Novel pile loop fabric and method for producing same

A technology of terry and fabrics, applied in fabrics, textiles, textiles and papermaking, etc., can solve the problems of easy hardening, high rigidity of linen, and difficult washing, etc., and achieve high water absorption, easy wet and quick dry, soft and easy wet Quick-drying, good moisture absorption and air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

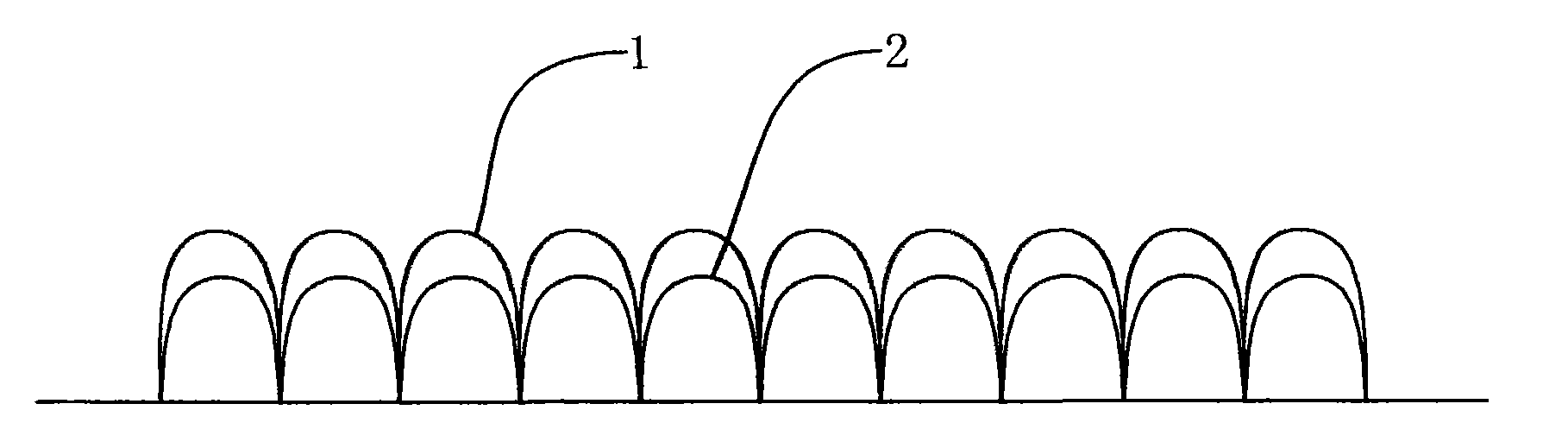

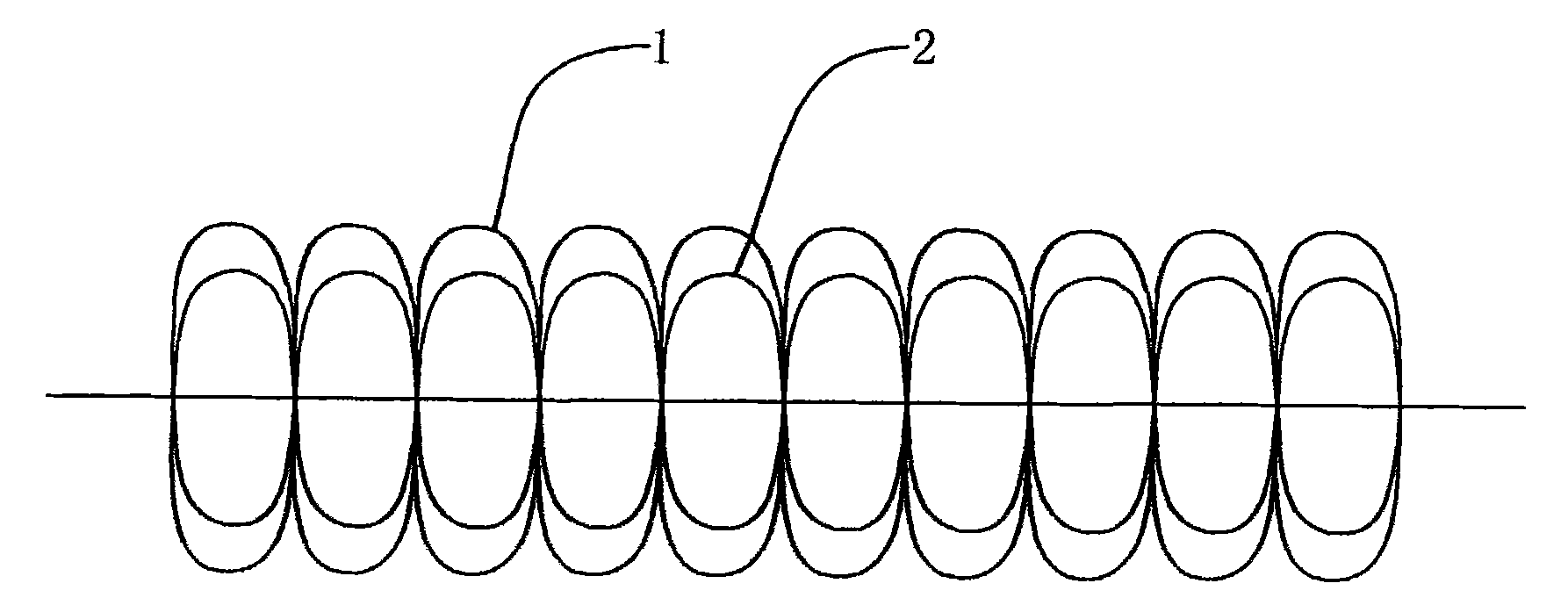

[0024] like figure 1 , 2 , 3, 4 or 5, the novel terry fabric, the fabric is a single-sided or double-sided terry fabric, and the terry includes an outer layer terry 1 and an inner layer terry 2.

[0025] The outer layer terry 1 is a natural fiber terry, and the inner layer terry 2 is a superfine fiber terry.

[0026] The method of producing new-type terry fabrics by knitting and weaving technology: the production process is bobbin loading, warping, pan head loading, yarn separation, bar loading, weaving, gray cloth, unwinding, fiber opening, cleaning, dyeing, shaping, punching Volume, storage.

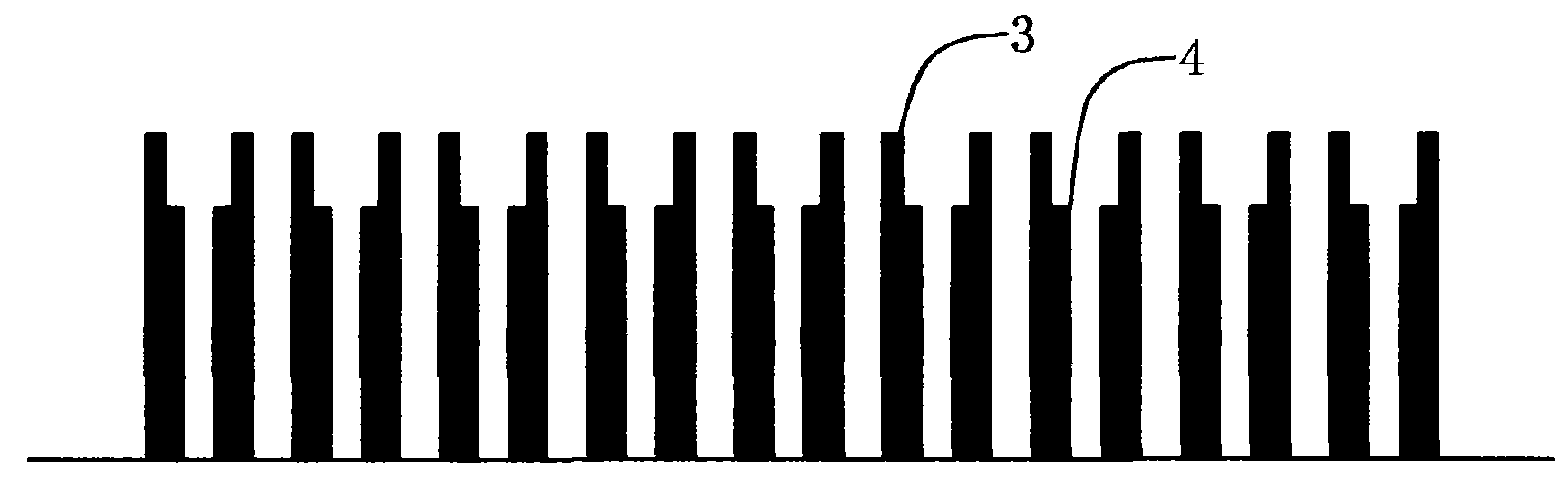

[0027] The terry fabric is that the first bar and the third bar use 150D / 72F DTY polyester nylon composite low elastic yarn and 32 s Cotton yarn is also used as the raw material for the loops. The second bar uses 150D / 72F DTY polyester-nylon composite low elastic yarn, and the fourth bar uses 200D / 96F FDY polyester textured yarn. The gray cloth is post-processed to obtain the novel...

Embodiment 2

[0045] like figure 1 , 2 , 3, 4, or 5, a novel terry fabric, the fabric is a single-sided or double-sided terry fabric, and the terry includes an outer layer terry 1 and an inner layer terry 2.

[0046] The outer layer terry 1 is a natural fiber terry, and the inner layer terry 2 is a superfine fiber terry.

[0047] The method for producing the new-type terry fabric by the weaving process: the production process is: winding, warping, weaving, dyeing, shaping, and storage.

[0048] The wool warp is 300D DTY polyester nylon composite low elastic yarn and 20 s Cotton yarns are arranged alternately; the ground warp yarn is 300D DTY polyester nylon composite low elastic yarn; the weft yarn is 300D FDY polyester textured yarn, which is warped and woven into a gray cloth, and then the gray cloth is post-treated to obtain the new loop fabric.

[0049] The arrangement ratio of the wool warp and the ground warp is 1:1 or 2:1 or 1:2 or 2:2; the arrangement ratio of the natural fiber a...

Embodiment 3

[0073] like figure 1 , 2 , 3, 4 or 5, the method for producing the novel terry fabric, the terry fabric adopts natural fiber as the raw material of the outer layer terry 1, and the superfine fiber is the raw material of the inner layer terry 2 , chemical fiber filaments or natural fibers are used as the raw material of the bottom structure, and the gray cloth is woven into a gray cloth by a knitting process, and then the gray cloth is post-treated to obtain the new loop fabric.

[0074] In the knitting process, the loops are arranged alternately with superfine fiber filaments and natural fibers, and the bottom tissue is made of chemical fiber filaments or natural fibers.

[0075] The gray fabric post-processing includes unwinding, fiber opening, cleaning, dyeing and setting.

[0076] The gray cloth is subjected to single-side cut pile treatment, and after post-processing, a single-side plush fabric or a plush loop fabric with loops and plush separated on two sides is obtaine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com