Method for preparing fibers with performance of sheep wool and imitated wool fabric

A technology of sheep wool and fiber, which is applied in the field of preparation of imitation sheep wool fiber, can solve the problems of not being able to reflect the plush effect of animal fur, not being able to reflect the warm-keeping characteristics of animal fur, and not being able to realize the curling effect of wool, so as to achieve a remarkable warmth-keeping effect and improve Warmth performance, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

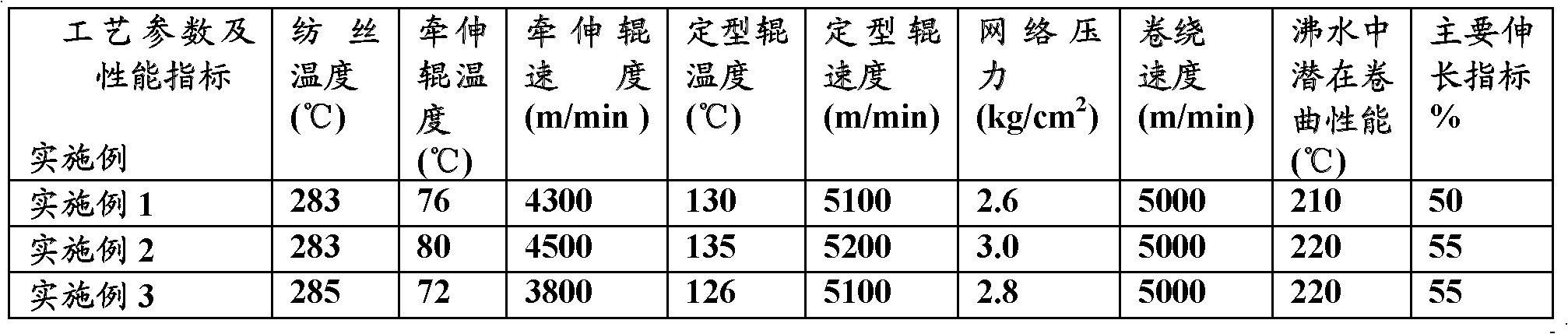

Embodiment 1

[0028] This embodiment provides a method for preparing fibers with sheep wool properties, comprising the following steps:

[0029] (1), using TIO 2 The full-dull PET chip with a content of about 3.0wt% and an intrinsic viscosity of 0.665 is used as the first raw material. It is pre-crystallized at 145°C to 150°C, and then dried at 165°C to 170°C for 6 hours. In mixing devices with antistatic devices;

[0030] (2) Using water-soluble PET chips as the second raw material, first crystallize at 126°C, then dry at 130°C to 135°C for 8 hours, and enter the mixing device. The amount of the water-soluble PET chips is the total fiber 2.5% by weight;

[0031] (3), with the masterbatch of the far-infrared material that contains bamboo charcoal as the 3rd raw material, after masterbatch is pre-dried to moisture content below 30ppm, enter in described mixing device, the consumption of the 3rd raw material is the fiber gross weight 2%;

[0032] (4), with the calcium titanate masterbatch...

Embodiment 2

[0035] The present embodiment provides a kind of preparation method of the fiber with sheep wool property, it comprises the following steps:

[0036] (1), using TIO 2 The full-dull PET chip with a content of about 3.4wt% and an intrinsic viscosity of 0.663 is used as the first raw material. It is pre-crystallized at 145°C to 150°C, and then dried at 165°C to 170°C for 6 hours. In mixing devices with antistatic devices;

[0037] (2) Using water-soluble PET slices as the second raw material, first crystallize at 126°C, then dry at 130°C to 135°C for 8 hours, and enter the mixing device. The amount of the water-soluble PET slices is the total amount of fibers 2.5% by weight;

[0038] (3), take the masterbatch of tourmaline as the third raw material, after the masterbatch is pre-dried to a water content below 30ppm, enter in the mixing device, the consumption of the third raw material is 3.5% of the total weight of the fiber;

Embodiment 3

[0042] The present embodiment provides a kind of preparation method of the fiber with sheep wool property, it comprises the following steps:

[0043] (1), using TIO 2 The full-dull PET chip with a content of about 2.9wt% and an intrinsic viscosity of 0.663 is used as the first raw material, which is pre-crystallized at 145°C to 150°C, then dried at 165°C to 170°C for 6 hours, and controlled by a computer. In mixing devices with antistatic devices;

[0044] (2) Using water-soluble PET chips as the second raw material, first crystallize at 126°C, then dry at 130°C to 135°C for 8 hours, and enter the mixing device. The amount of the water-soluble PET chips is the total fiber 2.5% by weight;

[0045] (3), with the masterbatch containing far-infrared material (ceramic) as the third raw material, after the masterbatch is pre-dried to a moisture content below 30ppm, enter the mixing device, the consumption of the third raw material is 1 / 2 of the total weight of the fiber 2%;

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Moisture content | aaaaa | aaaaa |

| Moisture content | aaaaa | aaaaa |

| Moisture content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com