Method for treating sulfureous bauxite

A technology of bauxite and ore pulp, which is applied in the direction of chemical instruments and methods, wet separation, solid separation, etc., can solve the problems of difficult dispersion of ore pulp, large amount of flotation reagents, and no flotation desilication operation, etc. Flotation desiliconization index, less dosage of flotation reagents, beneficial to the effect of backwater utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] As the best implementation mode of the present invention, it discloses a method for treating sulfur-containing bauxite. After the sulfur-containing bauxite is ground, the H in the pulp is increased and removed in the flotation desulfurization and desiliconization process flow. + , Fe 3+ , Fe 2+ The plasma process is beneficial to the dispersion of the pulp in the flotation desilication process, so that the useful aluminum minerals and aluminosilicates can be effectively separated; the extracted ones contain H + , Fe 3+ , Fe 2+Plasma clarified wastewater is used as a flocculant to flocculate alkaline products such as bauxite beneficiation concentrate, tailings or red mud, specifically:

[0030] After the sulfur-containing bauxite is ground, add and remove H in the pulp in the flotation desulfurization and desiliconization process + , Fe 3+ , Fe 2+ Plasma process. This process makes the H entering the flotation desilication pulp + , Fe 3+ , Fe 2+ Plasma is reduc...

Embodiment 2

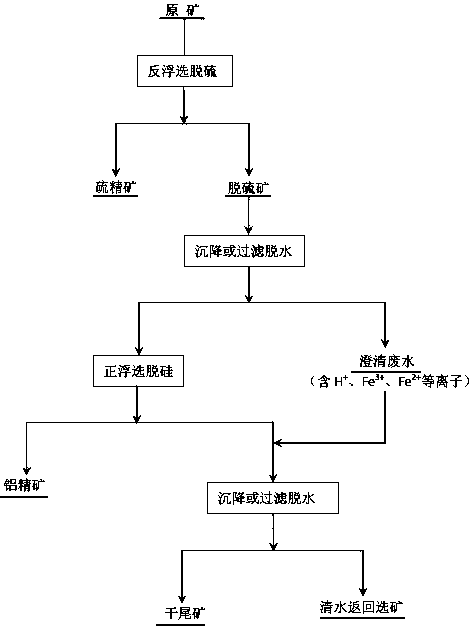

[0036] A low-grade sulfur-containing bauxite in Chongqing with an aluminum-silicon ratio of 4.7 and a sulfur content of 2.3% was used as a test sample. figure 1 The process flow shown is for flotation desulfurization and desiliconization of this low-grade sulfur-containing bauxite. Firstly, the ore is ground to a fineness of -0.075 mm, accounting for 75%, and butyl xanthate is added for reverse flotation desulfurization, and the desulfurized pulp is separated by sedimentation to obtain clarified wastewater and concentrated pulp; The process is positive flotation desiliconization to obtain aluminum concentrate and tailings; clarified wastewater is added to the tailings for flocculation and sedimentation, and dry tailings and backwater are obtained after separation.

[0037] The backwater is used in the closed-circuit test of mineral processing, and the test indicators are: the yield of aluminum concentrate is 68.0%, the aluminum-silicon ratio of aluminum concentrate is 9.1, and...

Embodiment 3

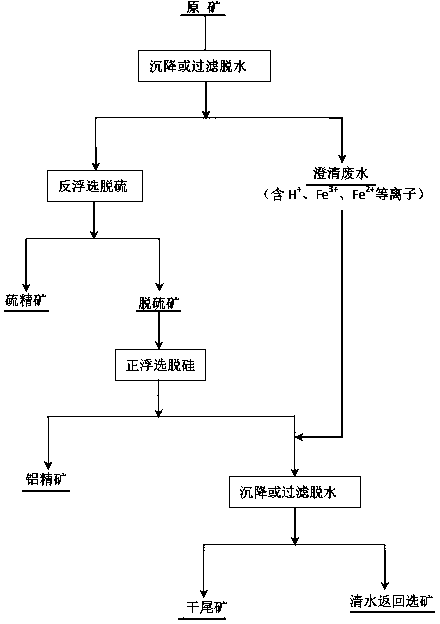

[0040] A low-grade sulfur-containing bauxite in Chongqing with an aluminum-silicon ratio of 4.7 and a sulfur content of 2.3% was used as a test sample. figure 2 The process flow shown is for flotation desulfurization and desiliconization of this low-grade sulfur-containing bauxite. Firstly, the ore is ground to a fineness of -0.075 mm, accounting for 75%, and the pulp is separated by sedimentation to obtain clarified wastewater and concentrated pulp; the thick pulp is added to xanthate for reverse flotation desulfurization, and the desulfurized pulp adopts a process of roughing, sweeping and refining Desiliconization by positive flotation to obtain aluminum concentrate and tailings; clarified wastewater is added to the tailings for flocculation and sedimentation, and dry tailings and backwater are obtained after separation.

[0041] The closed-circuit test of ore dressing uses backwater, and its test indicators are: the yield of aluminum concentrate is 64.7%, the aluminum-sil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com