Carbon nitride photocatalytic activity nano fiber membrane and preparation method thereof

A nanofiber membrane, catalytic activity technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve problems that have not been reported yet, achieve strong visible light absorption, large specific surface area, The effect of high practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

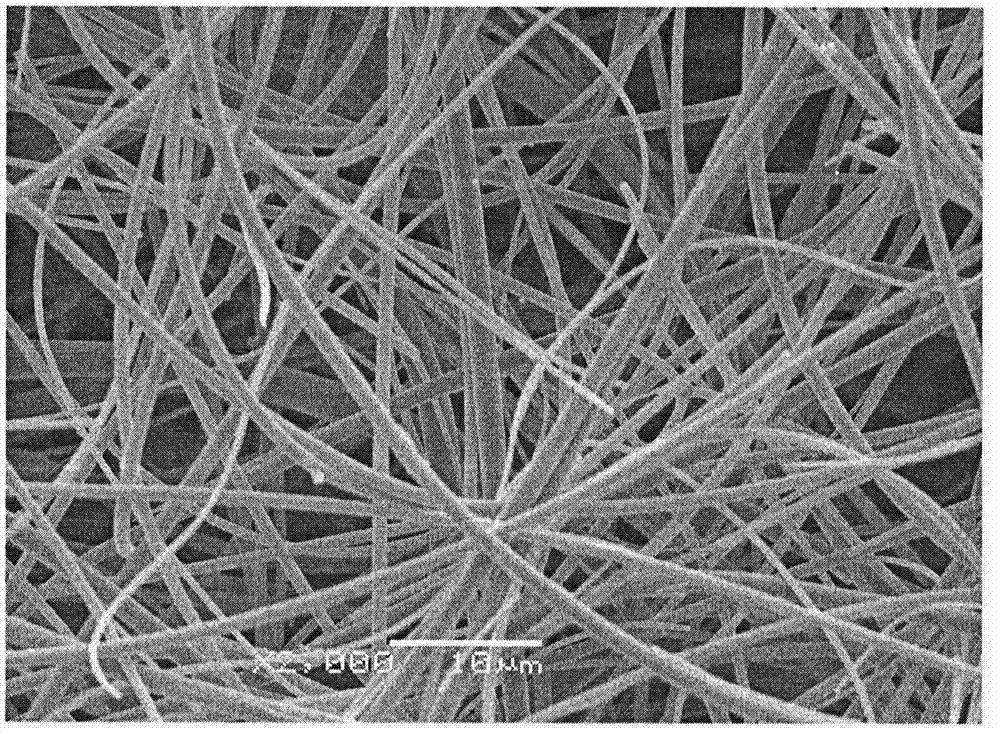

[0026] Weigh 2g of polypyrazinamide, dissolve it in 10g of dichloromethane, stir at room temperature until it is completely dissolved, and keep it at 5°C for 12 hours to ripen polyazinamide so that its polymer chains are fully expanded in the solution to form a spinnable Spinning solution with good properties, add 5 drops of trifluoroacetic acid dropwise during spinning to improve the conductivity of spinning solution, place the high-voltage electrospinning device in a closed system, and remove the oxygen in the system with magnesium powder in advance to reach the mass concentration Less than 1% and heat the receiving screen to 550°C, add the above spinning solution to the spinning head, adjust the spinning head to 15cm away from the receiving screen, apply the electric field voltage to 50 kV, start spinning, and spin for 10 minutes , slowly reduce the surface temperature of the receiving screen at a rate of 5°C / min, anneal the carbon nitride fiber until the receiving screen dr...

no. 2 example

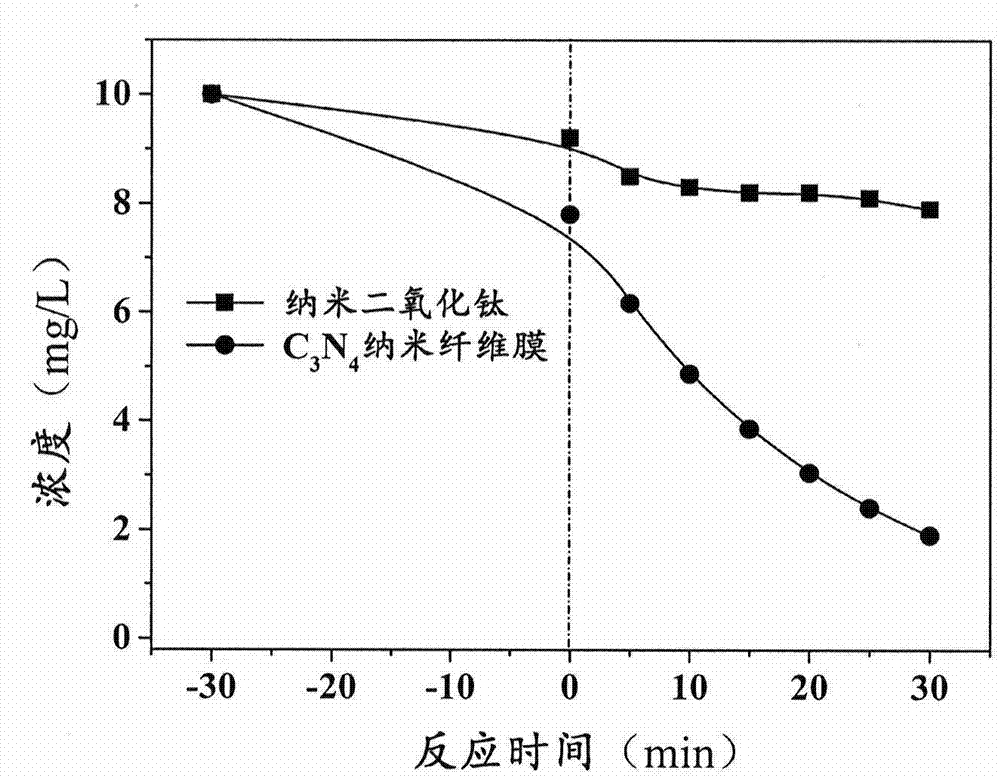

[0029] The second embodiment is a modified example of the first embodiment, using 2 g of 1,3,5-polytriazine aromatic amide, dissolving it in 24 g of dichloromethane, adding 5 drops of trifluoroacetic acid dropwise during spinning, and using aluminum powder Deoxidation, electrospinning electrode spacing 10cm, applied voltage 40kV, after spinning for 15 minutes, the temperature of the receiving screen was lowered at 2°C / min, and the rest of the conditions were the same as those of the first embodiment, and will not be repeated here. Treat pentachlorophenol (10mg / L) in water with this fiber membrane, and removal rate is 83.2% in 30 minutes (see attachment figure 2 ).

no. 3 example

[0031]The second embodiment is a modified example of the first embodiment. 1.5 g of polybenzoxazine is used, dissolved in 12 g of methylene chloride, and 4 drops of trifluorobutyric acid are added dropwise during the spinning process, deoxidized with zinc powder, and electrospun The distance between the wire plates is 12.5 cm, the applied voltage is 30 kV, and after 12 minutes of spinning, the temperature of the receiving screen is lowered at 3.5° C. / min, and other conditions are the same as those of the first embodiment. The fiber membrane was used to treat chloroform (5.0 mg / L) in water, and the removal rate was 99.7% in 2 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com