Stator for rotary electric machine, and rotary electric machine using the stator

A technology for a rotating electrical machine and a stator is applied in the field of a stator for a rotating electrical machine and a rotating electrical machine using the stator, which can solve problems such as increasing the size of the stator, and achieve the effects of size reduction, cost reduction, and suppression of performance degradation.

Active Publication Date: 2009-07-08

DENSO CORP

View PDF1 Cites 19 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Therefore, when these unit wire ends are connected, additional space is required in the axial dire

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

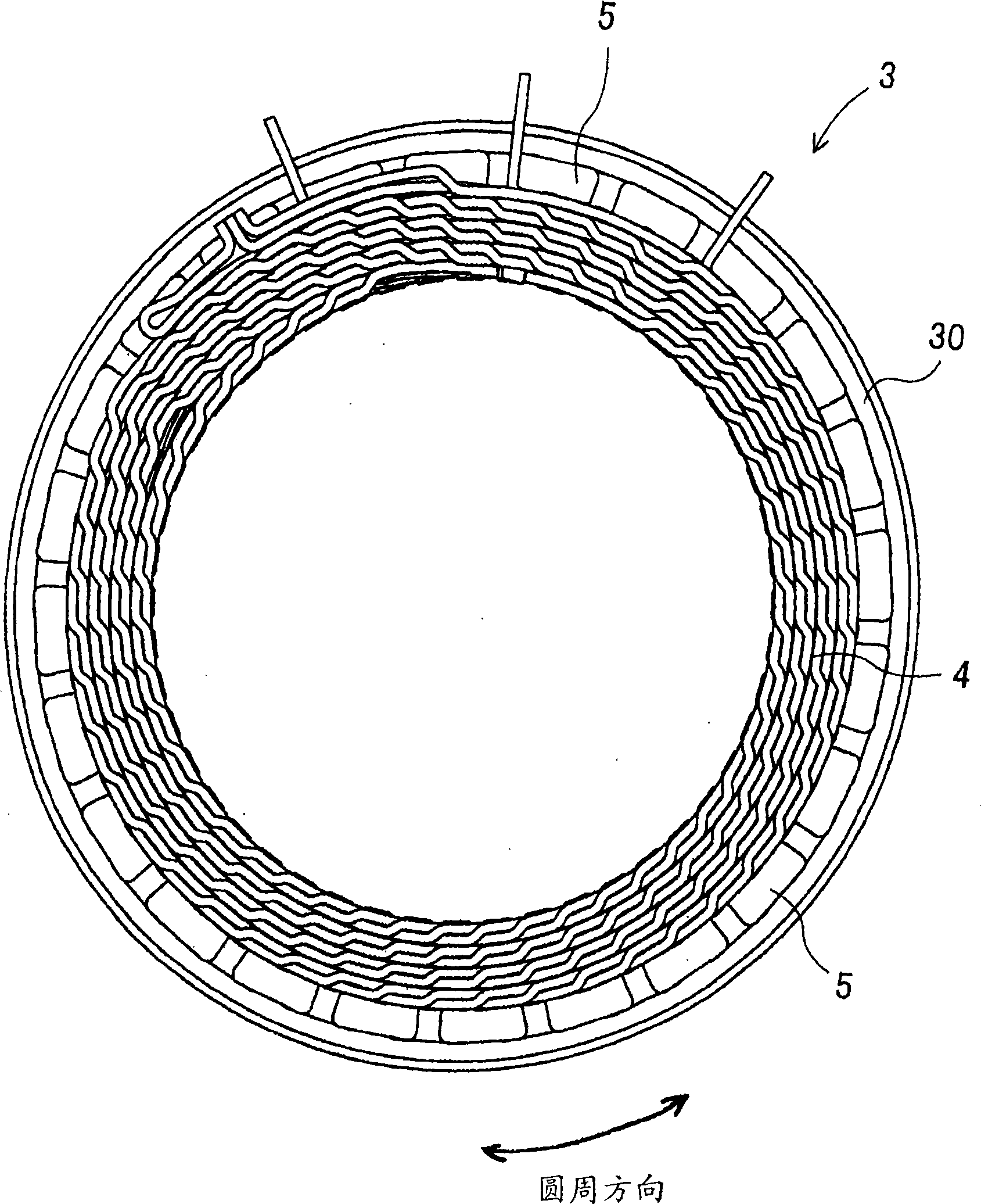

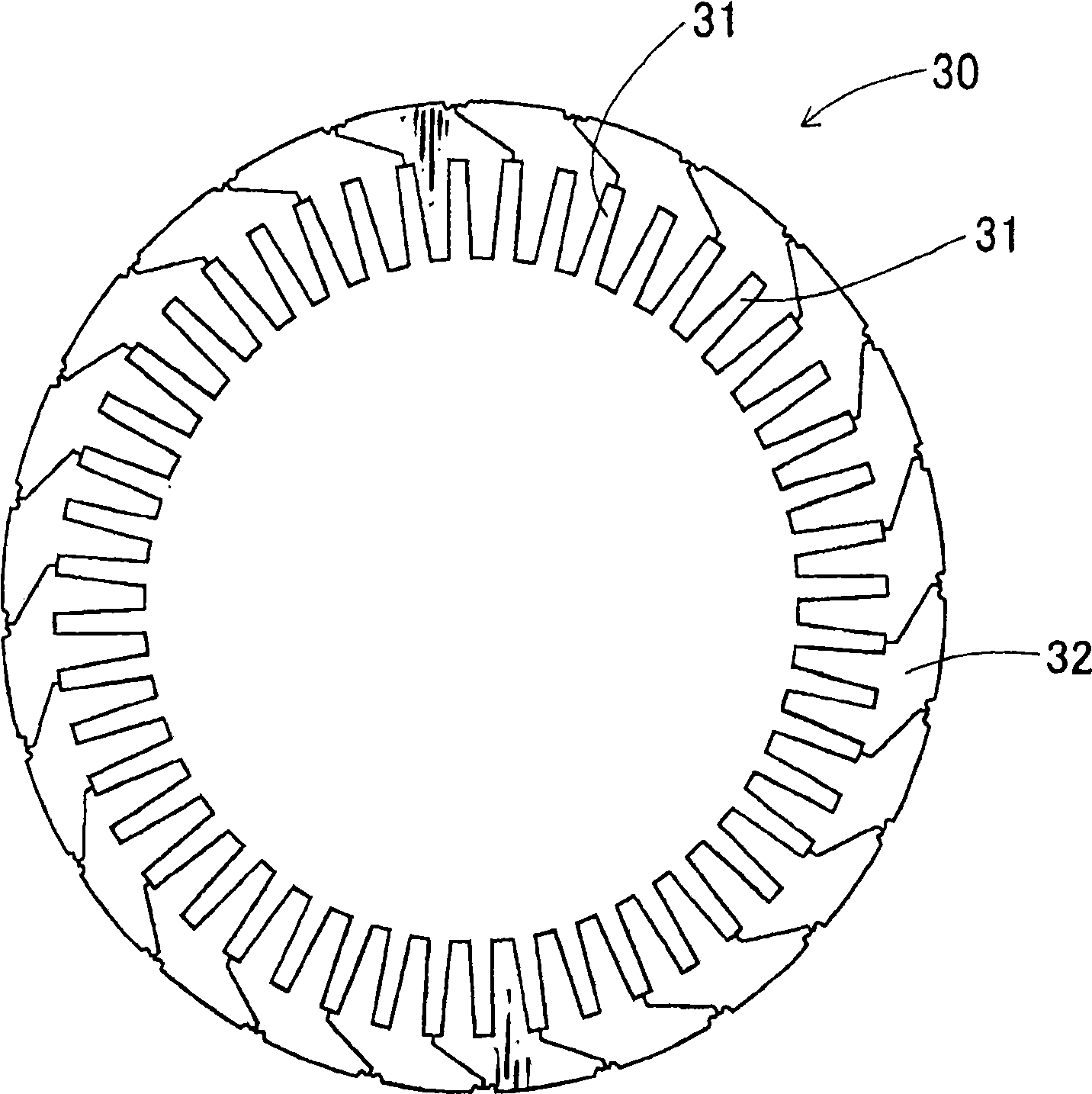

A stator for a multiple-phase rotary electric machine provided a stator core with slots and a coil formed of a plurality of windings for individual phases. Each winding has slot-accommodated portions held in different slots, turn portions connecting the slot-accommodated portions outside of the slots in an axial direction, and a return portion that connects two of the turn portions and changes a winding direction of the winding at given slots. The turn portions include specific turn portions which are the same in a circumferential position as the turn portion connected to the one of the return portion. The specific turn portions are located, in a radial direction, to be drawn apart from the rotor than the slot-accommodated portions connected to the specific turn portions.

Description

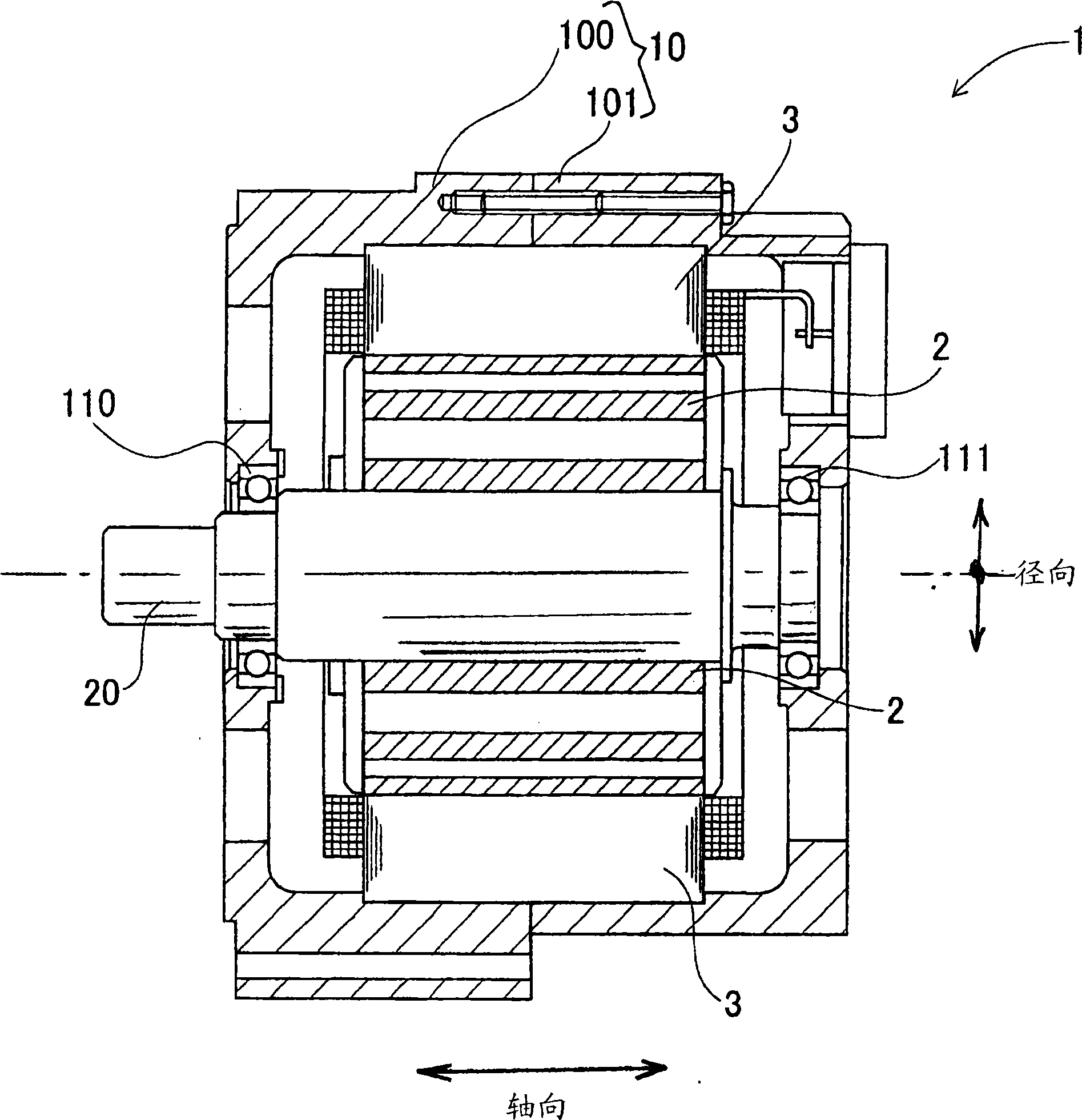

technical field [0001] The present invention relates to a stator for a rotary electric machine, and a rotary electric machine using the same. Background technique [0002] Recently, there is a need to use a miniaturized and high-power rotating electric machine as a motor or a generator. [0003] For example, in the case of a rotating electrical machine mounted on a vehicle, the space for loading such a rotating electrical machine is becoming smaller, but its output is required to be higher. [0004] Various types of rotating electrical machines have been used. For example, some such conventional rotating electric machines are disclosed in Japanese Patent Laid-Open Nos. 2002-176752 and 2004-320886. [0005] Each of these references discloses a stator for a rotating electrical machine. The stator for a rotating electric machine disclosed in each of these documents has a coil formed by continuous winding. [0006] In the rotating electric machines described in these referen...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): H02K1/12H02K3/04H02K3/28H02K15/085

Inventor 小川新一香田请司七条彰哉前川武雄

Owner DENSO CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com