Environment-friendly bamboo fiber material and preparation method thereof

An environmentally friendly material, bamboo fiber technology, applied in the field of polymer materials, can solve the problems of mechanical properties, water resistance, durability, low interface bond strength, poor compatibility, etc., to improve heat resistance and mechanical properties. , the effect of mechanical adhesion enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

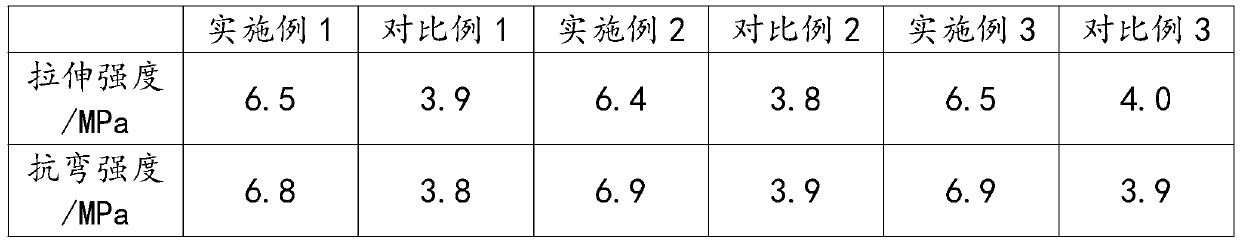

Examples

preparation example Construction

[0051] The preparation method of described bamboo fiber environmental protection material, comprises the steps:

[0052] Step 1. Weigh each raw material according to the parts by weight, mix them uniformly, and place them sealed at room temperature for 12 hours;

[0053] Step 2, mixing with an open double-roller mixer, the mixing temperature is 160°C, and the mixing time is 10-15min;

[0054] Step 3. After cooling, crush it into granules with a powerful crusher, pour it into a hot-pressed mold, and make the surface even and flat. The stacking height exceeds the mold by 0.8-1.2mm, and a layer is attached to the surface and bottom Tin foil to prevent the material from sticking to the hot-pressed iron plate;

[0055] Step 4: Slowly put the mold into a hot press machine for hot pressing. The hot pressing time is 20 minutes, the hot pressing temperature is 160° C., and the pressure is 10 MPa to prepare the bamboo fiber environmental protection material.

Embodiment 1

[0057] A bamboo fiber environmental protection material is made of the following raw materials in parts by weight: 30 parts of polylactic acid, 10 parts of polybutylene succinate, 20 parts of modified bamboo fiber, 10 parts of plasticizer, and 2 parts of antibacterial agent;

[0058] The plasticizer is a compound of glycerin, citric acid ester, and ethylene glycol, and glycerin, citric acid ester, and ethylene glycol are compounded according to a mass ratio of 10:3:5;

[0059] The preparation method of described bamboo fiber environmental protection material, comprises the steps:

[0060] Step 1. Weigh each raw material according to the parts by weight, mix them uniformly, and place them sealed at room temperature for 12 hours;

[0061] Step 2, mixing with an open double-roller mixer, the mixing temperature is 160 ° C, and the mixing time is 10 minutes;

[0062] Step 3. After cooling, crush it into granules with a powerful crusher, pour it into a hot-pressed mold, and make th...

Embodiment 2

[0065] A bamboo fiber environmental protection material is made of the following raw materials in parts by weight: 35 parts of polylactic acid, 14 parts of polybutylene succinate, 25 parts of modified bamboo fiber, 13 parts of plasticizer, and 2.5 parts of antibacterial agent;

[0066] The plasticizer is a compound of glycerin, citrate, and ethylene glycol, and glycerin, citrate, and ethylene glycol are compounded according to a mass ratio of 10:3.5:6.5;

[0067] The preparation method of described bamboo fiber environmental protection material, comprises the steps:

[0068] Step 1. Weigh each raw material according to the parts by weight, mix them uniformly, and place them sealed at room temperature for 12 hours;

[0069] Step 2, mixing with an open double-roller mixer, the mixing temperature is 160 ° C, and the mixing time is 13 minutes;

[0070] Step 3. After cooling, crush it into granules with a powerful crusher, pour it into a hot-pressed mold, and make the surface even...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com