Bainite steel for railroad carriage wheel

A technology for bainitic steel and railway vehicles, which is applied in the direction of furnace types, furnaces, heat treatment furnaces, etc. It can solve problems such as fatigue, peeling, poor thermal crack resistance, and low yield strength, so as to reduce wheel rim cracks and service life Long-lasting and safe to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

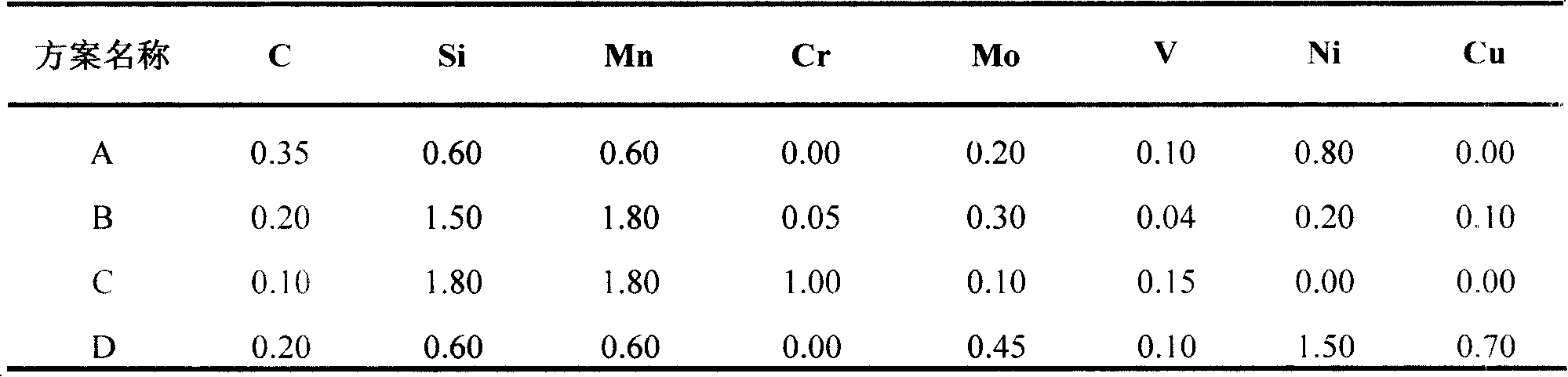

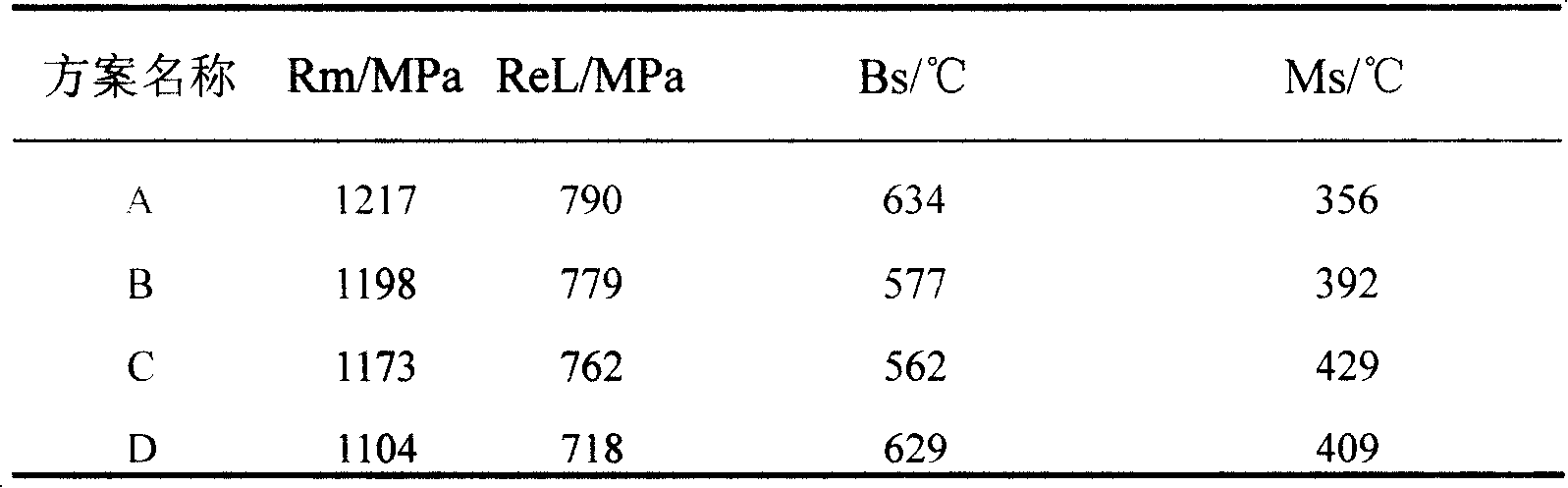

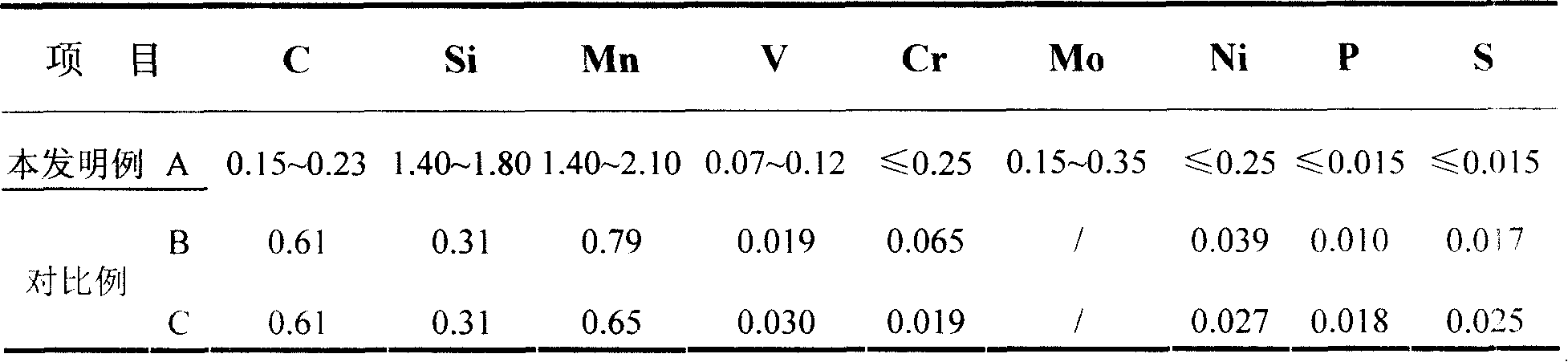

[0064] Through the comparative analysis of the above parameter data, the design schemes A, B, C and D all meet the design requirements. However, based on the relationship between the structure and properties of carbide-free bainitic steel, the complexity of the wheel production process, and the minimization of precious elements, after comprehensive consideration, the chemical composition and content of Scheme B have been adjusted appropriately , as an embodiment of the present invention, the chemical composition is shown in Table 5.

[0065] Table 5 Chemical composition / wt% of carbide-free bainitic steel

[0066]

[0067] According to the chemical composition in Table 5, the finished wheels were smelted, rolled, and heat treated. After inspection and analysis: the microstructure within the range of 50-70mm from the wheel tread is mainly carbide-free bainite structure, containing only a small amount of granular bainite body; the mechanical properties are shown in Table 4, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com