Rubber power for building

A technology for construction and rubber powder, applied in the field of rubber powder, which can solve the problems of being unpopular with users, not being able to be used alone, and poor engineering quality, and achieving the effect of low price, convenient transportation and good quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The rubber powder for construction of the present invention comprises the following components: 12.2.kg of prechemical starch, 22.25kg of hydroxypropyl methylcellulose, 30.5kg of PVA, 35kg of oxidized starch, 8kg of redispersible latex powder, 4kg of borax, calcium propionate 0.8kg, edible alum 10kg.

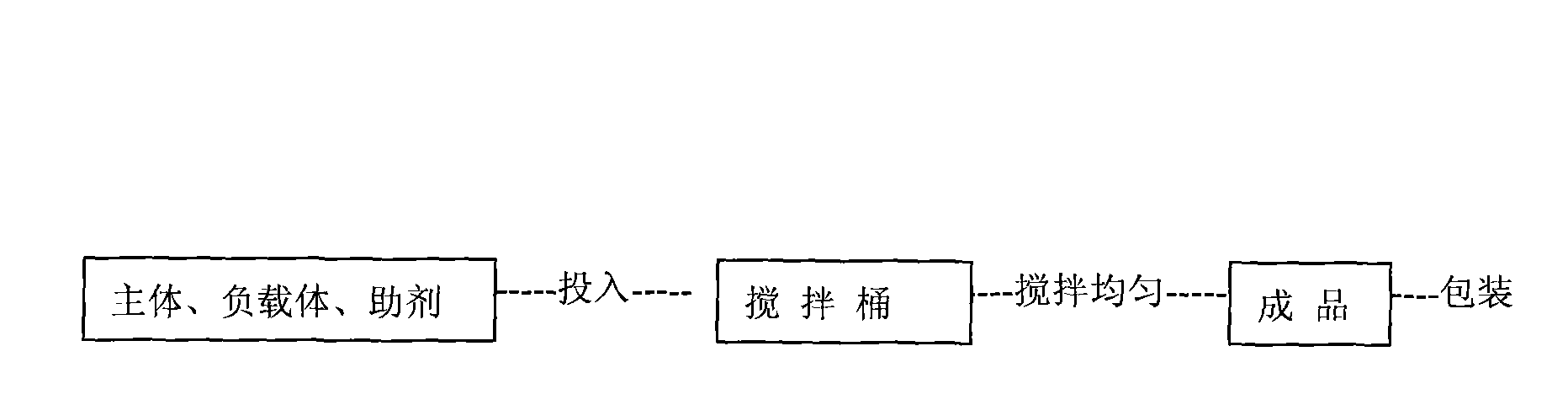

[0046] The preparation process is as follows: each component is weighed according to the above weight, put into a mixing bucket in turn, and then stirred and mixed evenly to obtain the product.

Embodiment 2

[0048] The rubber powder for construction of the present invention comprises the following components: hydroxyalkyl starch ether 12.2.kg, hydroxypropyl cellulose 22.25kg, PVA 30.5kg, oxidized starch 35kg, redispersible latex powder 8kg, borax 4kg, propionic acid Sodium 0.8kg, edible alum 10kg.

[0049] The preparation process is as follows: each component is weighed according to the above weight, put into a mixing bucket in turn, and then stirred and mixed evenly to obtain the product.

Embodiment 3

[0051] The rubber powder for construction of the present invention comprises the following components: 12.2.kg of preformed starch, 12.25kg of hydroxypropyl methylcellulose, 10kg of hydroxypropylcellulose, 30.5kg of PVA, 35kg of oxidized starch, and 8kg of redispersible latex powder , borax 4kg, calcium propionate 0.5kg, sodium propionate 0.3kg, edible alum 10kg.

[0052] The preparation process is as follows: each component is weighed according to the above weight, put into a mixing bucket in turn, and then stirred and mixed evenly to obtain the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com