Preparation technology of vanadium carbide reinforced nodular cast iron base composite material

A technology of ductile cast iron and composite materials, which is applied in the field of preparation technology of vanadium carbide reinforced ductile iron-based composite materials, which can solve the problems of difficult stable control of the preparation process, difficulty in obtaining wear-resistant ductile iron, uneven distribution of reinforced particles, etc., and achieves a good interface Combining effects, avoiding strengthening phase interface weakening problems, avoiding effects of floating and segregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1: Making an integral composite material blanking liner

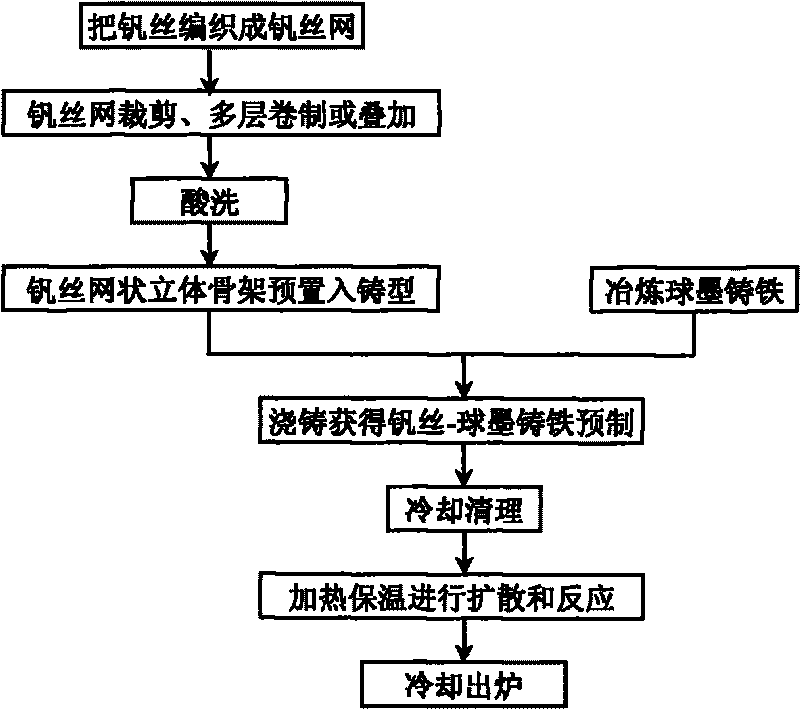

[0030] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the specific operation steps are as follows:

[0031] (1) weaving vanadium wire mesh 1 with 0.5mm vanadium wire, the vanadium wire spacing is 2mm;

[0032] (2) Vanadium wire mesh 1 is cut into a rectangle according to the length and height specifications of the blanking liner;

[0033] (3) pickling the rectangular vanadium wire mesh 1;

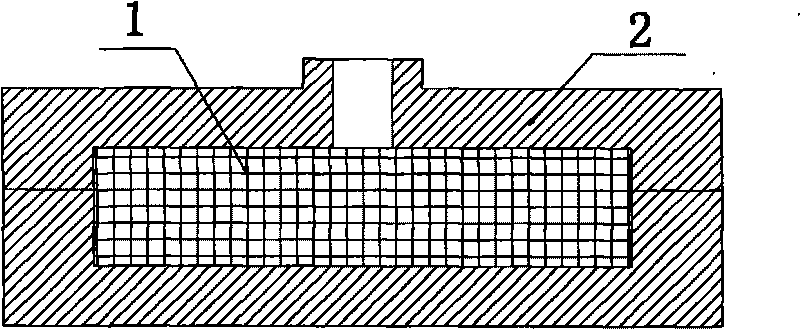

[0034] (4) Make mold 2 according to casting process requirements;

[0035] (5) stack the vanadium wire mesh 1 multilayer that has been cut, and place it into the mold cavity of the water glass sand mold 2;

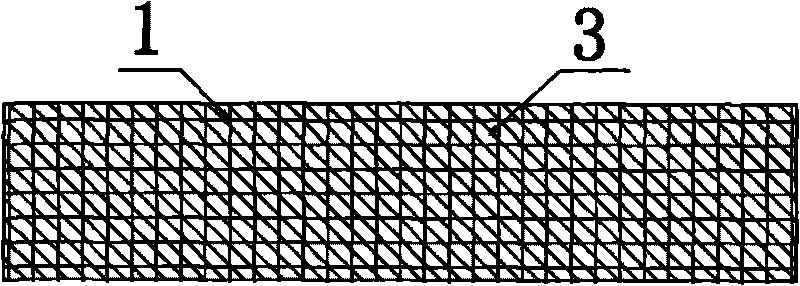

[0036] (6) smelting ductile iron 3 to obtain liquid ductile iron;

[0037] (7) The liquid ductile iron 3 is poured into the mold by adopting the gravity casting method, so that the liquid ductile iron is filled with the voids of the net-like three-dimensional skeleton, and the vanadium wire...

Embodiment 2

[0041] Example 2: Making partial composite material blanking liner

[0042] Such as figure 1 and Figure 5 As shown, the specific operation steps are as follows:

[0043] (1) Weave vanadium wire mesh 1 with 2.0mm vanadium wire, and the vanadium wire spacing is 10mm;

[0044] (2) Vanadium wire mesh 1 is cut into a rectangle according to the length of the blanking liner and half the height specification;

[0045] (3) Pickling the rectangular vanadium wire mesh;

[0046] (4) Make mold 2 according to casting process requirements;

[0047] (5) stack the vanadium wire mesh 1 multilayer that has been cut, and place it into the mold cavity of the water glass sand mold 2;

[0048] (6) smelting ductile iron 3 to obtain liquid ductile iron;

[0049] (7) The liquid ductile iron 3 is poured into the mold by a gravity casting method to obtain a partial vanadium wire-ductile iron binary material preform;

[0050] (8) After cooling and stripping and cleaning, put the local vanadium wir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com