Preparation method of SiC particle enhanced intermetallic compound based laminated composite material Ti/Al3Ti

A technology of intermetallic compounds and composite materials, which is applied in the field of preparation of particle-reinforced intermetallic compound-based composite materials, which can solve problems such as difficult control of layer spacing, layer thickness ratio, material performance adjustment and control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

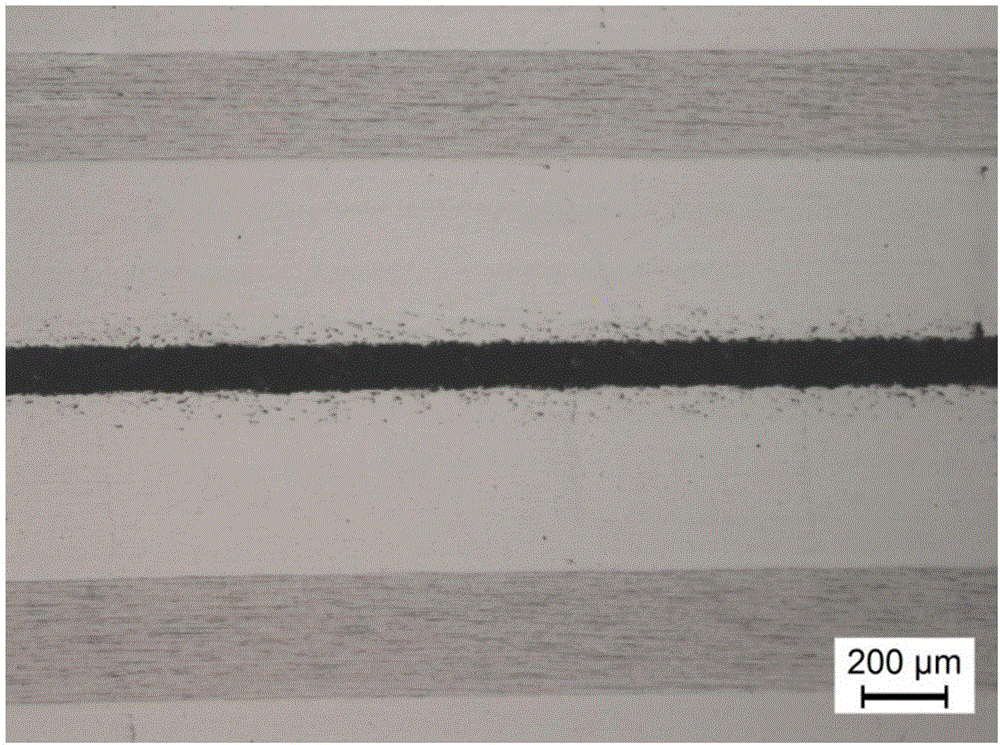

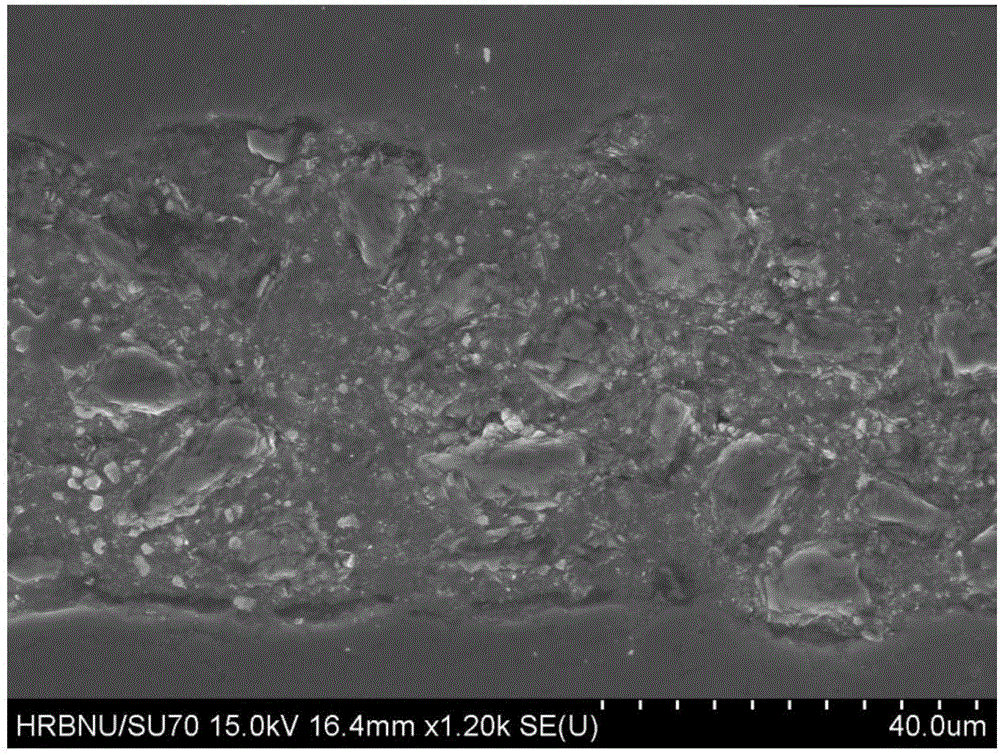

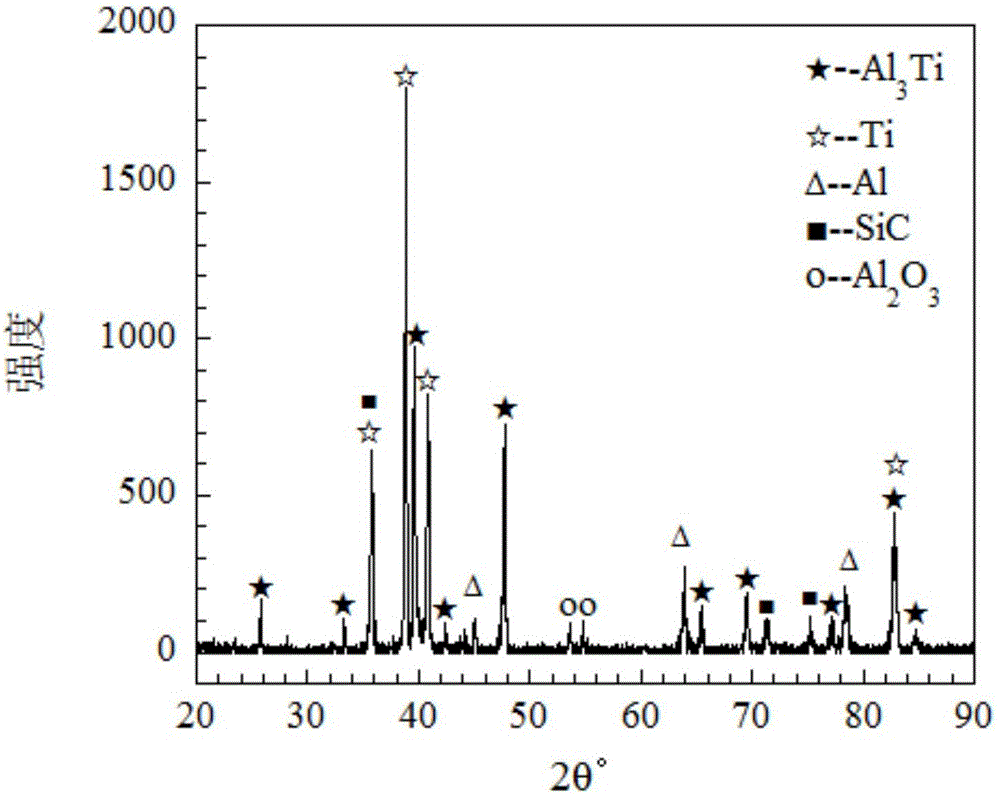

[0018] SiC-Ti / Al of the present invention 3 The new preparation method of Ti layered composite material includes: (1) selecting 1000 mesh (13 μm) Al powder with 99.7% purity, 1000 mesh (13 μm) SiC powder with 99.9% purity and TC4 alloy foil; (2) weighing Measure 100g of Al powder and SiC powder with a mass percentage of 1% to 3% of Al powder, add stearic acid with a mass percentage of 1% of Al powder as a dispersant, and ball mill in a high-energy ball mill to achieve a uniform mixing effect; (3) ball mill The final powder is added to the grinding tool and the SiC particle reinforced aluminum matrix composite material is prepared by powder metallurgy technology. The powder metallurgy process is to heat up to 350°C for 1h and hold for 1h, then heat up to 620°C for 2h and then cool with the furnace. From the beginning of heating, the pressure is always Keep it at 35.5-40MPa; (4) Hot-roll the SiC particle-reinforced aluminum-matrix composite material into a foil plate between 450...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| fracture strain | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com