Self-lubricating alloy high-hardness bearing

A high-hardness, self-lubricating technology, used in bearing components, shafts and bearings, mechanical equipment, etc., can solve the problems of insufficient ball hardness and large wear, and achieve the effect of long service life, improved service life and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

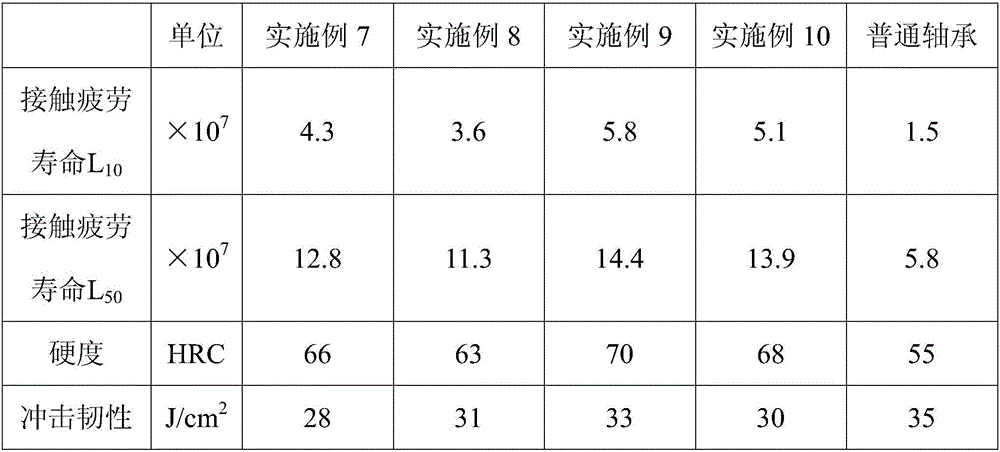

Examples

Embodiment 1

[0028] The invention proposes a self-lubricating alloy high-hardness bearing, which includes a bearing outer ring, balls and a bearing inner ring, wherein the outer raceway surface of the bearing inner ring is coated with polytetrafluoroethylene, and the ball is an iron alloy, and its components are calculated by weight percentage Including: C: 0.2%, Si: 0.6%, B: 0.04%, V: 0.3%, Ni: 0.05%, Mo: 0.3%, Nb: 0.13%, Al: 0.4%, Cr: 3.2%, Zr: 0.1 %, Sc: 0.05%, Y: 0.1%, S≤0.015%, P≤0.02%, and the balance is Fe.

Embodiment 2

[0030]The invention proposes a self-lubricating alloy high-hardness bearing, which includes a bearing outer ring, balls and a bearing inner ring, wherein the outer raceway surface of the bearing inner ring is coated with polytetrafluoroethylene, and the ball is an iron alloy, and its components are calculated by weight percentage Including: C: 0.5%, Si: 0.3%, B: 0.07%, V: 0.1%, Ni: 0.08%, Mo: 0.2%, Nb: 0.17%, Al: 0.2%, Cr: 4.0%, Zr: 0.07 %, Sc: 0.08%, Y: 0.07%, S≤0.015%, P≤0.02%, and the balance is Fe.

[0031] The preparation process of the ball includes: smelting, casting and heat treatment; wherein the heat treatment includes: austenitizing treatment, austempering and tempering.

Embodiment 3

[0033] The invention proposes a self-lubricating alloy high-hardness bearing, which includes a bearing outer ring, balls and a bearing inner ring, wherein the outer raceway surface of the bearing inner ring is coated with polytetrafluoroethylene, and the ball is an iron alloy, and its components are calculated by weight percentage Including: C: 0.25%, Si: 0.55%, B: 0.045%, V: 0.28%, Ni: 0.055%, Mo: 0.29%, Nb: 0.135%, Al: 0.38%, Cr: 3.3%, Zr: 0.095 %, Sc: 0.055%, Y: 0.095%, S≤0.015%, P≤0.02%, and the balance is Fe.

[0034] The preparation process of the ball includes: smelting, casting and heat treatment; wherein the heat treatment includes: austenitizing treatment, austempering and tempering.

[0035] The temperature of austenitizing treatment is 920°C, and the time of austenitizing treatment is 3h.

[0036] The specific operation of isothermal quenching is as follows: air-cool the austenitized material to 400°C, then place it in a nitrate salt bath for 38 minutes, the tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com