Premelting slag used for producing container steel of hydrogenation reactor and application thereof

A technology of hydrogenation reactor and pre-melted slag, which is applied in the application field of production of hydrogenation reactor container steel, can solve the problems of not being able to meet the requirements of low silicon, and achieve the effects of improving product competitiveness, increasing productivity, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

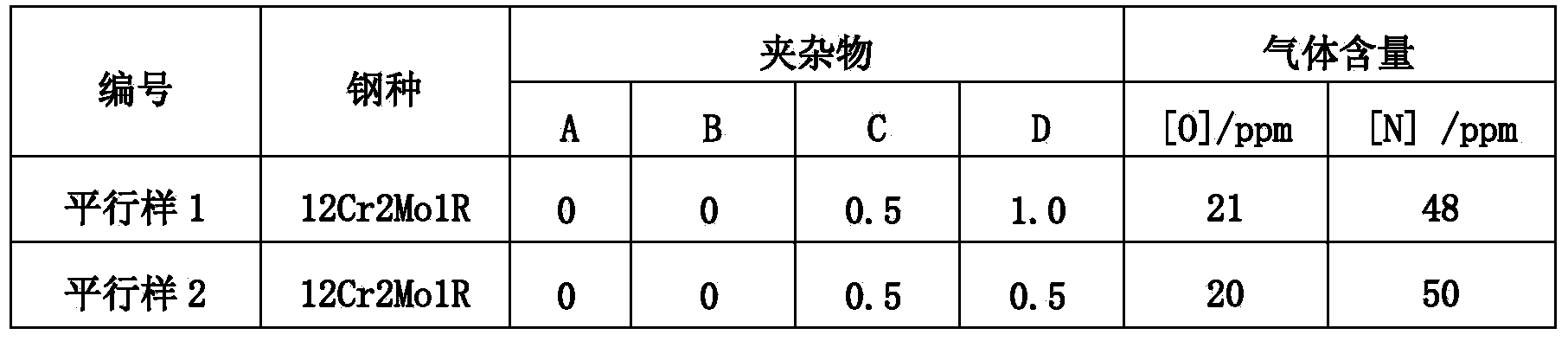

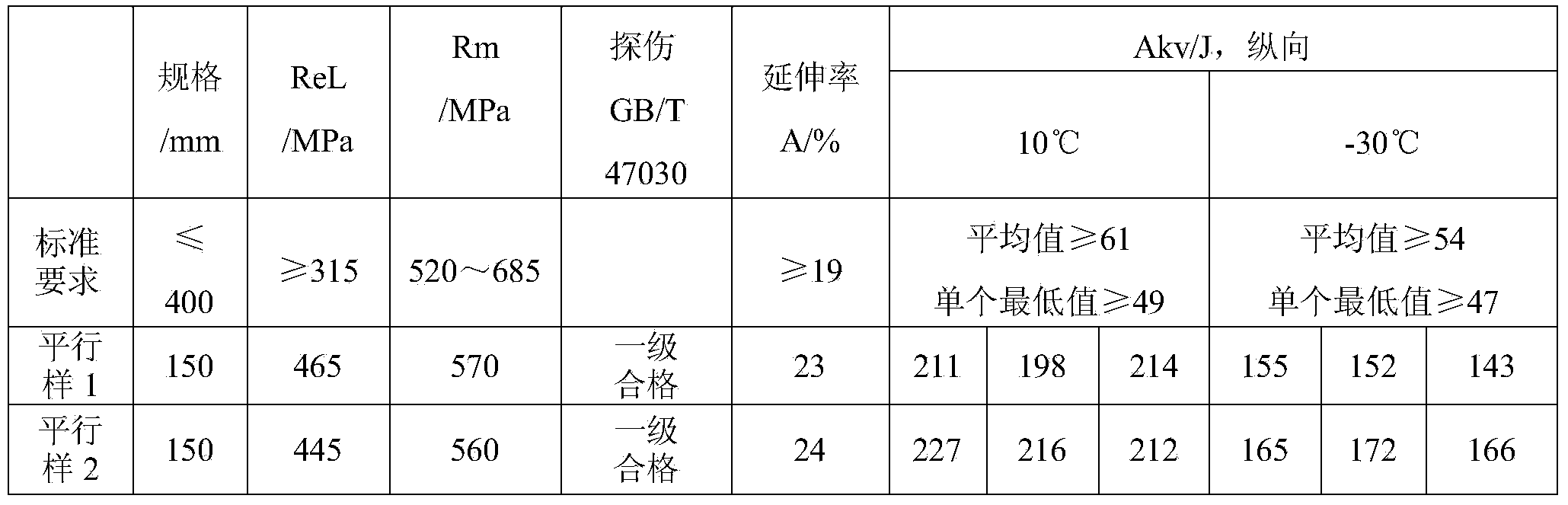

[0030] The production process of the present invention for producing 120-160 mm thick high-purity hydrogenation reactor vessel steel includes the electroslag remelting smelting step and the steel plate rolling step as in the prior art, and the electroslag remelting smelting step adopts low-frequency bipolar The series slab electroslag remelting furnace is used for remelting and smelting. The difference is that the chemical composition and weight percentage of the electrode base material of the low-frequency bipolar series slab electroslag remelting furnace of the present invention meet the following requirements:

[0031] C: 0.08~0.12%, Si: 0.05~0.12%, Mn: 0.30~0.45%, P: ≤0.012%, S: ≤0.010%, Cr: 2.10~2.25%, Ni: ≤0.18%, Mo: 0.95~ 1.10%, Cu: ≤0.12%, Sn: ≤0.005%, As: ≤0.004%, Sb: ≤0.003%, N: ≤0.008%, O≤0.003%, and the rest are Fe and una...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com