Method for producing ammonium phosphate by utilizing low-grade low-concentration raffinate

A raffinate acid, low-concentration technology, applied in the direction of phosphate, phosphorus oxyacid, etc., can solve the problems of inability to continue the concentration operation, difficult cleaning, high environmental pressure and other problems, achieve economical utilization, reduce production costs, The effect of saving consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solutions in the embodiments of the present invention are clearly and completely described below in conjunction with the accompanying drawings.

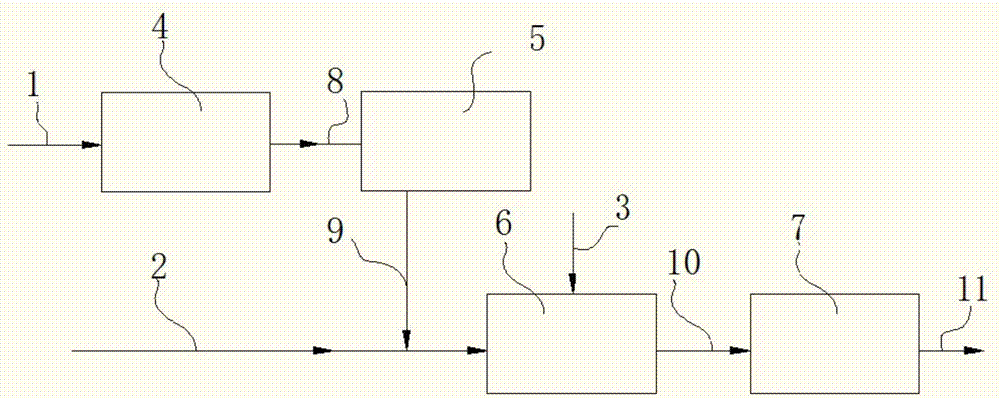

[0016] Such as figure 1 As shown, the by-product P of the wet process phosphoric acid purification plant 2 o 5 The low-grade and low-concentration raffinate 1 with a concentration of only about 23% is sent to the washing system 4 of the ammonium phosphate plant as a washing liquid to circulate and absorb ammonia and dust from the neutralization and granulation tail gas. When the degree of harmony is 0.6~0.9, it is sent to the concentration device 5 to be heated and concentrated to P 2 o 5 The concentration is 26%~30% concentrated slurry 9; then the concentrated slurry 9 is mixed with P from the phosphoric acid workshop 2 o 5 Concentrated phosphoric acid 2 with a concentration of 32% to 33% is mixed and then sent to neutralization reactor 6 to undergo neutralization reaction with gaseous ammonia 3. After the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com