Novel pulverized coal pyrolytic hydrogenation reactor and pyrolytic hydrogenation reaction method

A hydrogenation reactor and a hydrogenation reaction technology are applied in the petroleum industry, the preparation of liquid hydrocarbon mixtures, etc., and can solve the problems of the reaction condition requirements of the polluted coal-to-liquid method, the low utilization rate of heat energy recovery, and the low utilization rate of raw materials, etc. Achieve the effect of lower material requirements, lower cost investment, and shorter response time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

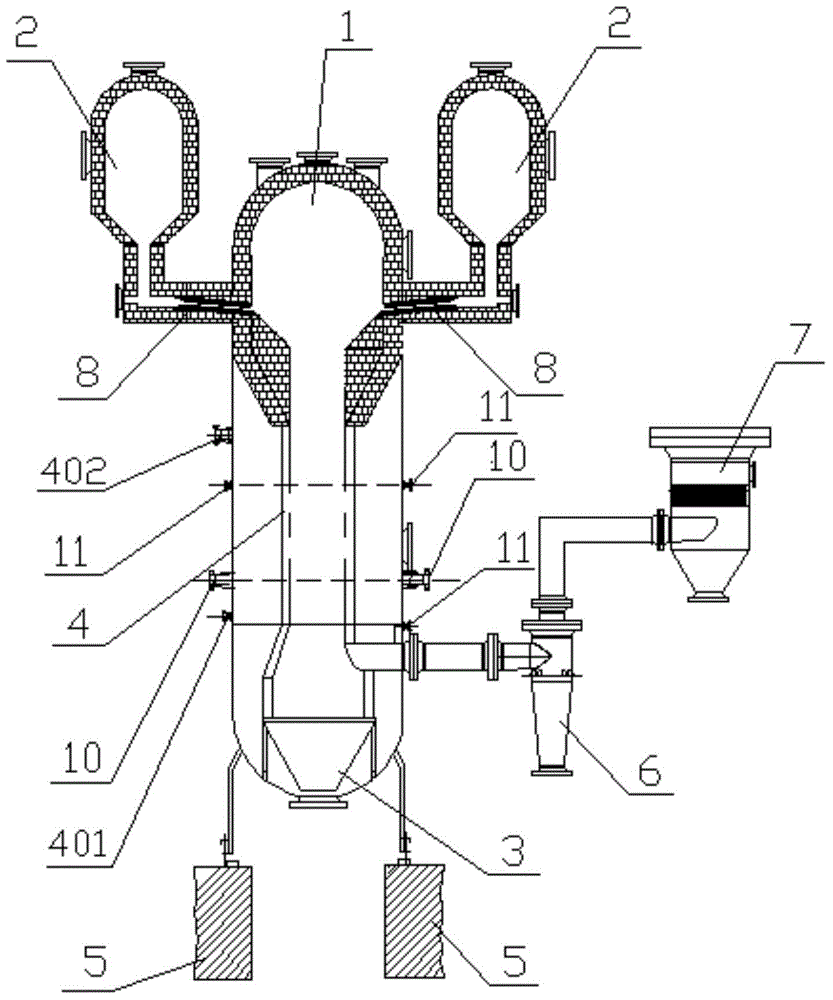

[0027] Such as figure 1 As shown, a novel pulverized coal pyrolysis hydrogenation reactor in the present embodiment includes a reaction chamber 1 provided with pulverized coal nozzles, 2 converter furnaces 2 provided with process burners, 2 synthesis gas nozzles 8, Quenching chamber 4, primary separator 3, two constant force cranes 5, secondary separator 6 and tertiary separator 7, the two converter furnaces 2 are symmetrically arranged on both sides of the reaction chamber 1, and the converter furnace 2 The gas outlet of the synthetic gas nozzle 8 is connected with the air inlet of the synthesis gas nozzle 8, and the gas outlet of the synthesis gas nozzle 8 is connected with the air inlet arranged at the middle part of the side wall of the reaction chamber 1, and the axis of the synthesis gas nozzle 8 is connected with the reaction chamber 1 air intake. The included angle of the horizontal line of the mouth is 15 degrees, and the reaction chamber 1 is arranged on the top of t...

Embodiment 2

[0035] The novel pulverized coal pyrolysis hydrogenation reactor in this example is the same as the novel pulverized coal pyrolysis hydrogenation reactor in Example 1.

[0036] A method of using the novel pulverized coal pyrolysis hydrogenation reactor described in this embodiment to carry out pulverized coal pyrolysis hydrogenation reaction comprises the following steps:

[0037] 1) The raw coal is sent to the grinding and drying system to produce coal powder with a particle size of less than 90 microns, a moisture content of less than 3%, and a temperature of 100-105°C;

[0038] 2) The mixed gas composed of natural gas and oxygen is sent to the conversion furnace (2) through the process burner for combustion, and a high-temperature gas of 1600°C is produced and mixed with hydrogen entering the conversion furnace (2) through the hydrogen port to form a temperature of 1400°C The mixed gas is sent into the reaction chamber (1) as a pyrolysis source, and the mixed gas pressure i...

Embodiment 3

[0043] The novel pulverized coal pyrolysis hydrogenation reactor in this example is the same as the novel pulverized coal pyrolysis hydrogenation reactor in Example 1.

[0044] A method of using the novel pulverized coal pyrolysis hydrogenation reactor described in this embodiment to carry out pulverized coal pyrolysis hydrogenation reaction comprises the following steps:

[0045] 1) The raw coal is sent to the grinding and drying system to produce coal powder with a particle size of less than 90 microns, a moisture content of less than 3%, and a temperature of 100-105°C;

[0046] 2) The mixed gas composed of natural gas and oxygen is sent to the conversion furnace (2) through the process burner for combustion, and a high-temperature gas of 1500 ° C is produced and mixed with hydrogen entering the conversion furnace (2) through the hydrogen port to form a temperature of 1300 ° C The mixed gas is sent into the reaction chamber (1) as a pyrolysis source, and the mixed gas pressu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com