Production method and production system of directional electromagnetic steel plate having excellent magnetic characteristics

A technology of electromagnetic steel sheet and manufacturing method, which is applied in the field of manufacturing directional electrical steel sheet at high-speed manufacturing line speed, can solve the problems of increased influence, longer beam residence time, and greater influence, achieve stable magnetic properties, and suppress laser irradiation The effect of increasing the width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0069] Table 1 shows examples in which iron loss characteristics of electrical steel sheets after laser irradiation were compared between cases where the method and apparatus of the present invention were used and cases where they were not.

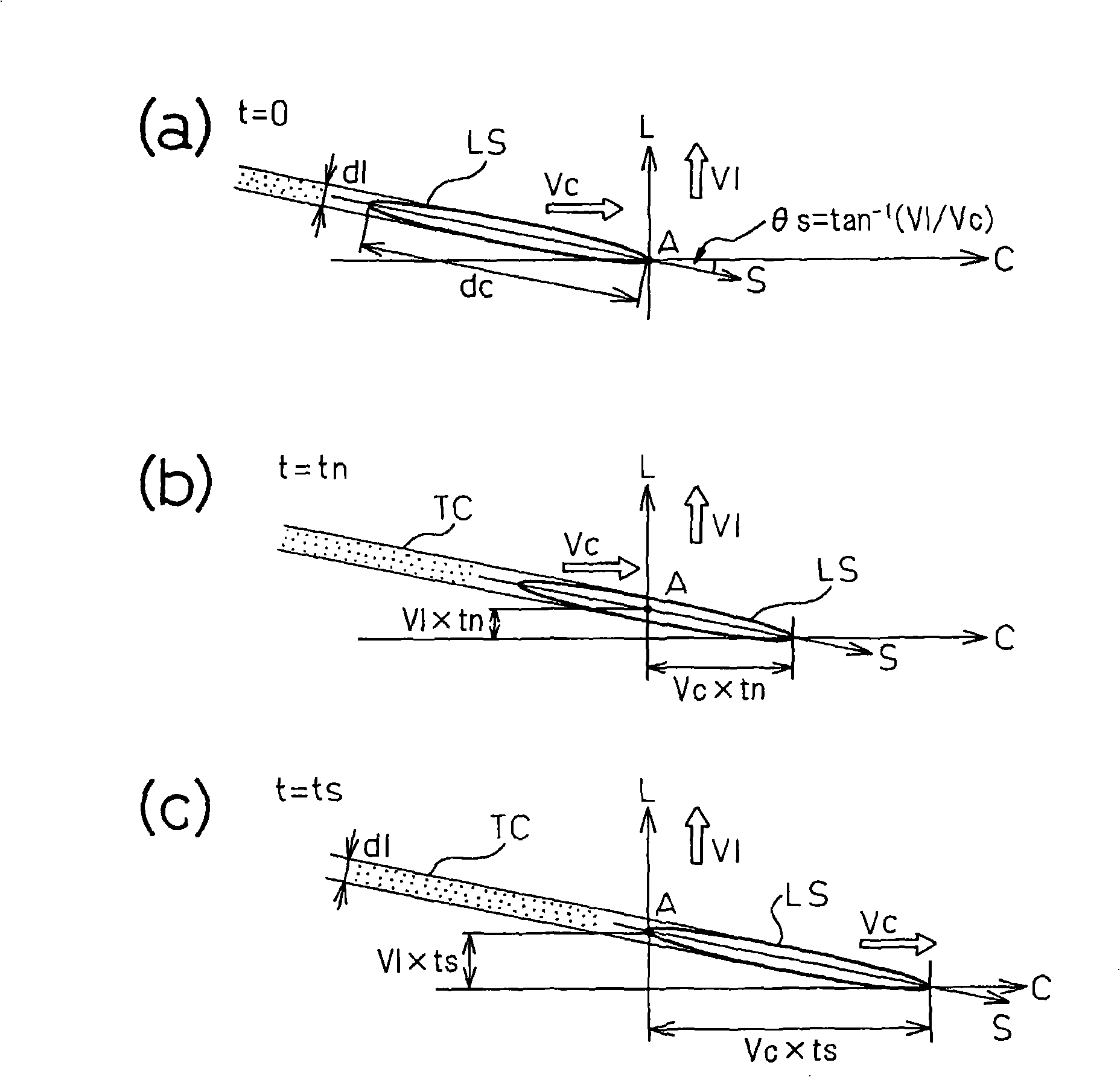

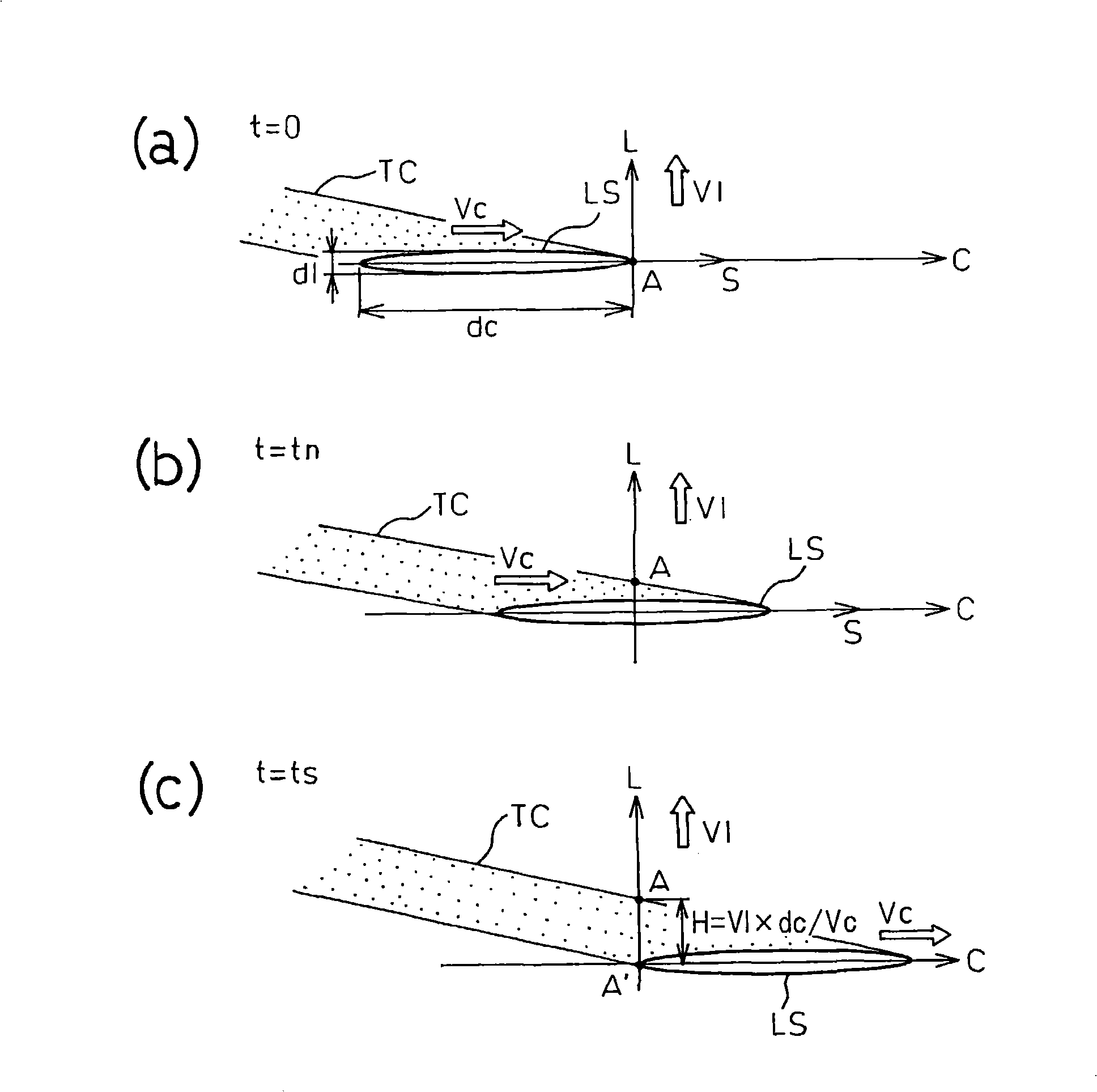

[0070]The shape of the elliptical beam focusing spot in this embodiment is that the major axis of the ellipse dc=1.0 mm and the minor axis dl=0.05 mm. The scanning speed Vc=30m / s, the rolling direction speed of the steel plate Vl=1.5m / s. The laser light intensity is 300W, and the pitch of the irradiation lines in the rolling direction is 5mm.

[0071] In Table 1, B8 is the magnetic flux density of the steel sheet generated under a magnetic force of 800 A / m. W17 / 50 is the iron loss at an AC excitation frequency of 50 Hz and a maximum magnetic flux density of 1.7 T. The comparative example is the iron loss characteristic in the case where the method of the present invention is not used, and the laser beam is irradiated with the beam scann...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com