Powder material of high temperature erosion resistant cladding layer and preparation method of cladding layer

A technology of powder material and cladding layer, applied in the field of preparation of powder material and cladding layer, can solve the problems of limited thickness of chromium plating, low life and reliability, corrosion, etc., achieve long life of cladding layer, improve cladding Efficiency and low cost of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

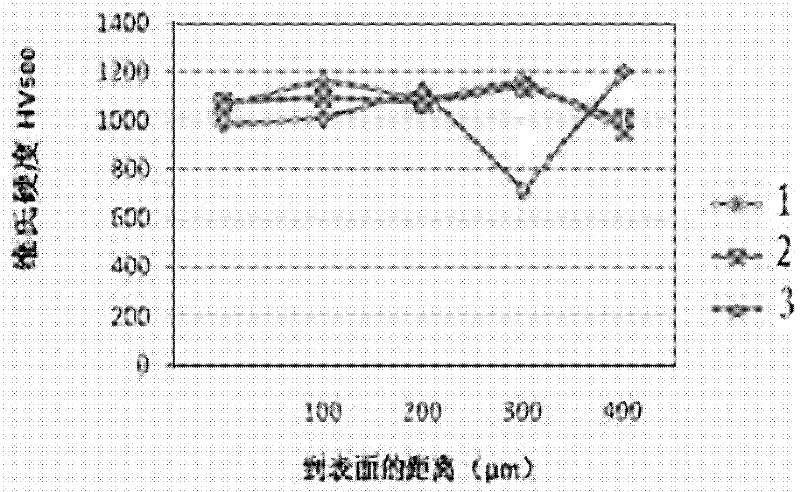

[0031] The preparation size is 500×400×3mm 3 The surface of the 16Mn steel plate was prepared with an average thickness of 400μm ceramic-metal composite cladding layer.

[0032] 1. Preparation of mixed powder raw materials

[0033] (1) The weight percent of powder material used for mixed powder is: pure titanium powder (particle size-250+300 mesh, purity ≥ 99.6%): 28wt.%; Graphite carbon powder: (purity ≥ 99.8%): 7wt.%; Chromium Powder (particle size-250+300 mesh, purity ≥99.8%): 28wt.%; molybdenum powder (particle size-250+300 mesh, purity ≥99.9%): 8wt.%; titanium diboride powder (particle size-250+300 Mesh, purity ≥99.8%): 4wt.%; Niobium carbide powder (particle size -250+300 mesh, purity ≥99.8%): 2wt.%; Nickel powder (particle size -250+300 mesh, purity ≥99.8%): Yu quantity.

[0034] (2) According to the various powder ratios described in step (1), take various powders required for powder raw materials;

[0035](3) Put the powder raw material into a drying oven for dryi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com