Nickel-iron spectrum standard sample and preparation method thereof

A spectroscopic standard sample, nickel-iron technology, applied in the field of nickel-iron standard sample and its preparation, can solve the problems of inconvenient measurement of nickel-iron spectrum, avoid the influence of sample composition and measurement, uniform chemical composition, and no graphite carbon precipitation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

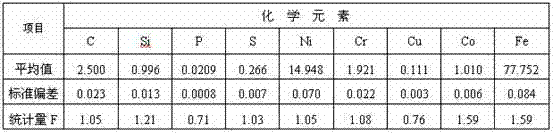

[0035] Embodiment 1: nickel-iron spectroscopic standard sample

[0036] The chemical elements uniformly contain the following weight percentages: Ni: 14.96±0.07%, C: 2.50±0.02%, Si: 1.04±0.02%, P: 0.020±0.001%; S: 0.28±0.01%, Co: 0.98±0.01 %, Cu: 0.12±0.01%, Cr: 1.94±0.02%, Fe: 77.85±0.09%, and the balance is impurities.

Embodiment 2

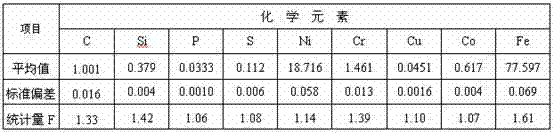

[0037] Embodiment 2: nickel-iron spectroscopic standard sample

[0038] The chemical elements uniformly contain the following weight percentages: Ni: 18.62±0.04%, C: 1.02±0.01%, Si: 0.39±0.01%, P: 0.0325±0.0005%; S: 0.113±0.006%, Co: 0.60±0.01 %, Cu: 0.049±0.001%, Cr: 1.49±0.02%, Fe: 77.66±0.05%, and the balance is impurities.

Embodiment 3

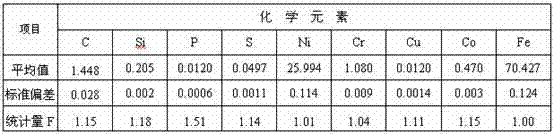

[0039] Embodiment 3: nickel-iron spectroscopic standard sample

[0040] Uniformly contains the following chemical elements by weight percentage: Ni: 25.95±0.08%, C: 1.45±0.01%, Si: 0.22±0.01%, P: 0.011±0.001%; S: 0.049±0.002%, Co: 0.46±0.01 %, Cu: 0.015±0.001%, Cr: 1.08±0.02%, Fe: 70.74±0.12%, and the balance is impurities.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com