Fine flaky-cryptocrystalline mixed graphite separation technique

A technology of aphanitic and fine scales, which is applied in the field of fine scale-aphanitic mixed graphite beneficiation technology, can solve the problems of high viscosity of flotation foam, complicated flotation process, low recovery rate, etc., and achieve reasonable utilization and solution The effect of low mineral processing technical indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

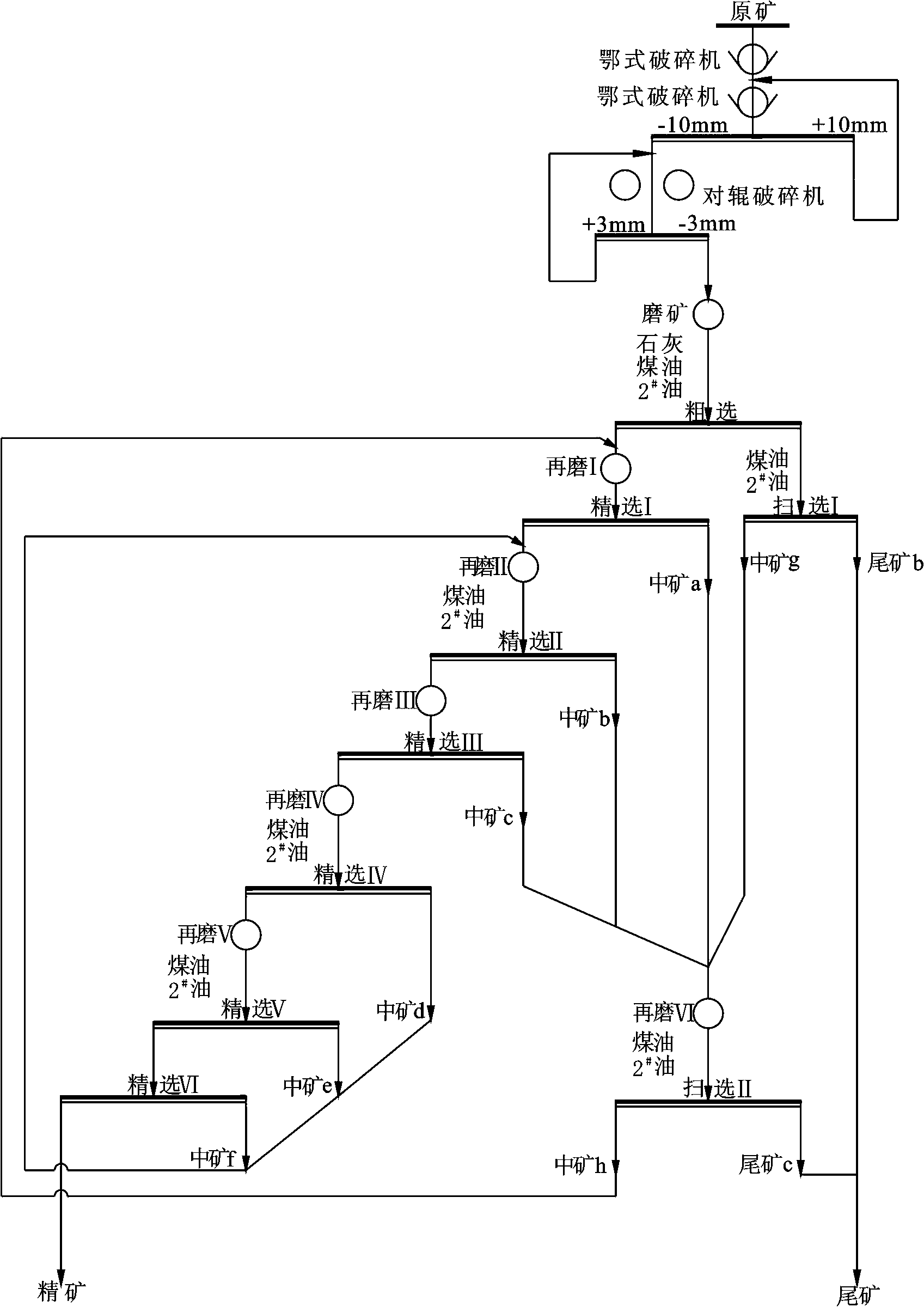

Method used

Image

Examples

Embodiment 1

[0024]A. Add the fine scale-aphanitic mixed graphite raw ore with a fixed carbon content of 20.55% into the jaw crusher, crush it to -3mm, and then grind the ore. The grinding concentration (mass concentration, the same below) is 65%. , the grinding time is 7min, the grinding fineness is -0.074mm, the content (mass content, the same below) is 90%, and the dissociation degree of graphite monomer is 75%; Add collector kerosene, foaming agent terpineol oil and regulator calcium oxide to the raw ore and stir for rough separation. The flotation concentration (mass concentration, the same below) is 20%, and the flotation time is 5 minutes to obtain a coarse concentrate. and tailings a; the formulation of the roughing agent is to add 550g of kerosene, 75g of terpineol oil and 1000g of calcium oxide in the raw ore of finely ground fine scale-aphanitic mixed graphite per ton;

[0025] B. Carry out regrinding to the coarse concentrate obtained in step A, the concentration of regrinding ...

Embodiment 2

[0031] Put the fine scale-aphanitic mixed graphite raw ore with a fixed carbon content of 25% into the roller crusher, crush it to -3mm, and then grind the ore. The grinding concentration is 65%, and the grinding time is 4min. The ore fineness is -0.074mm, the content is 91.11%, and the dissociation degree of graphite monomer is 70%. Add collector kerosene, foaming agent terpineol oil and Adjusting agent calcium oxide is stirred, and coarse selection is carried out, the flotation concentration is 20%, and the flotation time is 5 minutes to obtain coarse concentrate and tailings a; Add 820g of kerosene, 130g of terpineol oil and 1200g of calcium oxide in the graphite raw ore;

[0032] B. Carry out regrinding to the coarse concentrate obtained in step A, the concentration of regrinding is 22%, the time of regrinding is 6min, the grinding fineness is -0.045mm and the content is 92%, and then without adding any medicament In the case of regrinding, put the primary regrind product...

Embodiment 3

[0038] Add the fine scale-aphanitic mixed graphite raw ore with a fixed carbon content of 20% into the jaw crusher, crush it to -3mm, and then grind the ore. The grinding concentration is 65%, and the grinding time is 4min. The fineness is -0.074mm, the content is 95%, and the dissociation degree of graphite monomer is 68%. Add collector kerosene, foaming agent terpineol oil and adjust The flotation concentration is 20%, and the flotation time is 5 minutes, and the coarse concentrate and tailings a are obtained; the formulation of the roughing agent is a mixture of fine scales and aphaphanitic crystals per ton 900g of kerosene, 140g of terpineol oil and 1000g of calcium oxide were added to the graphite raw ore;

[0039]B. The rough concentrate obtained in step A is re-grinded once, the concentration of re-grinding is 30.81%, the time of re-grinding is 7.5min, the grinding fineness is -0.045mm and the content is 92.63%, and then without adding any In the case of chemicals, put...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com