Aviation heavy-duty gear and preparation method thereof

A gear and aviation technology, applied in the field of aviation parts manufacturing, can solve the problems of low process control accuracy, restricting the development of mechanical equipment, and heavy structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The invention provides a method for preparing an aviation heavy-duty gear, comprising the following steps:

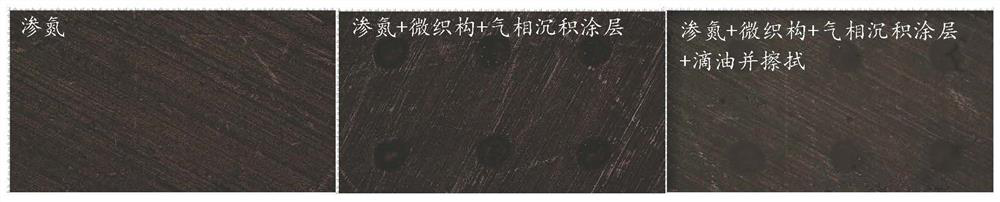

[0032] performing laser micro-texture treatment on the tooth surface of the heavy-duty gear base, forming a laser micro-texture layer on the tooth surface, and obtaining a micro-textured heavy-duty gear;

[0033] Carrying out carbonitriding, quenching and tempering sequentially on the surface of the micro-textured heavy-duty gear to form a penetration strengthening layer to obtain a strengthened heavy-duty gear;

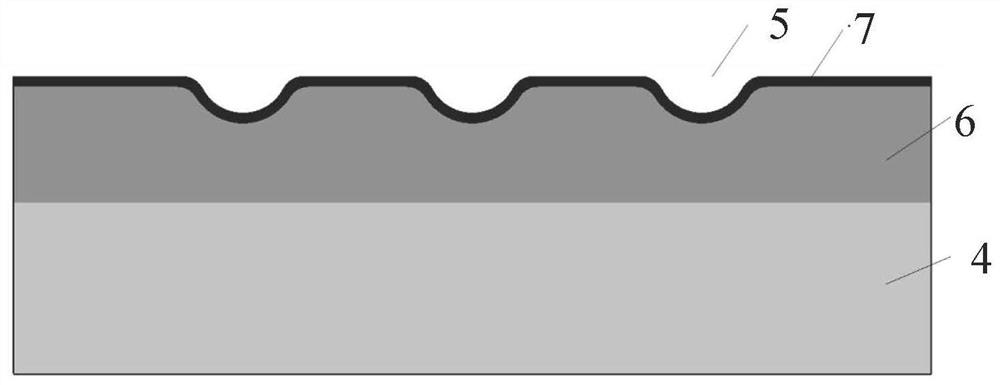

[0034] After plasma cleaning the strengthened heavy-duty gear, vapor deposition is carried out to form a gradient hard anti-friction coating on the penetration enhancement layer to obtain an aviation heavy-duty gear; the gradient hard anti-friction layer includes deposition on the A Cr layer on the infiltration enhancement layer, a CrN layer deposited on the Cr layer, a CrWCN layer deposited on the CrN layer, and a WC-DLC layer deposited on the CrWCN la...

Embodiment 1

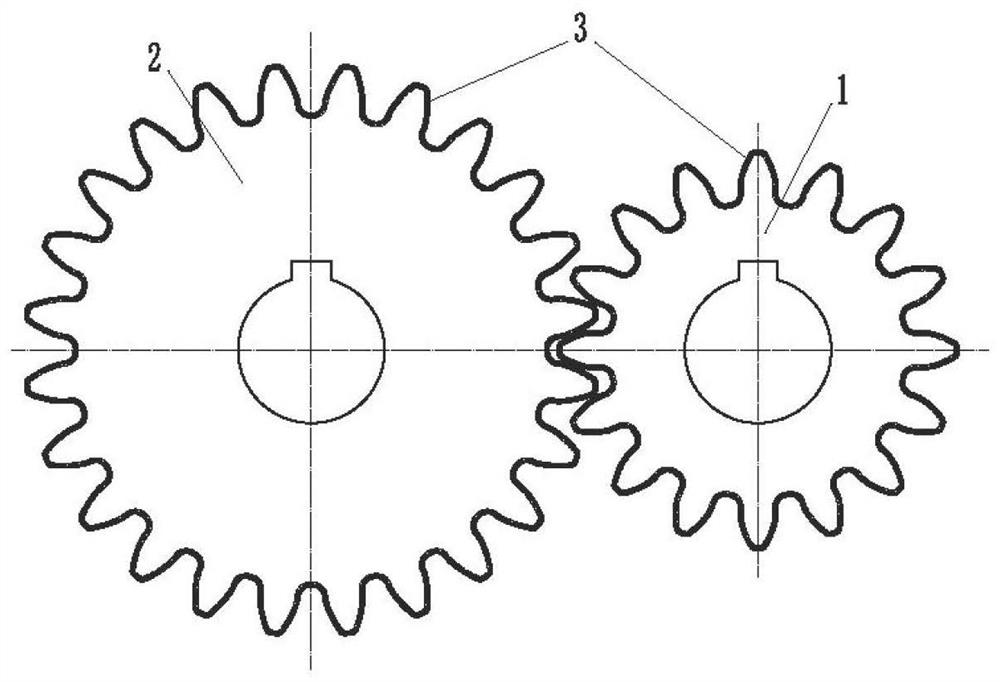

[0080]Put the planetary gear (9310 steel, outer diameter 82.43mm, modulus 4.5) and sun gear (9310 steel, outer diameter 118.36mm, modulus 4.5) into deionized water and water-based cleaning agent for ultrasonic cleaning, specifically The process parameters are shown in Table 2, and the cleaned gear is obtained;

[0081] A picosecond laser is used to micro-texture the cleaned gears. The laser processing parameters are set to a pulse width of 10 ps, a frequency of 405.5 kHz, a laser power of 11 W, and a pulse number of 15. The structure parameter is a laser micro-textured layer with a diameter of 45 μm, a depth of 10 μm, and an interval of 2 times the diameter of the micro-pit;

[0082] Carry out heat treatment on the gear with the above-mentioned laser micro-texture layer, and the conditions of carbonitriding heating are: pass through the mixed infiltration agent of methanol, acetone and ammonia for carbonitriding, the co-infiltration temperature is 925 ℃, and the holding time...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com