Soft magnetic composite material of glass insulating layer and preparation method thereof

A technology of soft magnetic composite materials and glass insulation, which is applied in the direction of magnetic materials, inorganic materials, magnetic objects, etc., can solve the problems that the magnetic properties of soft magnetic composite materials cannot be improved, and the magnetic properties are stable, so as to achieve improved mechanical properties and excellent magnetic properties. Can effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

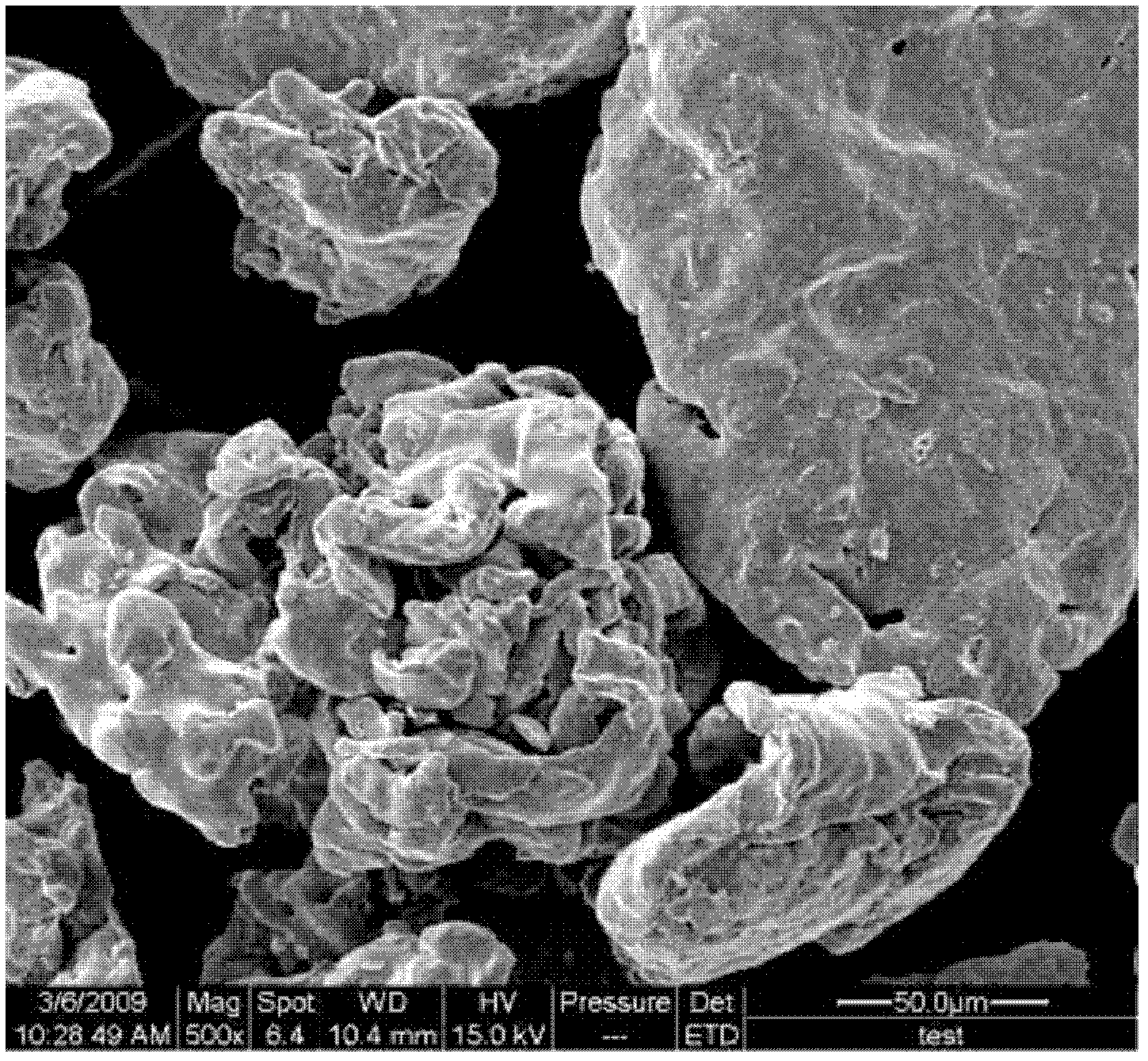

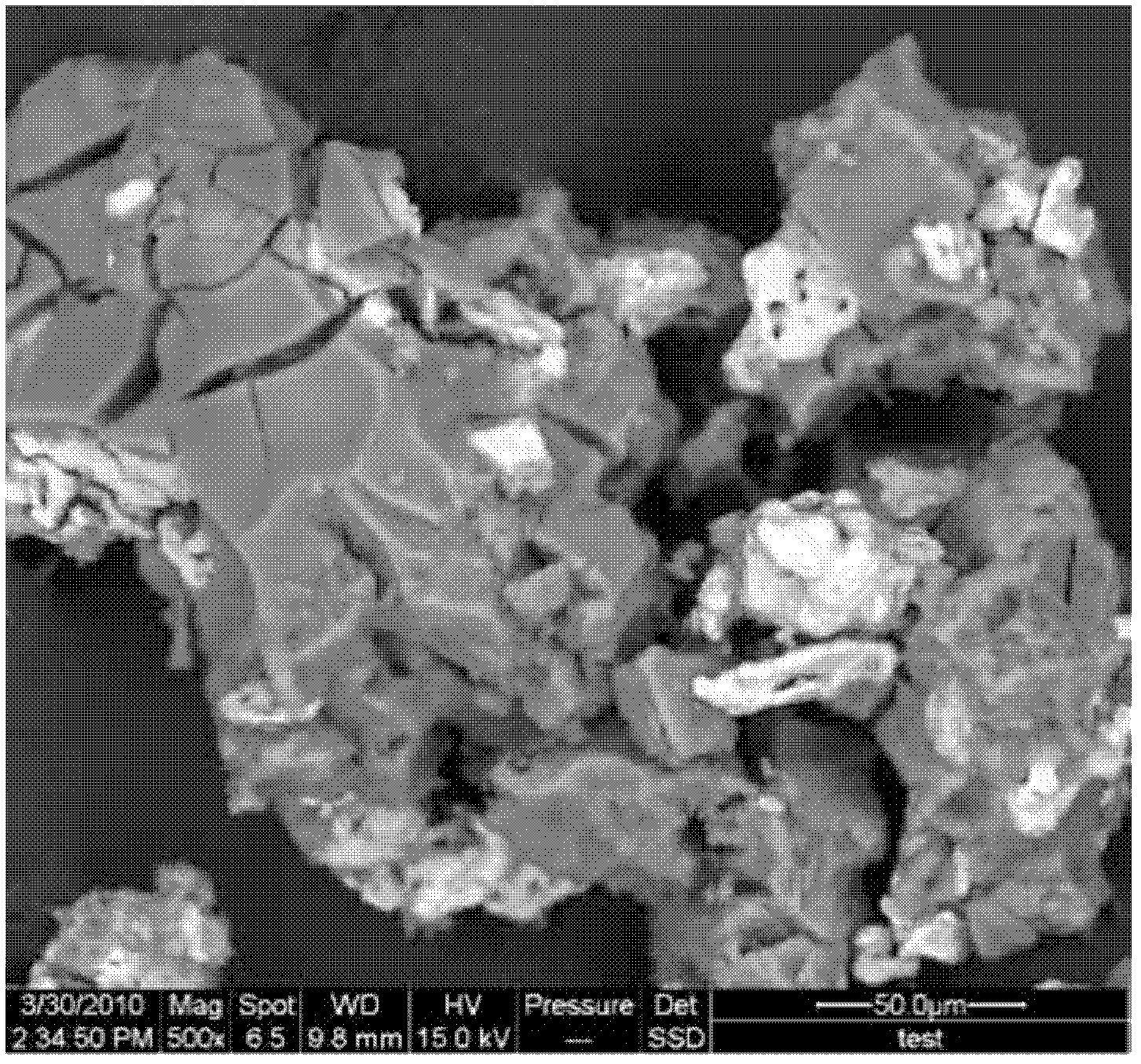

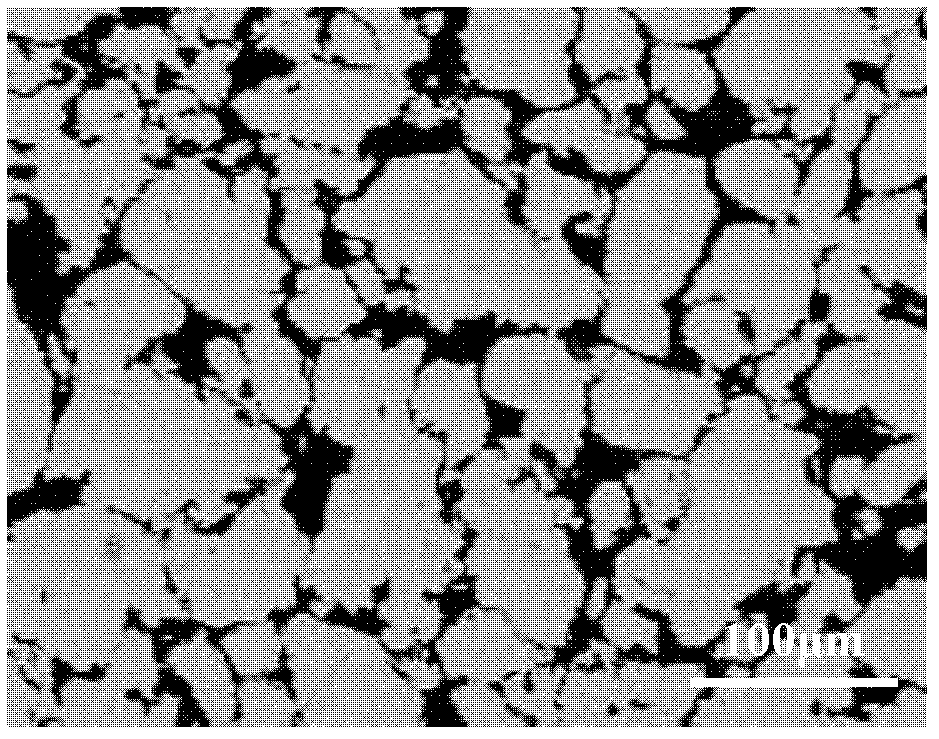

[0015] Embodiment 1: The soft magnetic composite material of the glass insulating layer in this embodiment is made by depositing amorphous material on the magnetic powder, and then annealing after cold pressing or hot pressing; the amorphous material is divided into two The film layer, the film layer close to the magnetic powder is composed of the hydrolyzate of the alkoxide, and the other film layer is composed of the hydrolyzate of the alkoxide or the mixture of the hydrolyzate of the alkoxide and the inorganic salt, and the alkoxide is a metal alkoxide or semimetal alkoxides.

[0016] The initial permeability of the soft magnetic composite material can reach more than 200, the maximum permeability can reach more than 900, the saturation magnetic induction can reach 1.5T, the coercive force is less than 250A / m, and the iron loss under the AC magnetic field of 50Hz and 1T Can be less than 3W / Kg.

specific Embodiment approach 2

[0017] Specific embodiment two: the preparation method of the soft magnetic composite material of the glass insulating layer in this embodiment is carried out according to the following steps:

[0018] 1. Mix magnetic powder, coupling agent and organic solvent to obtain mixture A. The mass fraction of coupling agent and magnetic powder in mixture A is 0.01% to 3%, and the volume ratio of organic solvent to magnetic powder is greater than 100. Stir at a speed of 300r / min, add water, the mass ratio of water to coupling agent is 1:1-20, continue stirring for 20-30min to obtain mixture B, the water is deionized water or distilled water;

[0019] Two, alkoxide is dissolved in the solution A that is prepared in the organic solvent, the concentration of alkoxide in the solution A is less than 1 / 10 of the saturation of used alkoxide in the organic solvent, then solution A is added in the mixture B, again in Stir continuously at a speed of 120 to 300 r / min for 5 to 20 minutes at a temp...

specific Embodiment approach 3

[0029] Embodiment 3: The difference between this embodiment and Embodiment 2 is that the magnetic powder in step 1 is a powder containing iron or nickel or cobalt with soft magnetic properties, the crystal structure is crystalline or amorphous, and the average particle diameter is 5 to 500 μm. Other steps and parameters are the same as in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Saturation magnetic induction | aaaaa | aaaaa |

| Coercivity | aaaaa | aaaaa |

| Iron loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com