Treatment process for improving moisture absorption performance of silk fibers

A technology of hygroscopic performance and processing technology, applied in the field of silk processing, can solve the problems of reduced mechanical properties and poor hygroscopicity of silk fibers, and achieve the effects of reducing crystallinity, improving hygroscopic performance and improving hygroscopic performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

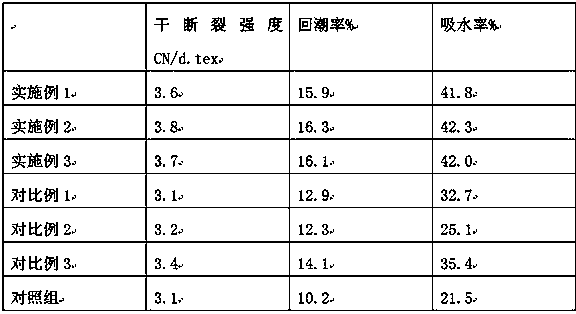

Examples

Embodiment 1

[0019] A treatment process for improving the hygroscopicity of silk fibers, comprising the following steps:

[0020] (1) Dissolve xylan in a solvent to prepare a xylan solution with a mass fraction of 8.5%, then add maleate with a mass fraction of 5.5% xylan, heat to 180°C, and heat at 500r / min Stir at a rotating speed for 2 hours to obtain a mixed solution;

[0021] (2) Add 3.5% triethylamine by mass to the mixed solution obtained above, react at 120°C for 2 hours, then precipitate the reaction product in ethanol, filter, wash, vacuum dry, pulverize and grind , through a 300-mesh sieve to obtain a modifier;

[0022] (3) Dissolving the modifier obtained above in an ethanol solution at a ratio of 40g: 200mL to obtain a modified solution;

[0023] (4) Add the silk to the modified solution at a ratio of 80g: 300mL, then add the modified solution to the reaction kettle, pass inert gas into the reaction kettle, remove the air, vacuumize, and then soak for 40min. Then filter the ...

Embodiment 2

[0032] A treatment process for improving the hygroscopicity of silk fibers, comprising the following steps:

[0033] (1) Dissolve xylan in a solvent to prepare a xylan solution with a mass fraction of 10%, then add maleate with 5.5% xylan mass, heat to 180°C, and heat at 500r / min Stir at a rotating speed for 2 hours to obtain a mixed solution;

[0034] (2) Add 5% of its mass of triethylamine to the mixed solution obtained above, react at 120°C for 2 hours, then precipitate the reaction product in ethanol, filter, wash, vacuum dry, pulverize and grind , through a 300-mesh sieve to obtain a modifier;

[0035] (3) Dissolving the modifier obtained above in an ethanol solution at a ratio of 45g: 200mL to obtain a modified solution;

[0036] (4) Add the silk to the modified solution at a ratio of 85g: 300mL, then add the modified solution to the reaction kettle, pass inert gas into the reaction kettle, remove the air, vacuumize, and then soak for 45min. Then filter the silk, use ...

Embodiment 3

[0045] A treatment process for improving the hygroscopicity of silk fibers, comprising the following steps:

[0046] (1) Dissolve xylan in a solvent, configure a xylan solution with a mass fraction of 9%, and then add maleate with a mass fraction of 5.5% xylan, heat to 180°C, and heat at 500r / min Stir at a rotating speed for 2 hours to obtain a mixed solution;

[0047] (2) Add 4% triethylamine by mass to the mixed solution obtained above, react at 120°C for 2 hours, then precipitate the reaction product in ethanol, filter, wash, and dry in vacuum, then pulverize and grind , through a 300-mesh sieve to obtain a modifier;

[0048] (3) The modifier obtained above was dissolved in an ethanol solution at a ratio of 42g: 200mL to obtain a modified solution;

[0049] (4) Add the silk to the modified solution at a ratio of 83g: 300mL, then add the modified solution to the reaction kettle, pass inert gas into the reaction kettle, remove the air, vacuumize, and then soak for 42min. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com