Making method of integrally formed bicycle frame

A technology of integral forming and manufacturing method, applied in the direction of manufacturing tools, casting mold components, casting molding equipment, etc., can solve the problems of low safety, high scrap rate, poor body aesthetics, etc., to reduce the overall cost, save raw materials, The effect of improving quality and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

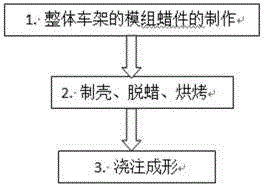

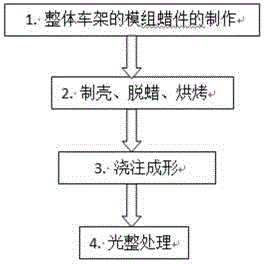

[0040] Example 1 as figure 1 , figure 2 , image 3 Shown, a kind of manufacturing method of integrally formed bicycle frame, its step comprises:

[0041] (1) Production of modular wax parts for the overall frame.

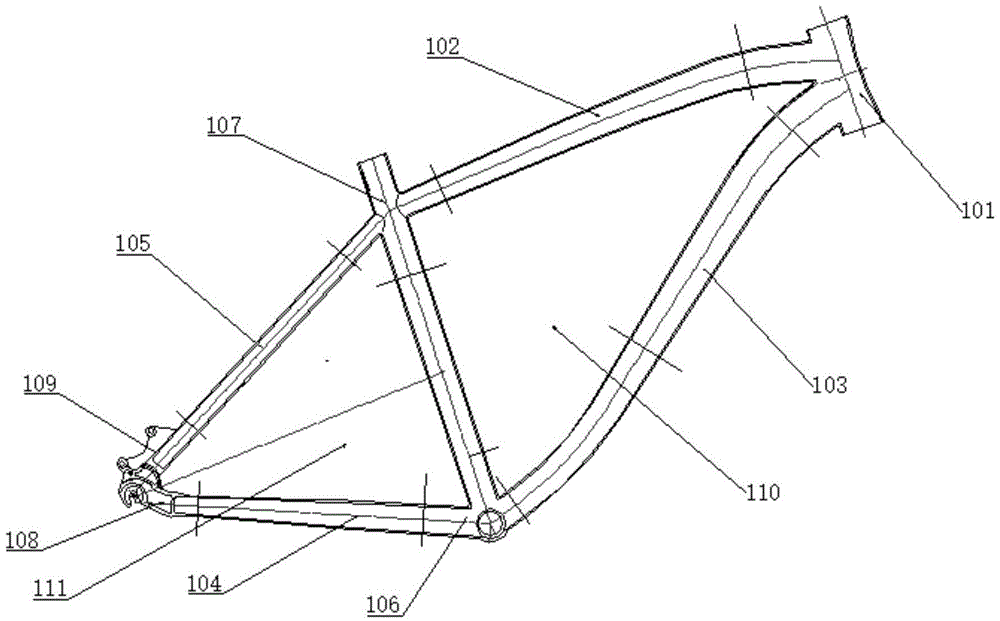

[0042] The module wax parts include vehicle frame wax parts and process wax parts, wherein the vehicle frame wax parts include front triangle wax parts 111 and rear triangle wax parts 112, first make the front triangle wax parts 111, assemble and weld the rear triangle wax parts 112, and then Make the craft wax piece, then weld the front triangle wax piece 111 and the craft wax piece to obtain a complete module wax piece.

[0043] Wherein, in step (1), the overall frame wax is welded by a frame wax component that can be conveniently press-injected to form an outer contour with a molding material, and form an inner cavity by pressing or a core. Described vehicle frame wax part is made up of five parts of front triangle wax part 111, left and right flat fork wax pa...

Embodiment 2

[0056] Example 2 as figure 1 , figure 2 , image 3 Shown, a kind of manufacturing method of integrally formed bicycle frame, its step comprises:

[0057] (1) Production of modular wax parts for the overall frame.

[0058] The module wax parts include vehicle frame wax parts and process wax parts, wherein the vehicle frame wax parts include front triangle wax parts 111 and rear triangle wax parts 112. The front triangle wax parts 111 are made first, and the rear triangle wax parts 112 are assembled. process wax piece, and then the front triangle wax piece 111 and the process wax piece are welded to obtain a complete module wax piece.

[0059] Wherein, in step (1), the overall frame wax is welded by a frame wax component that can be conveniently press-injected to form an outer contour with a mold material and form an inner cavity by a mold or a core. Described vehicle frame wax part is made up of five parts of front triangle wax part 111, left and right flat fork wax part 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com