Fuel pump with outlet valve in piston and fuel path of flushing actuator

A fuel path and fuel pump technology, applied to fuel injection devices with stress-reducing measures, fuel injection devices with piezoelectric elements or magnetostrictive elements, fuel injection pumps, etc., can solve fuel pump efficiency deterioration, delivery It can reduce the flow resistance, uniform cooling, compact structure and other problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

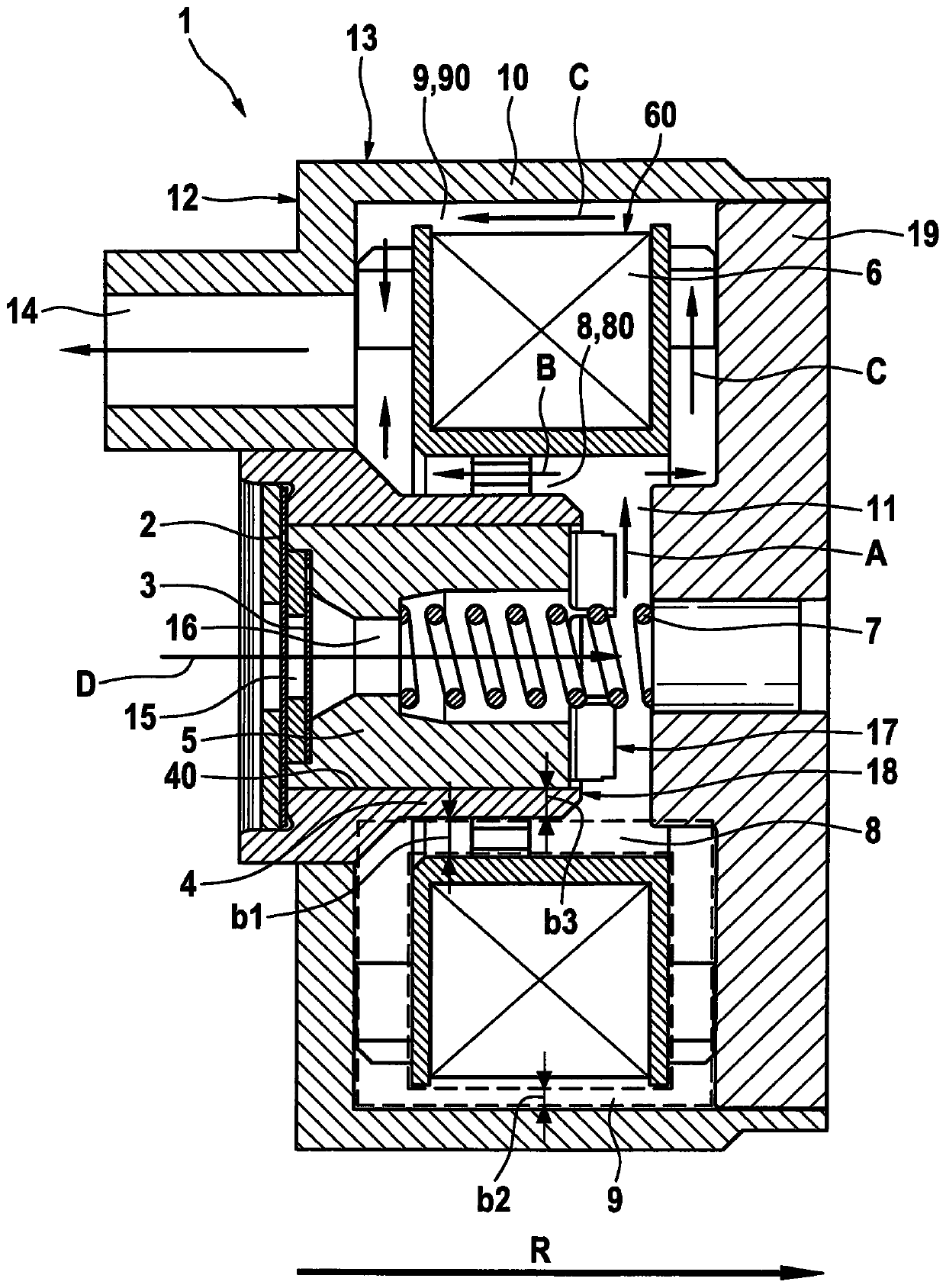

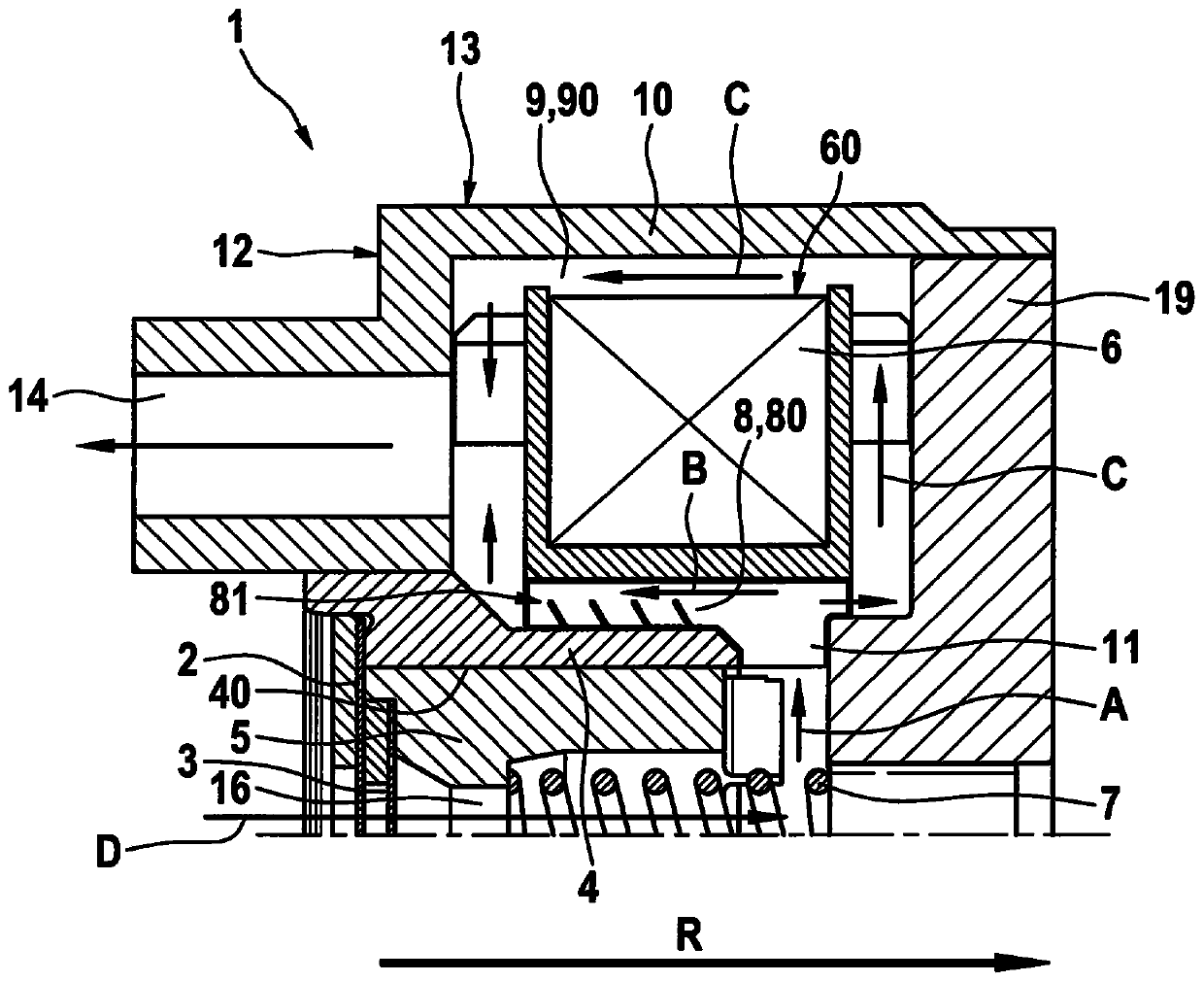

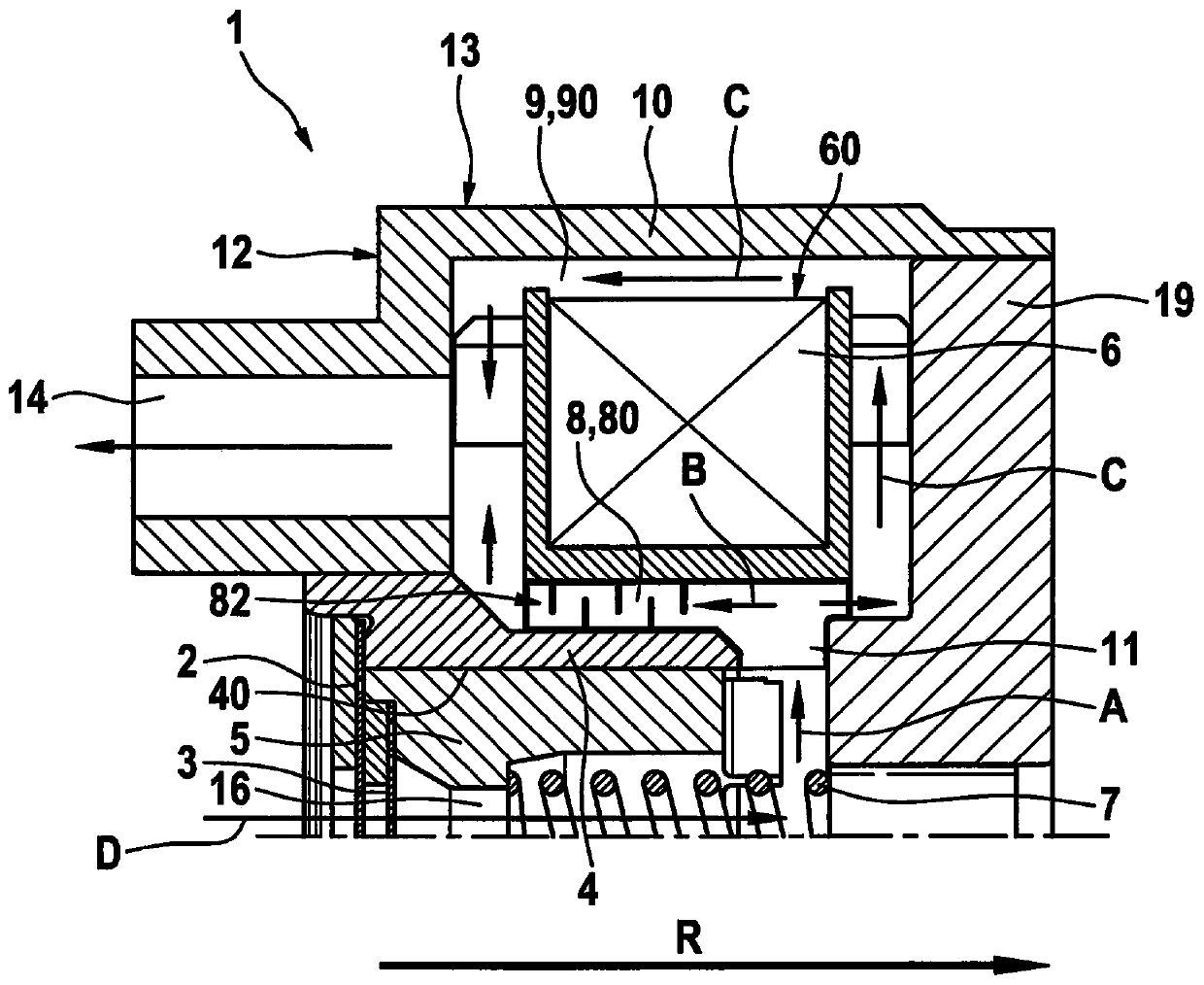

[0029] Refer below figure 1 A fuel pump 1 according to a first preferred embodiment of the present invention will be described in detail. Additionally, with figure 1 A method for operating the fuel pump 1 is described.

[0030] as from figure 1As can be seen in , the fuel pump 1 according to the invention has an inlet valve 2, an outlet valve 3, a cylinder 4, a piston 5 arranged in the cylinder 4, a heat generating actuator 6 for operating the piston 5, and a helical spring In the form of a reset element 7 for returning the piston 5 into the initial position. The fuel pump 1 is mounted, for example, in a fuel tank not shown here.

[0031] An inlet valve 2 is arranged in the end face of the cylinder 4 . The inlet valve 2 is fluidically connected to the fuel tank via a fuel line (not shown here). During the intake phase of the fuel pump 1 , fuel flows from the fuel tank through the inlet valve 2 into the compression chamber 15 formed within the cylinder 4 . The compressio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com