Aluminizing method of circular ring chain

A technology of circular link chain and aluminizing, which is applied in coating, metal material coating process, hot-dip plating process, etc. It can solve the problems of not being too high in treatment temperature, reducing the aluminum concentration on the surface of the substrate, and affecting costs and benefits. Improve the ability to withstand tensile and impact loads, improve contact fatigue performance, and excellent corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

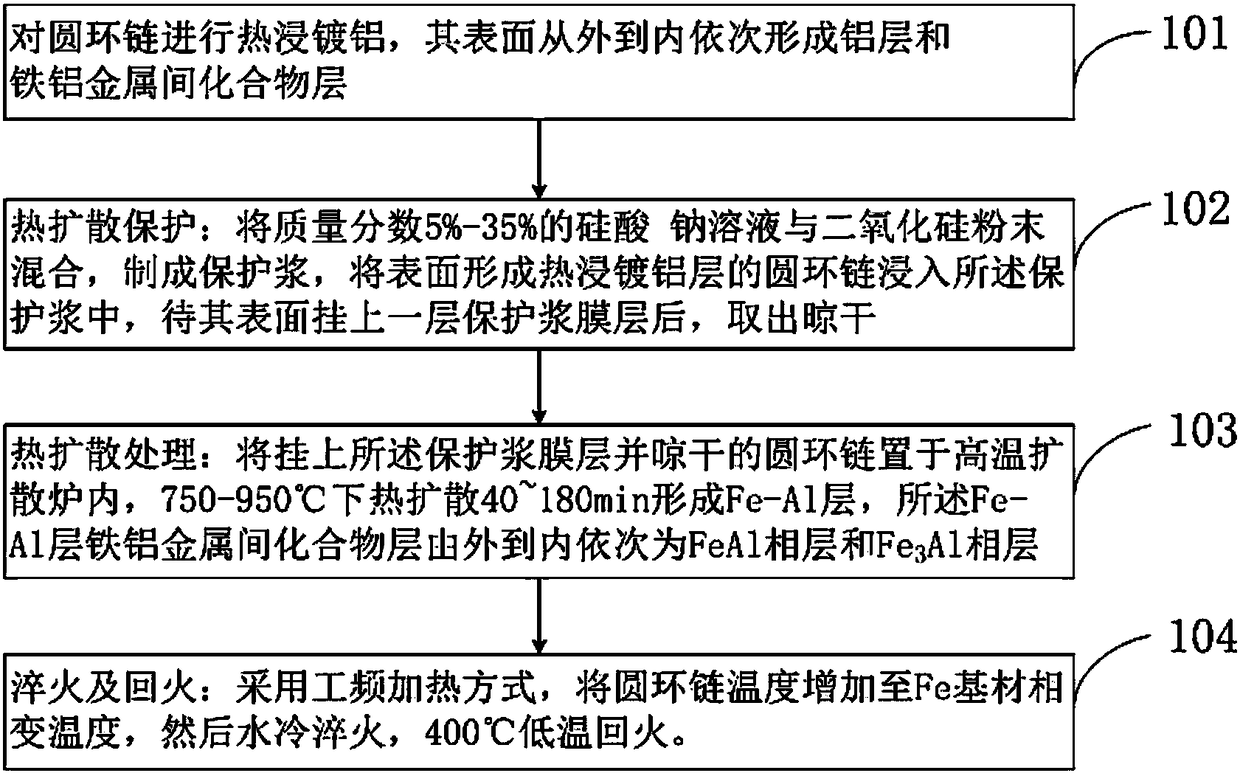

Method used

Image

Examples

Embodiment 1

[0038] In this embodiment, the material protection and rapid thermal diffusion treatment method applied to the aluminized steel of the circular link chain is provided as follows:

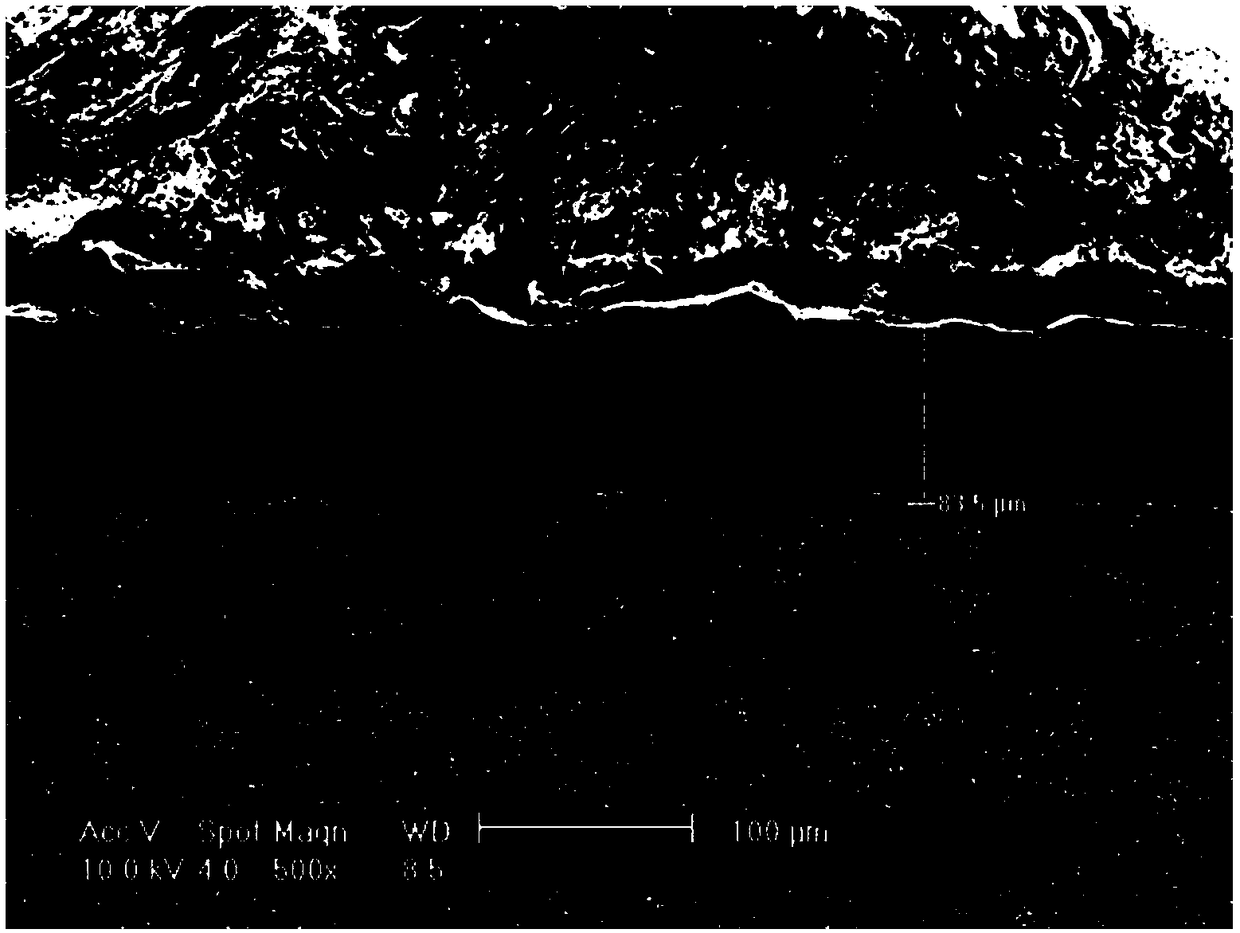

[0039] Using the hot-dip plating process, immerse the 23MnNiMoCr54 material circular chain in a 730°C hot-dip aluminum plating furnace for 3 minutes. Such as figure 2Shown is the cross-sectional appearance of the round-link chain after hot-dip aluminizing in this embodiment, and an aluminum layer of 18 μm and an iron-aluminum layer of 10 μm are formed from the surface in sequence from outside to inside. The outer layer of the iron-aluminum layer is Fe 2 Al 5 phase, the middle layer is FeAl 3 phase, the inner layer is Fe 3 Al phase.

[0040] Prepare a sodium silicate solution with a mass fraction of 35%, add silica powder with a particle size of 800 mesh, and mix at a mass ratio of 1:2.7 to form a protective slurry. Invade the round link chain into the protective slurry and stay for 2 minutes ...

Embodiment 2

[0045] In this embodiment, the material protection and rapid thermal diffusion treatment method applied to the aluminized steel of the circular link chain is provided as follows:

[0046] Using the hot-dip plating process, immerse the 25MnV material circular chain in a 780°C hot-dip aluminum plating furnace for 10 minutes. The round link chain after hot-dip aluminum plating forms an aluminum layer of 70 μm and an iron-aluminum layer of 50 μm from the surface in sequence from the outside to the inside. The outer layer of the iron-aluminum layer is Fe 2 Al 5 phase, the middle layer is FeAl 3 phase, the inner layer is Fe 3 Al phase.

[0047] Prepare a sodium silicate solution with a mass fraction of 15%, add silica powder with a particle size of 1000 mesh, and mix according to a mass ratio of 1:3.7 to form a protective slurry. Invade the round link chain into the protective slurry and stay for 2 minutes to ensure that the surface is covered with protective slurry and then re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com