Cross member

A beam, horizontal technology, applied in the superstructure, superstructure sub-assembly, transportation and packaging, etc., can solve problems such as labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

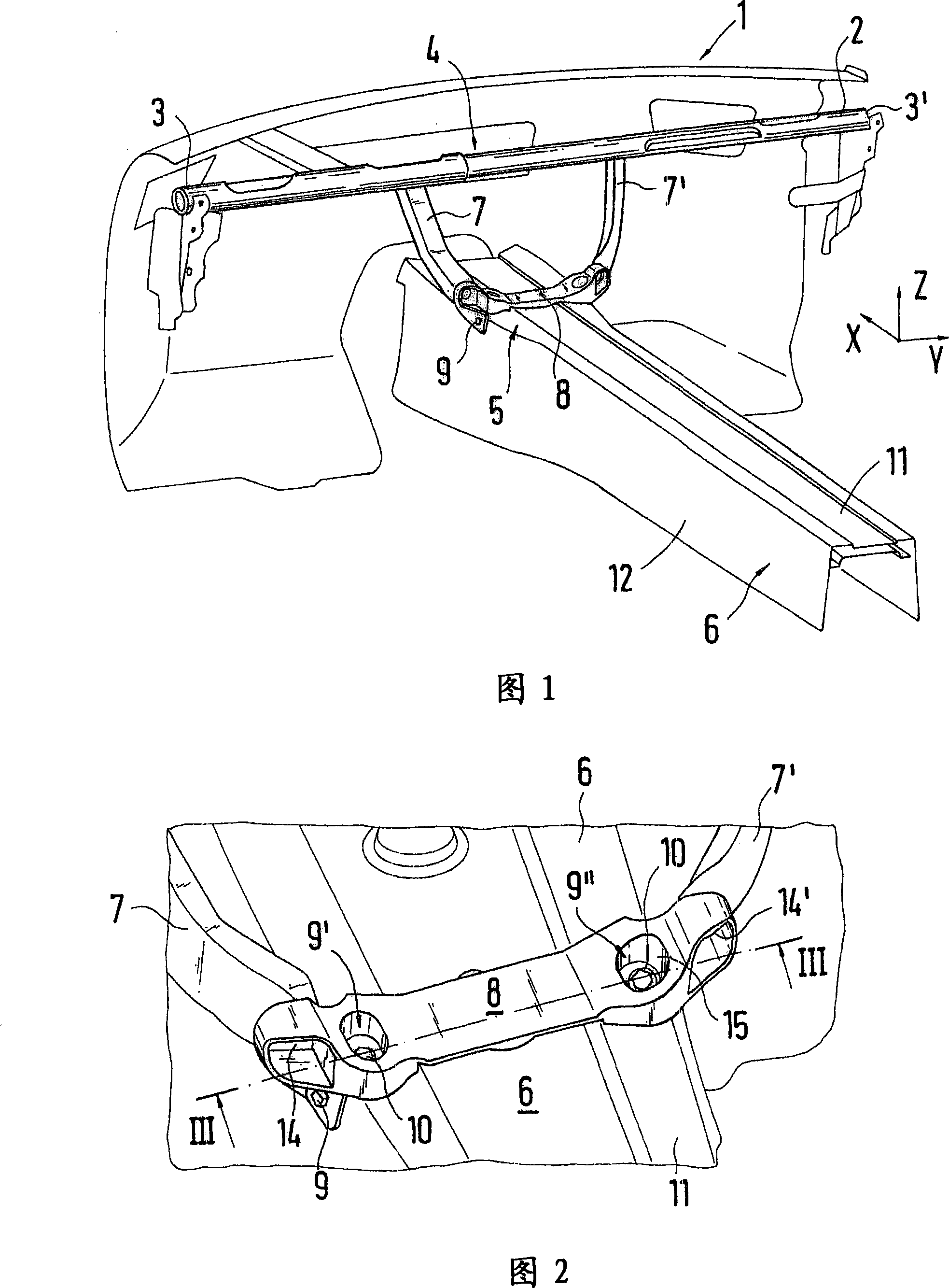

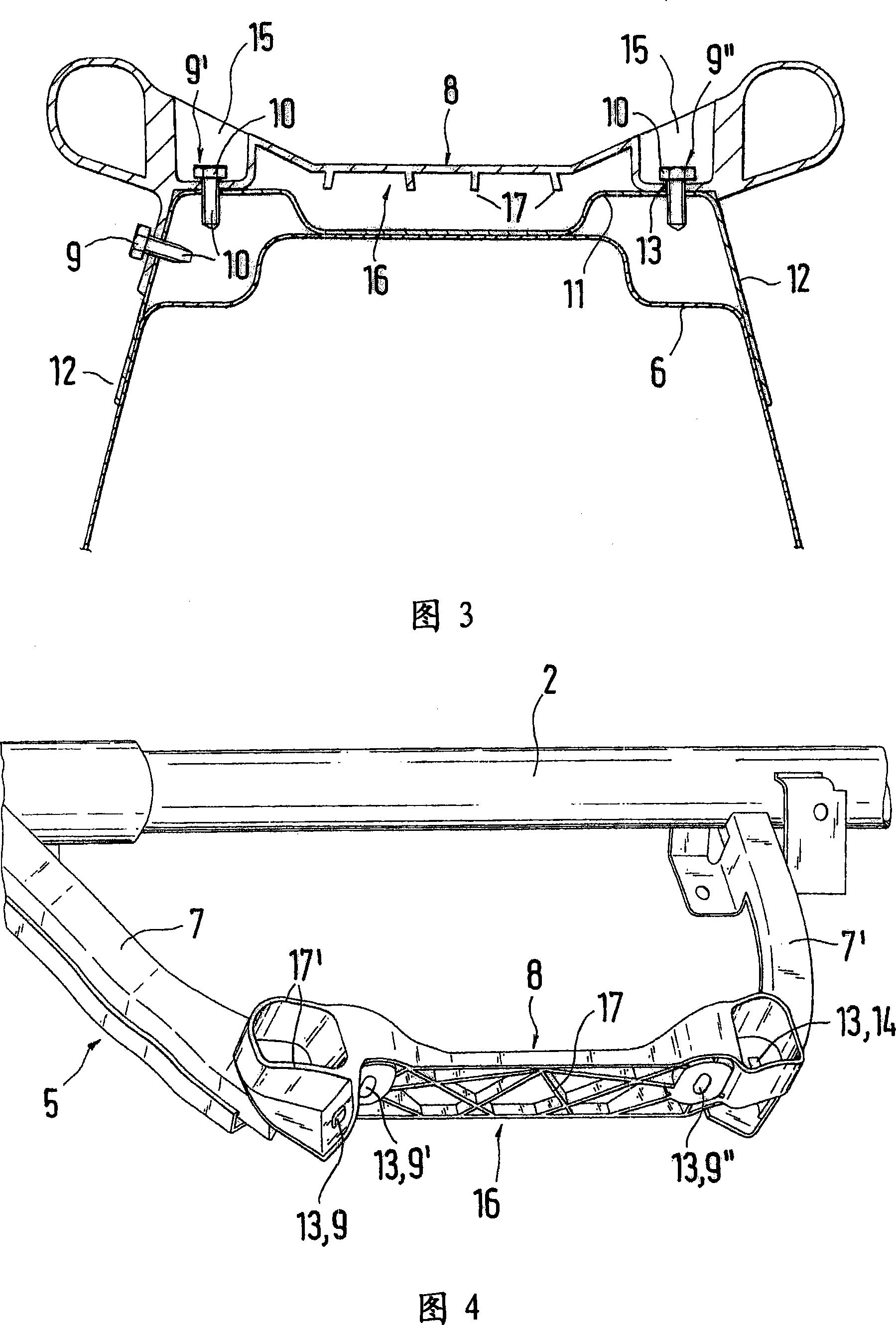

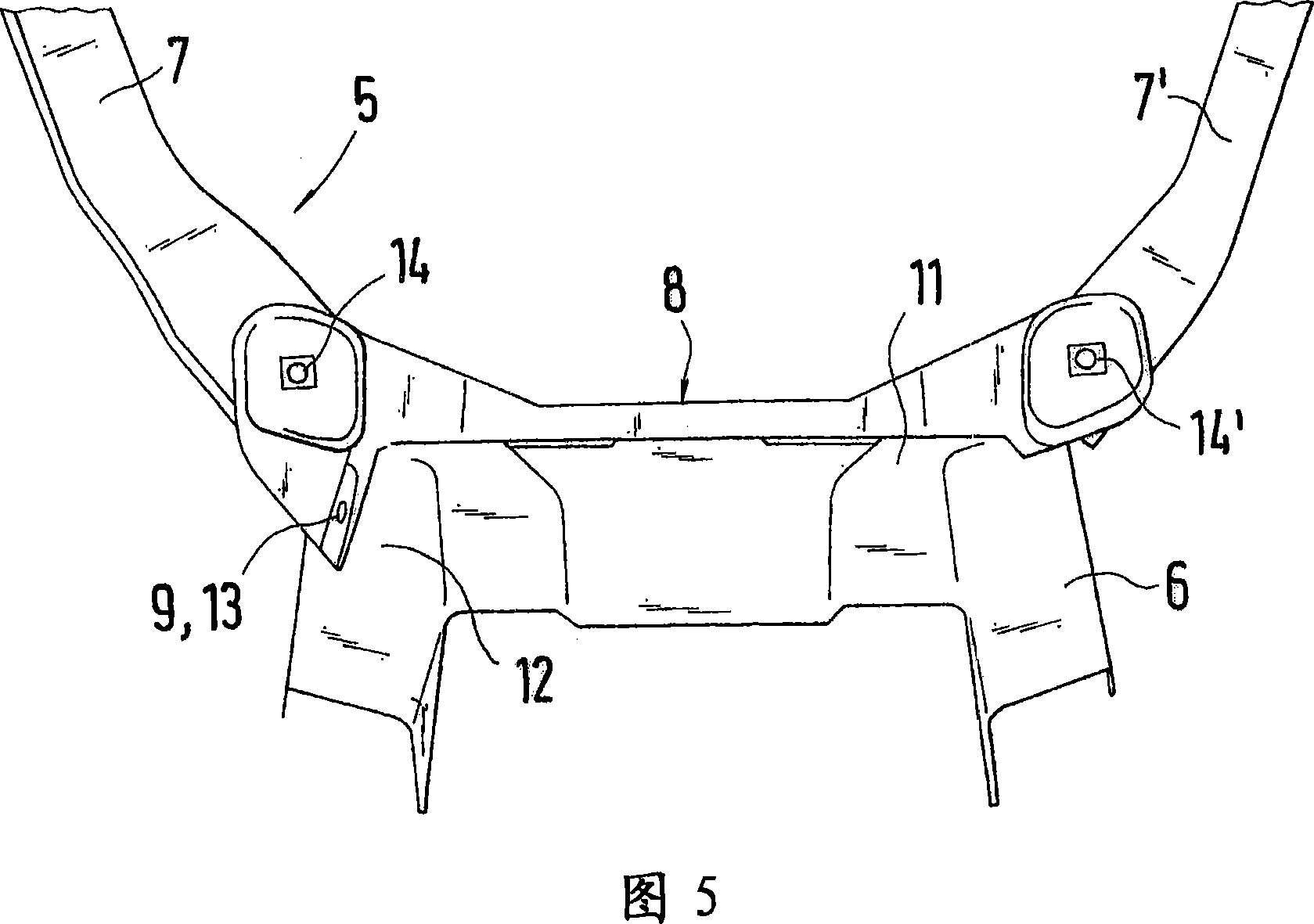

[0017] FIG. 1 shows a front structure 1 of a motor vehicle, not shown in other parts, which forms the front end of the passenger compartment. The front vehicle structure 1 is part of the vehicle body (not shown), on which a cross member 2 , here the driver's cab cross member 2 , is arranged, which usually serves as a support for an instrument panel, also not shown . The longitudinal ends 3 and 3 of the cross member 2 are firmly connected to the A-pillar of the vehicle, not shown, so that the cross member 2 increases the stiffness of the vehicle in the transverse direction. The driver's cross member 2 is supported in its central part 4 by means of a bracket 5 on the longitudinal central tunnel 6 of the motor vehicle, so that unintentional deformation of the cross member 2 , for example caused by the load of the instrument panel, can be avoided. In this case, the longitudinal central channel 6 generally serves as a channel for a not shown vehicle drive shaft, which extends, for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com