Preparation process of high manganese steel based composite material

A preparation process and composite material technology, which is applied in the field of high manganese steel matrix composite material preparation process, can solve the problems of limited performance improvement of high manganese steel and inability to fully adapt to medium and low impact stress conditions, so as to avoid floating and segregation , good interface bonding effect, and the effect of improving wear life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Example 1: Making an integral composite material blanking liner

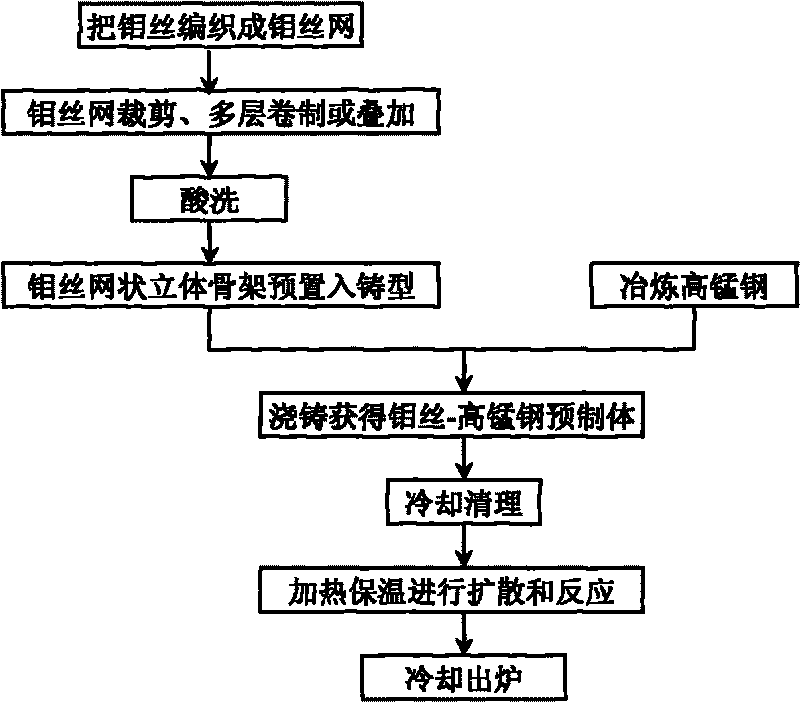

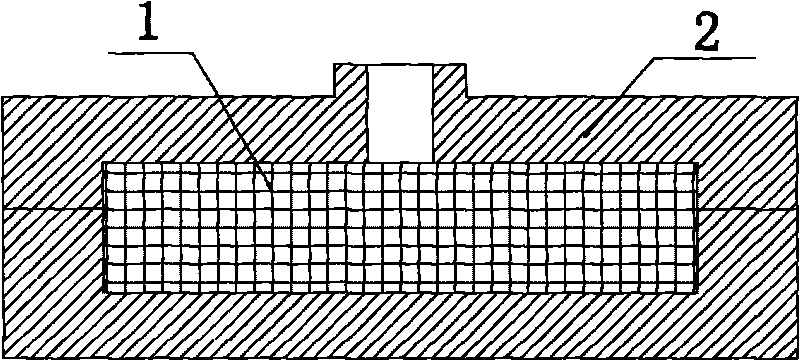

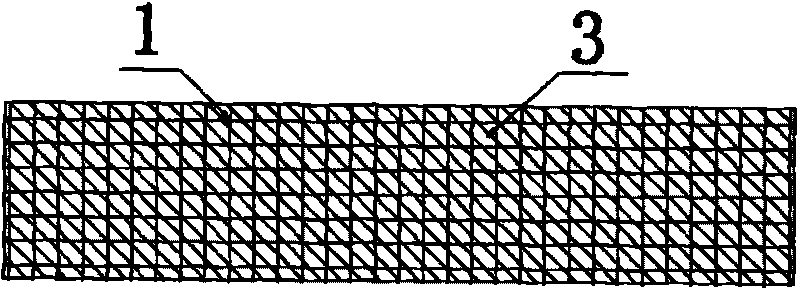

[0031] Such as figure 1 , figure 2 , image 3 with Figure 4 As shown, the specific operation steps are as follows:

[0032] (1) Woven molybdenum wire mesh 1 with 0.5mm molybdenum wire, and the molybdenum wire spacing is 2mm;

[0033] (2) Molybdenum wire mesh 1 is cut into a rectangle according to the length and height specifications of the blanking liner;

[0034] (3) pickling the rectangular molybdenum wire mesh 1;

[0035] (4) Make mold 2 according to casting process requirements;

[0036] (5) Overlay the cut molybdenum wire mesh 1 in multiple layers, and place it into the cavity of the water glass sand mold 2;

[0037] (6) Smelting high manganese steel 3 to obtain liquid high manganese steel;

[0038] (7) The liquid high manganese steel 3 is poured into the mold by adopting the gravity casting method, so that the liquid high manganese steel is filled with the voids of the net-like three-dimen...

Embodiment 2

[0042] Example 2: Making partial composite material blanking liner

[0043] Such as figure 1 with Figure 5 As shown, the specific operation steps are as follows:

[0044] (1) Woven molybdenum wire mesh 1 with 2.0mm molybdenum wire, and the molybdenum wire spacing is 10mm;

[0045] (2) Molybdenum wire mesh 1 is cut into a rectangle according to the length of the blanking liner and half the height specification;

[0046] (3) pickling the rectangular molybdenum wire mesh;

[0047] (4) Make mold 2 according to casting process requirements;

[0048] (5) Overlay the cut molybdenum wire mesh 1 in multiple layers, and place it into the cavity of the water glass sand mold 2;

[0049] (6) Smelting high manganese steel 3 to obtain liquid high manganese steel;

[0050] (7) The liquid high manganese steel 3 is poured into the mold by gravity casting to obtain a partial molybdenum wire-high manganese steel binary material preform;

[0051] (8) After cooling and stripping and cleanin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com