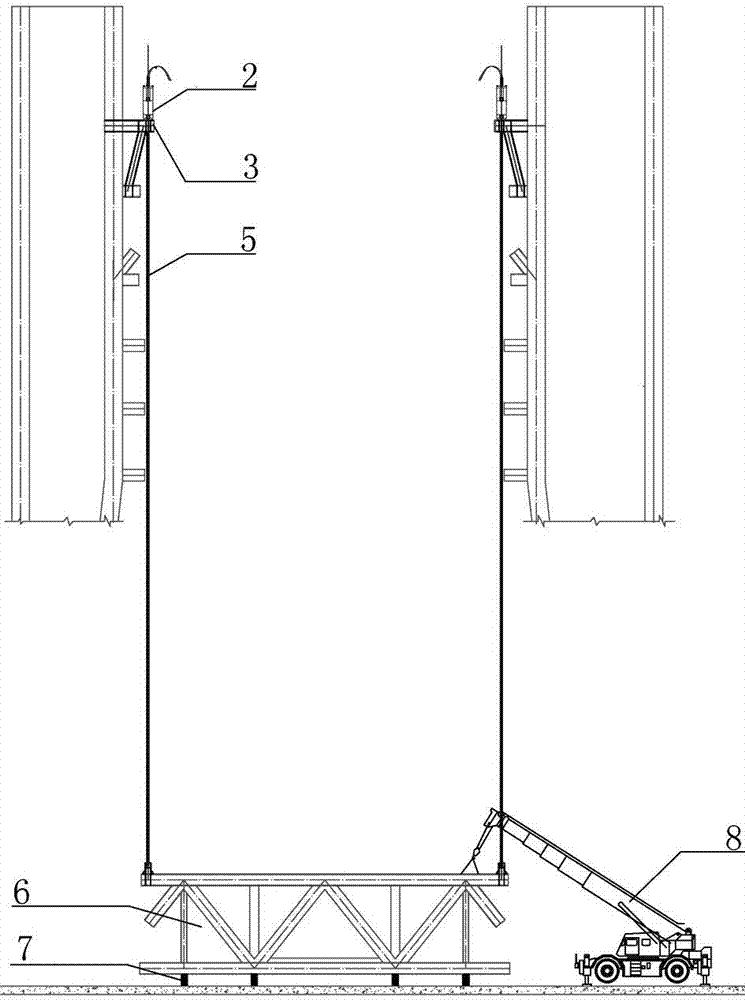

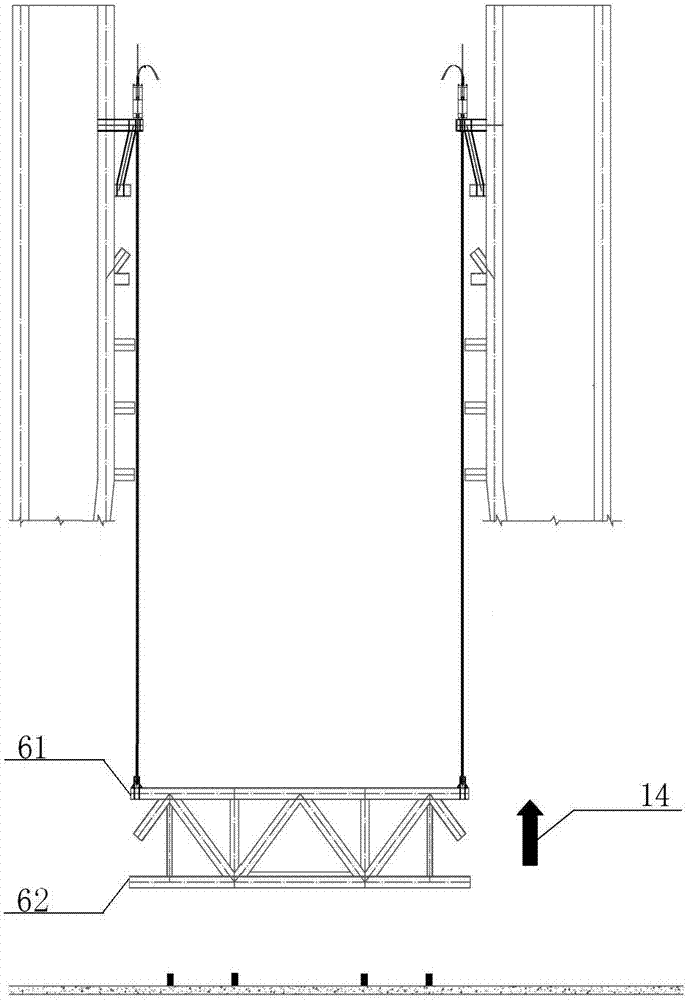

[0047] Step 2, assemble under the projection of the predetermined installation position of the suspended steel corridor, use the truck crane 8 to assemble the upper truss structure 6 of the suspended steel corridor at the elevation of ±0.000 of the basement roof, and debug ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com