Method for preparing ferromagnetic nano composite material with pulse-ultrasound electrodeposition

A nano-composite material, ultrasonic technology, applied in the direction of electrolytic coatings, coatings, etc., can solve the problem that a single material is difficult to meet the demand, and achieve the effect of low cost and simple method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

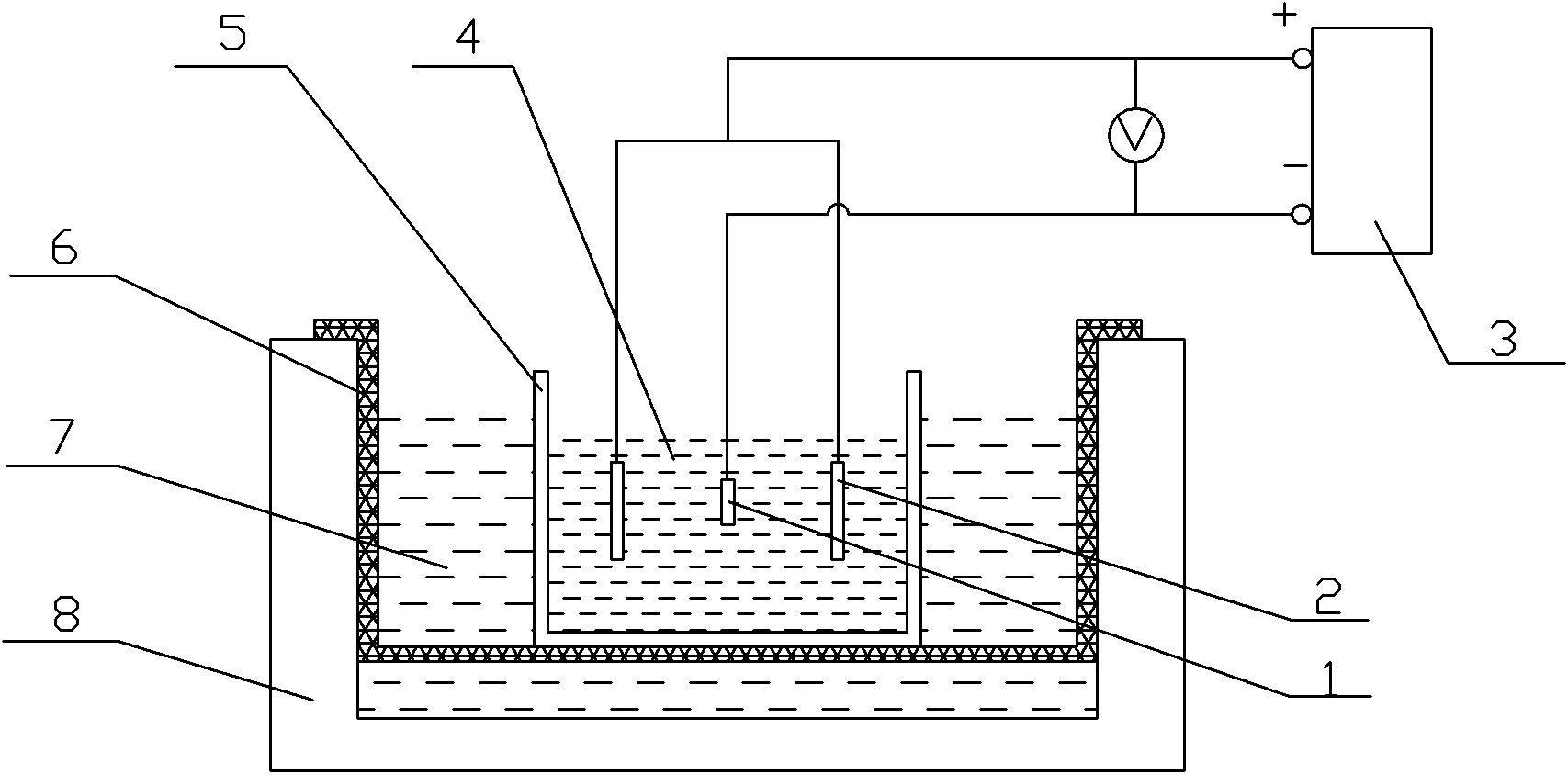

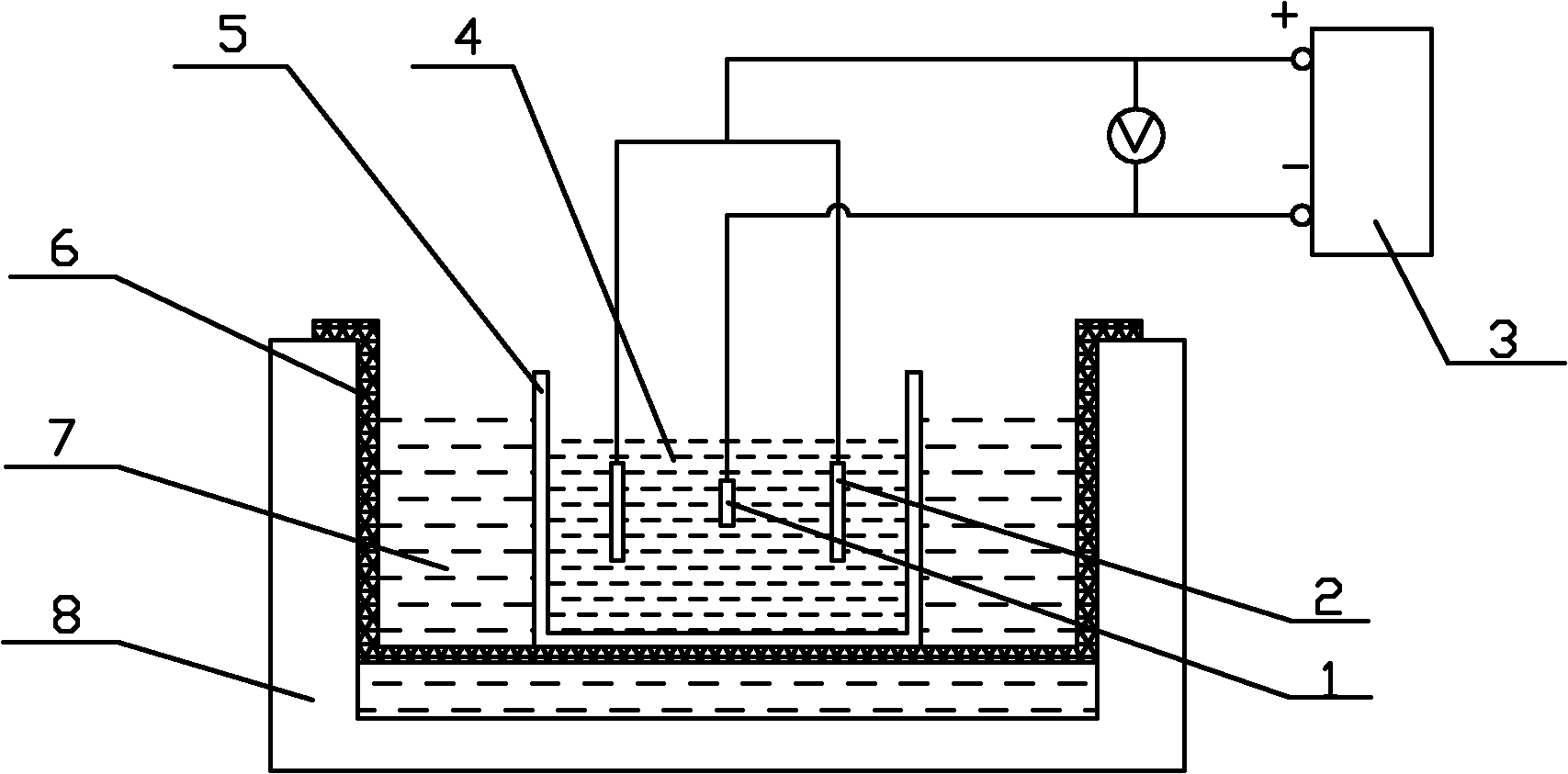

[0067] Specific embodiments of the present invention are shown in the accompanying drawings, and the specific implementation steps of the described pulse-ultrasonic electrodeposition to prepare ferromagnetic nanocomposites are:

[0068] 1. Perform mechanical pretreatment on the sample: rough grinding with sandpaper to remove foreign matter such as burrs and oxides on the surface of the sample to reduce surface roughness.

[0069] 2. Pre-treatment of the sample: degreasing, derusting, electrolytic polishing and activation. The components of the solution for degreasing the matrix are: sodium hydroxide 90g / l, sodium phosphate 60g / l, washing powder 4g / l, temperature 60°C, time 8min.

[0070] Rust removal solution formula: sulfuric acid 180g / l, hydrochloric acid 55g / l, OP emulsifier 4g / l, thiourea 4g / l, sodium lauryl sulfate 0.04g / l, temperature at room temperature, time 8min.

[0071] Electropolishing solution formula and process parameters: phosphoric acid 72%, chromic acid 23%,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com