A rolling bearing with high toughness and high hardness

A rolling bearing, high hardness technology, applied in the field of bearings, can solve the problems of difficulty in meeting the development needs of mechanical parts, low contact fatigue strength, poor life reliability, etc., to achieve inhibition of precipitation nucleation or growth, good contact fatigue performance, and reduce contact The effect of fatigue life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

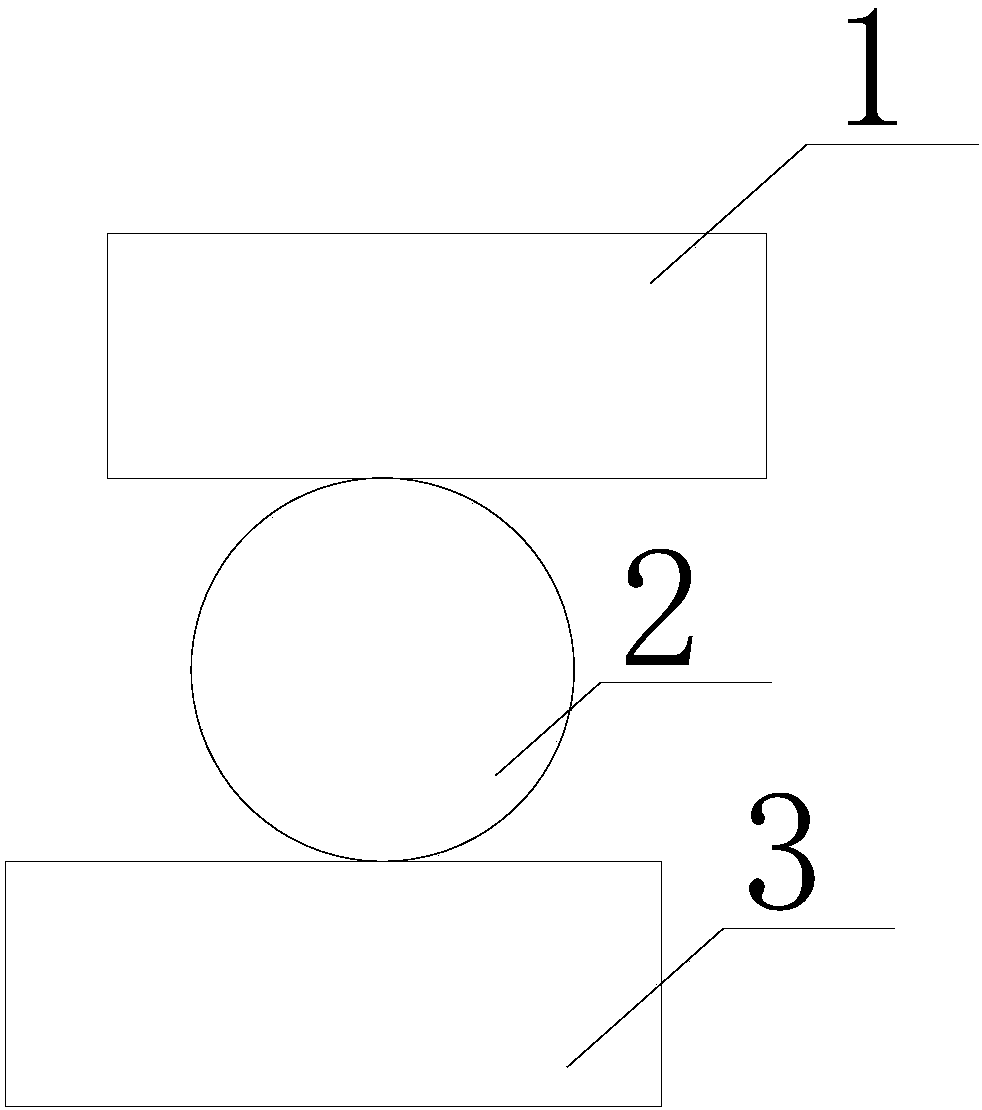

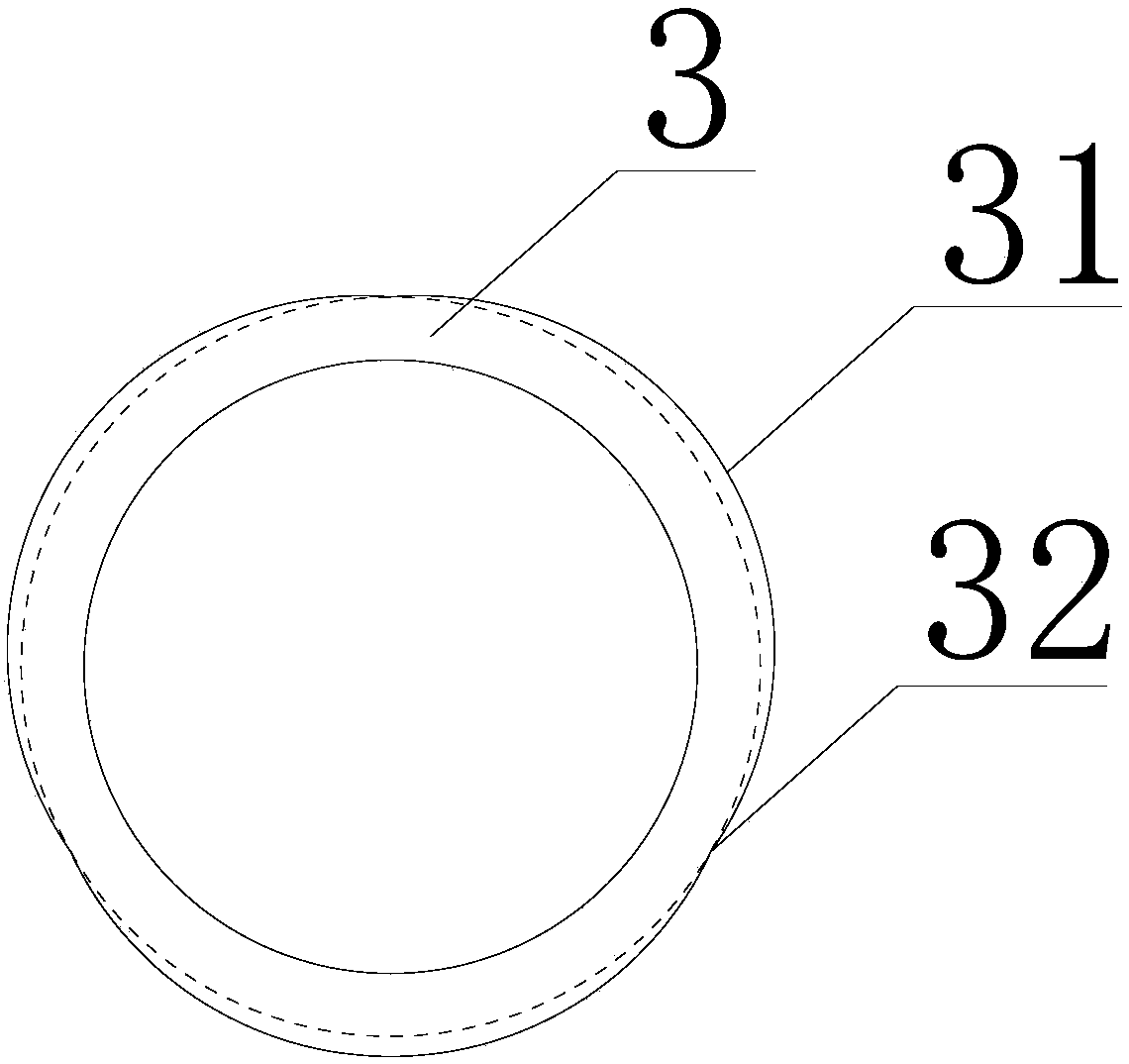

[0030] likefigure 1 and figure 2 as shown, figure 1 It is a sectional view of a rolling bearing with high toughness and high hardness proposed by the present invention, figure 2 It is a structural schematic diagram of the inner ring of a rolling bearing with high toughness and high hardness proposed by the present invention.

[0031] refer to figure 1 and figure 2 , a high-toughness and high-hardness rolling bearing proposed by the present invention includes a bearing outer ring 1, rolling elements 2, and a bearing inner ring 3. Protruding part 31, three protruding parts 31 are connected in sequence, and a concave part 32 is formed at the junction of two adjacent protruding parts 31; the protruding part 31 and the concave part 32 are arc lines; the three protruding parts 31 are along the The circumferential direction of the ring 3 is evenly distributed on the outer raceway surface.

[0032] The components of the bearing inner ring 3 include by weight percentage: C: 0.6...

Embodiment 2

[0037] A high-toughness and high-hardness rolling bearing proposed by the present invention includes a bearing outer ring 1, rolling elements 2, and a bearing inner ring 3. The outer raceway surface of the bearing inner ring 3 includes three protrusions protruding toward the outer side of the bearing inner ring 3 31, the three raised parts 31 are connected in turn, and a concave part 32 is formed at the junction of two adjacent raised parts 31; the raised part 31 and the concave part 32 are both arcs; the three raised parts 31 are along the inner ring of the bearing 3 are evenly distributed on the outer raceway surface in the circumferential direction.

[0038] The components of the bearing inner ring 3 include by weight percentage: C: 0.7%, Si: 0.34%, N: 0.4%, B: 0.12%, Mn: 0.3%, V: 0.2%, W: 0.1%, Mo: 0.22 %, Nb: 0.12%, Al: 0.26%, Cr: 3.41%, Ce: 0.07%, S≤0.015%, P≤0.02%, and the balance is Fe.

[0039] The preparation process of the bearing inner ring 3 includes: smelting, c...

Embodiment 3

[0043] A high-toughness and high-hardness rolling bearing proposed by the present invention includes a bearing outer ring 1, rolling elements 2, and a bearing inner ring 3. The outer raceway surface of the bearing inner ring 3 includes three protrusions protruding toward the outer side of the bearing inner ring 3 31, the three raised parts 31 are connected in turn, and a concave part 32 is formed at the junction of two adjacent raised parts 31; the raised part 31 and the concave part 32 are both arcs; the three raised parts 31 are along the inner ring of the bearing 3 are evenly distributed on the outer raceway surface in the circumferential direction.

[0044] The components of the bearing inner ring 3 include by weight percentage: C: 0.62%, Si: 0.16%, N: 0.47%, B: 0.1%, Mn: 0.36%, V: 0.12%, W: 0.13%, Mo: 0.19 %, Nb: 0.14%, Al: 0.23%, Cr: 3.3881%, Ce: 0.09%, S≤0.015%, P≤0.02%, and the balance is Fe.

[0045] The preparation process of the bearing inner ring 3 includes: smelt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com