Steel for subway wheels and wheel production method

A production method and wheel technology, applied in furnace types, furnaces, heat treatment furnaces, etc., can solve problems such as the reduction of toughness indicators and the risk of affecting vehicle operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1- Embodiment 3

[0040] A steel for subway wheels, including the following mass percentage elements: as shown in Table 1, the balance not listed in Table 1 is Fe and unavoidable impurities.

Embodiment 1

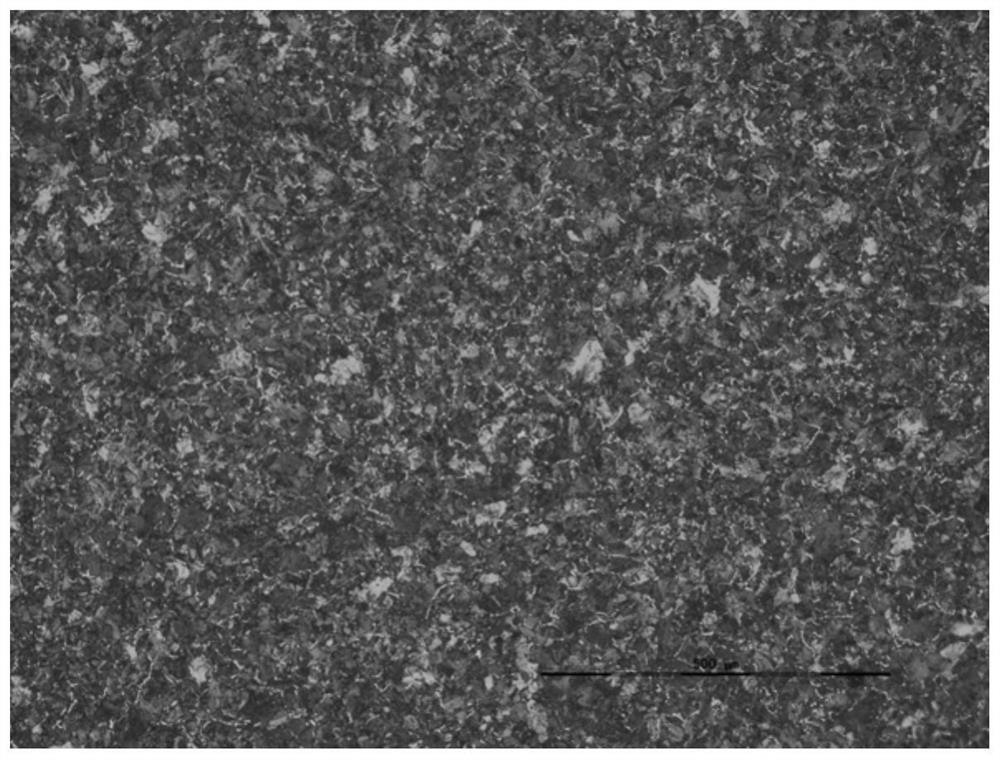

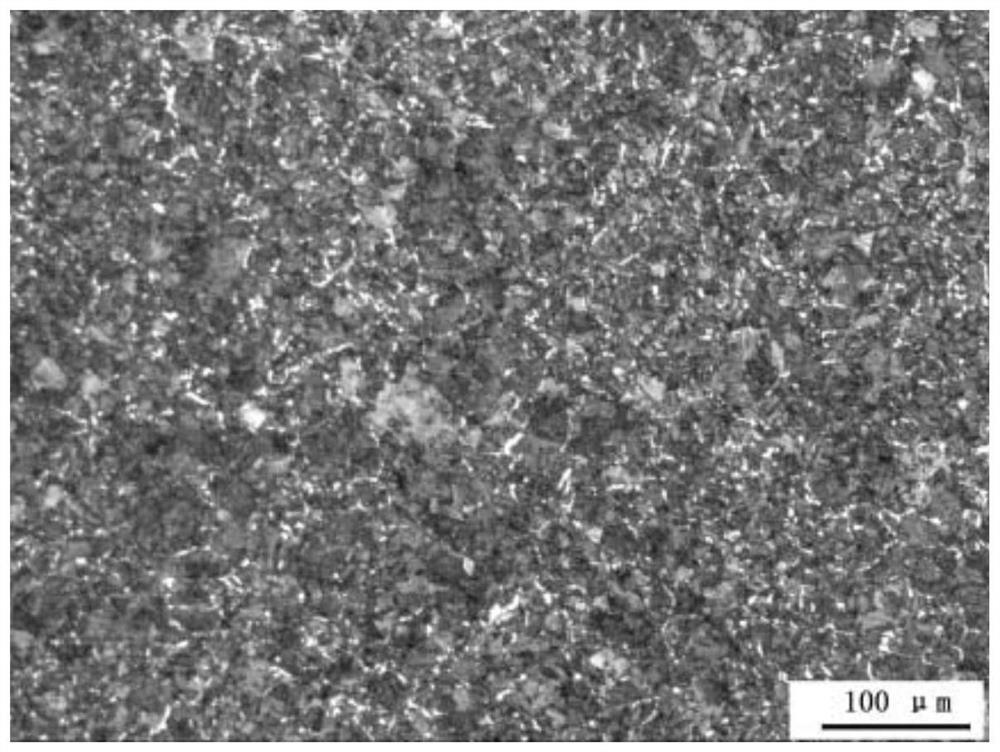

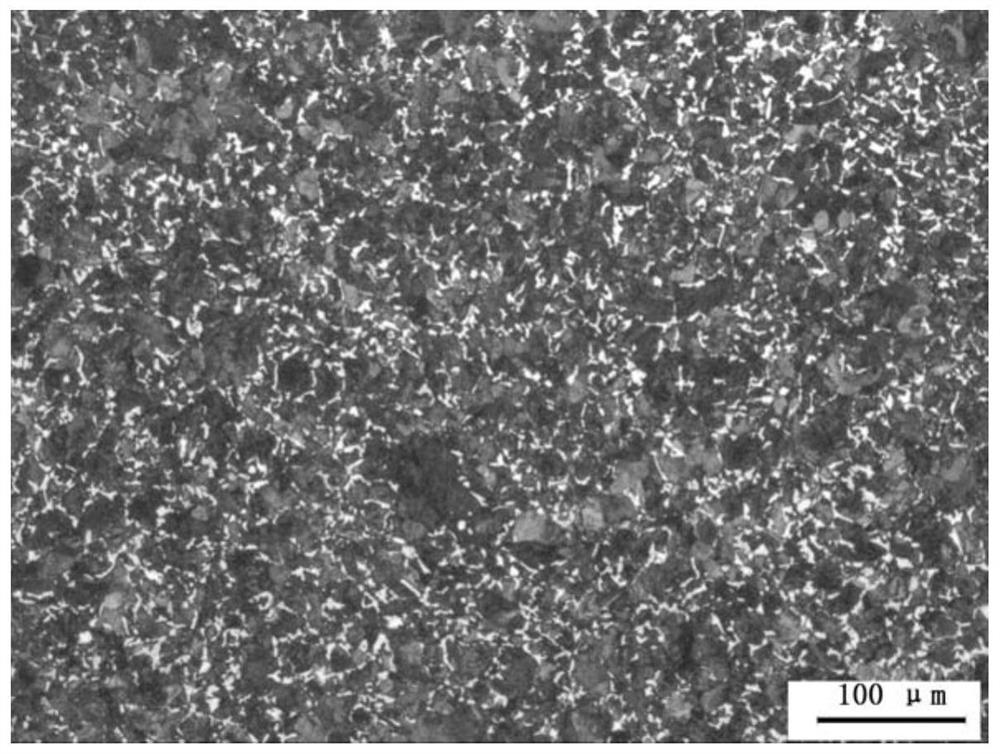

[0048] Example 1 The steel used for subway wheels is used to produce wheels. The heat treatment process is as follows: first, after holding the heat for 2.5 hours at 850°C, the rim is sprayed with water to cool the metal inside the rim to 530°C at a cooling rate of 1°C / s-4°C / s. Next, temper at 500°C for 4.5 hours at last, and use the same heat treatment process for Comparative Example 1 and Comparative Example 2. The wheel rim prepared in this embodiment is pearlite+ferrite (see Figure 1-Figure 3 ), the structure of Example 1 is pearlite+ferrite 2.4%; the structure of Comparative Example 1 is pearlite+ferrite 6.7%, and the structure of Comparative Example 2 is pearlite+ferrite 5.9%.

[0049] The steels of the composition of Comparative Example 1 and Comparative Example 2 were treated according to the above-mentioned heat treatment method of Example 1.

[0050] The mechanical properties of the wheel of this embodiment are shown in Table 2, and its toughness, strength and hard...

Embodiment 2

[0052] Example 2 The steel used for subway wheels is used to produce wheels. The heat treatment process is as follows: first, after holding the heat for 2.5 hours at 842°C, the rim is sprayed with water to cool the metal inside the rim to 530°C at a cooling rate of 1°C-4°C / s. In the following, the final tempering treatment was performed at 480° C. for 5.0 hours, and the same heat treatment process was adopted for Comparative Example 1 and Comparative Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com