Preparation technology of vanadium carbide reinforced high manganese steel base composite material

A composite material and preparation process technology, which is applied in the field of preparation technology of vanadium carbide reinforced high-manganese steel-based composite materials, can solve the problems of not being able to fully adapt to medium and low impact stress conditions, and the performance improvement range of high-manganese steel is limited, and achieves good performance. Interface bonding effect, avoid floating and segregation, improve wear life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Example 1: Making an integral composite material blanking liner

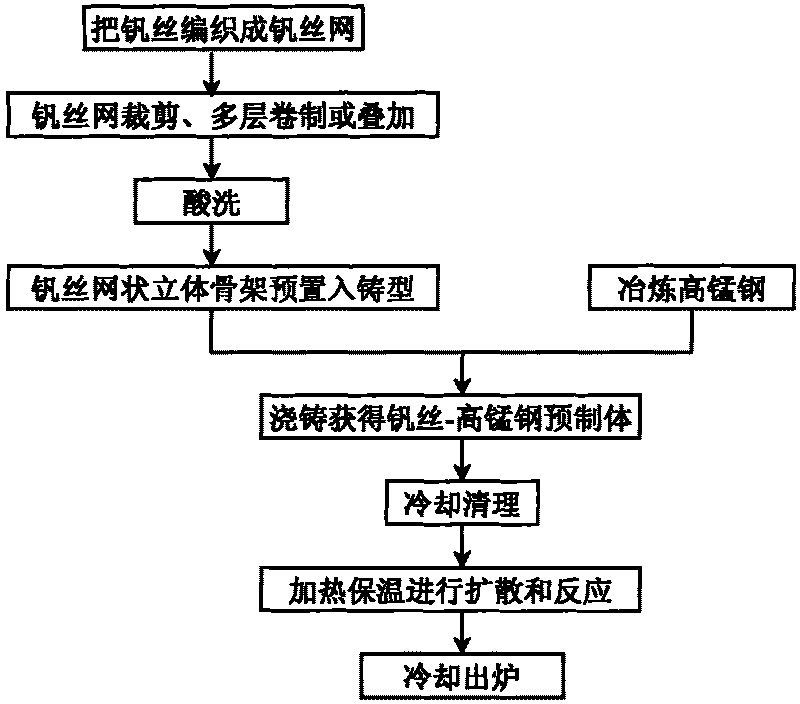

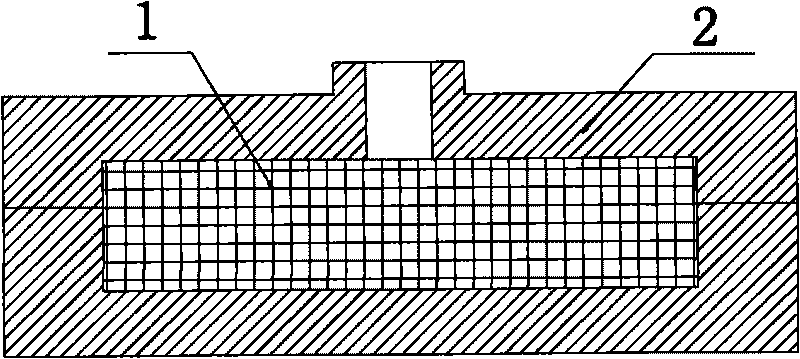

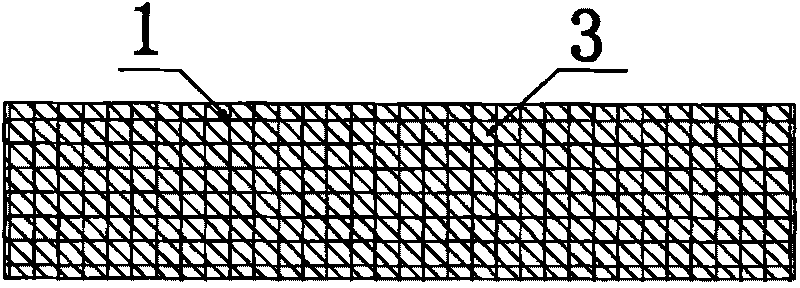

[0031] like figure 1 , figure 2 , image 3 and Figure 4 As shown, the specific operation steps are as follows:

[0032] (1) weaving vanadium wire mesh 1 with 0.5mm vanadium wire, the vanadium wire spacing is 2mm;

[0033] (2) Vanadium wire mesh 1 is cut into a rectangle according to the length and height specifications of the blanking liner;

[0034] (3) pickling the rectangular vanadium wire mesh 1;

[0035] (4) Make mold 2 according to casting process requirements;

[0036] (5) stack the vanadium wire mesh 1 multilayer that has been cut, and place it into the mold cavity of the water glass sand mold 2;

[0037] (6) Smelting high manganese steel 3 to obtain liquid high manganese steel;

[0038] (7) The liquid high manganese steel 3 is poured into the mold by adopting the gravity casting method, so that the liquid high manganese steel is filled with the voids of the net-like three-dimensional sk...

Embodiment 2

[0042] Example 2: Making partial composite material blanking liner

[0043] like figure 1 and Figure 5 As shown, the specific operation steps are as follows:

[0044] (1) Weave vanadium wire mesh 1 with 2.0mm vanadium wire, and the vanadium wire spacing is 10mm;

[0045] (2) Vanadium wire mesh 1 is cut into a rectangle according to the length of the blanking liner and half the height specification;

[0046] (3) pickling the rectangular vanadium wire mesh 1;

[0047] (4) Make mold 2 according to casting process requirements;

[0048] (5) Overlay the cut vanadium wire mesh 1 in multiple layers, and place it into the cavity of the water glass sand mold 2;

[0049] (6) Smelting high manganese steel 3 to obtain liquid high manganese steel;

[0050] (7) The liquid high manganese steel 3 is poured into the mold by gravity casting method to obtain a partial vanadium wire-high manganese steel binary material prefabricated body;

[0051] (8) After cooling and stripping and clean...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com