Preparation method of silicon dioxide modified porous polyvinyl alcohol non-woven fabric

A technology of porous polyvinyl alcohol and silicon dioxide, which is applied in chemical instruments and methods, non-woven fabrics, textiles and papermaking, etc., can solve the problems of rare reports, achieve moderate porosity, uniform pore distribution, and moisture absorption. The effect of excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

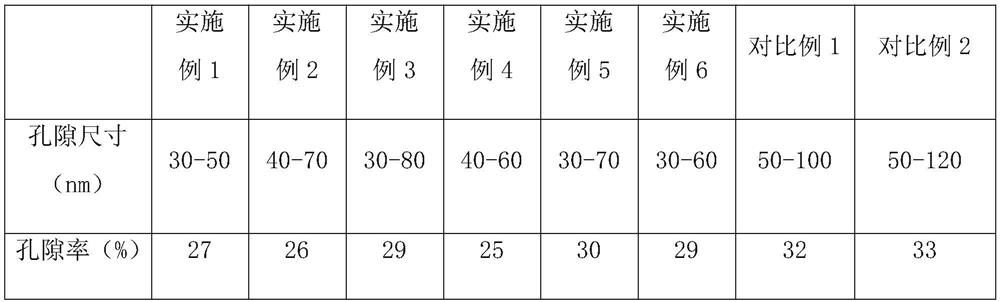

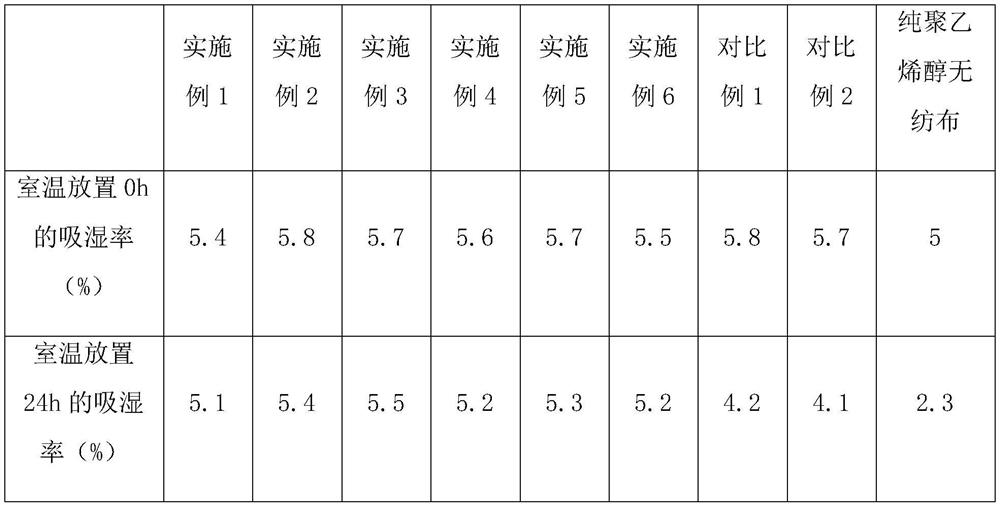

Examples

Embodiment 1

[0026] (1) Add polyvinyl alcohol powder into deionized water, heat and dissolve at 35° C. to obtain a polyvinyl alcohol solution with a content of 10 wt%.

[0027] (2) According to the ratio of the amount of the silicon precursor to the deionized water is 1:3.5, add the silicon precursor to the deionized water, mix well, add polyethylene glycol solution, continue to stir evenly, add hydrochloric acid dropwise Adjust the pH value of the system to 3, and add polyethylene glycol dropwise while stirring and reacting at a rate of 1000r / min for 1h to obtain a silica-modified polyvinyl alcohol solution. In the silica-modified polyvinyl alcohol solution, the The mass ratio of silicon, ethylene glycol and polyvinyl alcohol is 1:7:13.

[0028] (3) Add 3% of the total mass of aminated silica sol to the silica-modified polyvinyl alcohol solution, stir evenly, and place it in the electrospinning equipment at a voltage of 17kV and a receiving distance of 20cm Under the conditions of electr...

Embodiment 2

[0032] (1) Add polyvinyl alcohol powder into deionized water, heat and dissolve at 40° C. to obtain a polyvinyl alcohol solution with a content of 15 wt%.

[0033] (2) According to the ratio of the amount of the silicon precursor to the deionized water is 1:4, add the silicon precursor to the deionized water, mix well, add polyethylene glycol solution, continue to stir evenly, add hydrochloric acid dropwise Adjust the pH value of the system to 4, and add polyethylene glycol dropwise while stirring and reacting at a rate of 2000r / min for 2 hours to obtain a silica-modified polyvinyl alcohol solution. In the silica-modified polyvinyl alcohol solution, the The mass ratio of silicon, ethylene glycol and polyvinyl alcohol is 1:10:18.

[0034] (3) Add aminated silica sol accounting for 5% of the total mass to the silica-modified polyvinyl alcohol solution, stir evenly, and place it in the electrospinning equipment at a voltage of 20kV and a receiving distance of 25cm Under the cond...

Embodiment 3

[0038](1) Add polyvinyl alcohol powder into deionized water, heat and dissolve at 40° C. to obtain a polyvinyl alcohol solution with a content of 15 wt%.

[0039] (2) According to the ratio of the amount of the silicon precursor to the deionized water is 1:4, add the silicon precursor to the deionized water, mix well, add polyethylene glycol solution, continue to stir evenly, add hydrochloric acid dropwise Adjust the pH value of the system to 4, and add polyethylene glycol dropwise while stirring and reacting at a rate of 2000r / min for 2 hours to obtain a silica-modified polyvinyl alcohol solution. In the silica-modified polyvinyl alcohol solution, the The mass ratio of silicon, ethylene glycol and polyvinyl alcohol is 1:10:18.

[0040] (3) Add aminated silica sol accounting for 5% of the total mass to the silica-modified polyvinyl alcohol solution, stir evenly, and place it in the electrospinning equipment at a voltage of 20kV and a receiving distance of 25cm Under the condi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com