Integral honeycomb molecular sieve for purifying VOCs in zeolite adsorption runner and preparation

A molecular sieve, integrated technology, applied in the field of inorganic materials for VOCs purification, can solve the problems of easy cracks on the surface of the honeycomb body, cracked molecular sieve content, large mass transfer resistance, etc., to achieve high VOCs removal rate and penetration adsorption capacity, Fast adsorption and desorption rates, improved plasticity and rheology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

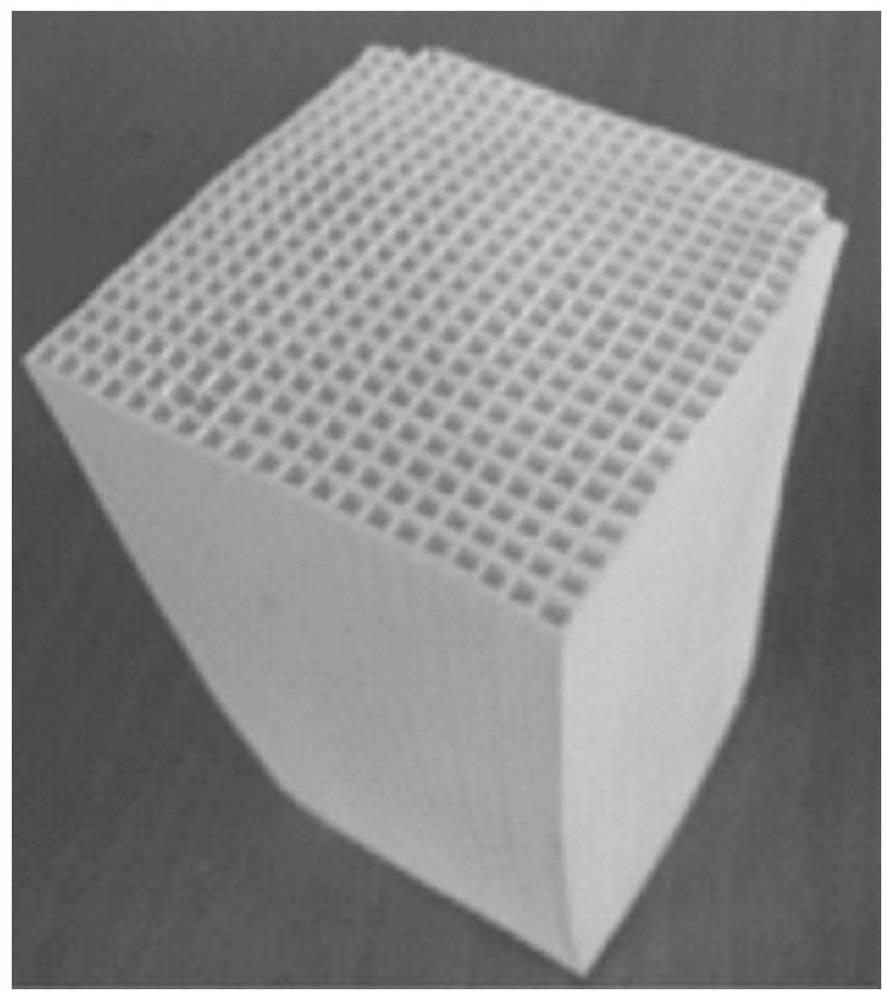

[0042]A preparation method of integrally extruded honeycomb molecular sieve suitable for purification of VOCs by zeolite adsorption rotor, adopts the following steps:

[0043]Step 1: Weigh 720g of ZSM-5 molecular sieve powder with a silicon-to-aluminum ratio of 300, 400g of Y molecular sieve powder with a silicon-to-aluminum ratio of 100, 80g of β molecular sieve powder with a silicon-to-aluminum ratio of 40, 149g of calcined kaolin, and 132g of aluminum sol (to oxidize It is adjusted to a solid content of 10 wt% by adding water, and pre-granulation after sufficient stirring. The pre-granulation conditions are: inlet air temperature 280°C, outlet air temperature 160°C. Then, the powder obtained after pre-granulation is calcined at 550° C. for 6 hours, and sieved to obtain fine particles with a particle size of 0.03-0.05 mm.

[0044]Step 2: First, weigh 864g of particulate powder, 96g of E-glass fiber, 48g of methyl cellulose, 36g of starch, 12g of polyethylene oxide and 6g of sodium stear...

Embodiment 2

[0051]A preparation method of integrally extruded honeycomb molecular sieve suitable for purification of VOCs by zeolite adsorption rotor, adopts the following steps:

[0052]Step 1: Weigh 1200g of the original ZSM-5 molecular sieve powder with a silicon-to-aluminum ratio of 300, 149g calcium silicate, and 132g silica sol (calculated as oxide), and add water to adjust to a solid content of 40wt%, and pre-granulate after fully stirring , The pre-granulation conditions are: the inlet air temperature is 220°C, and the outlet air temperature is 100°C. Then, the powder obtained after pre-granulation is calcined at 850° C. for 2 hours, and sieved to obtain fine particles with a particle size of 0.03-0.05 mm.

[0053]Step 2: First, weigh 864g particulate powder, 96g E-glass fiber, 48g hydroxypropyl methylcellulose, 36g starch, 12g polyethylene oxide and 6g sodium stearate and mix in a high-speed mixer for 1h . Then, move the uniformly mixed powder into the kneader, add 6g glycerol, 240g silica s...

Embodiment 3

[0059]A preparation method of integrally extruded honeycomb molecular sieve suitable for purification of VOCs by zeolite adsorption rotor, adopts the following steps:

[0060]Step 1: Weigh 800g of ZSM-5 molecular sieve powder with a silicon-to-aluminum ratio of 300, 400g of Y molecular sieve powder with a silicon-to-aluminum ratio of 60, 149g cordierite, and 132g aluminum sol (calculated as oxide), and add water to adjust to the solid content It is 20wt%, and it is pre-granulated after being fully stirred. The pre-granulation conditions are: the inlet air temperature is 240°C, and the outlet air temperature is 120°C. Then, the powder obtained after pre-granulation is calcined at 850° C. for 3 hours, and sieved to obtain fine particles with a particle size of 0.03-0.05 mm.

[0061]Step 2: First, weigh 864g of microparticle powder, 96g of E-glass fiber, 48g of carboxymethyl cellulose, 36g of starch, 12g of polyethylene oxide and 6g of calcium stearate and mix them in a high-speed mixer for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com