Patents

Literature

37results about How to "High degree of cleanliness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Environment-friendly type crust leather production method

ActiveCN103060488AEmission reductionCreate pollutionTanning treatmentPre-tanning chemical treatmentChromiumIon

The invention discloses an environment-friendly type crust leather production method, and aims at solving the problems that in a crust leather production method using conventional chrome tanning as basis, plenty of chromium ions are contained in waste water and cannot be effectively processed, plenty of leather wastes with chrome are also generated, and the environment is seriously polluted. The production method comprises the following steps of non-pickling tanning, retanning filling, dyeing fat liquoring and chrome retanning. The method adopts non-pickling non-chrome tanning technology, so solid wastes with the chrome cannot be generated. At the same time, through mutual matching with other procedures, finished leather shrinkage temperature and performance can be effectively improved so as to meet demands of leather production. At the last, the chrome retanning is adopted, only a path of waste water with the chrome is generated, waste water quantity is small, and the waste water is easy to recover and process. Therefore, compared with an existing crust leather production method using a chrome tanning method as basis, cleaning degree is high, the waste water quantity with the chrome can be effectively reduced, and the waste water is convenient to recover and process. At the same time, the leather wastes with the chrome cannot be produced, and the method is environment-friendly.

Owner:四川亭江新材料股份有限公司 +1

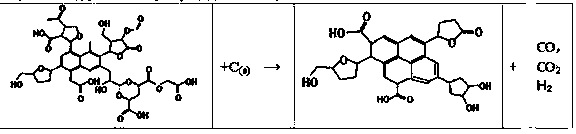

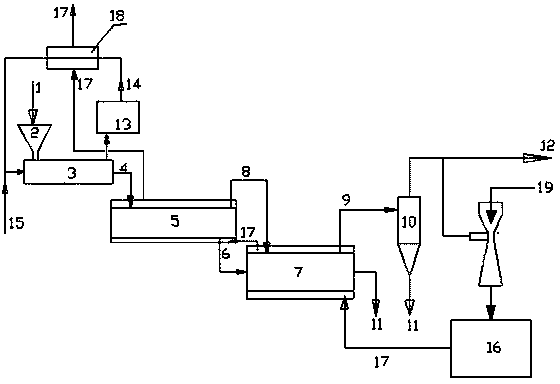

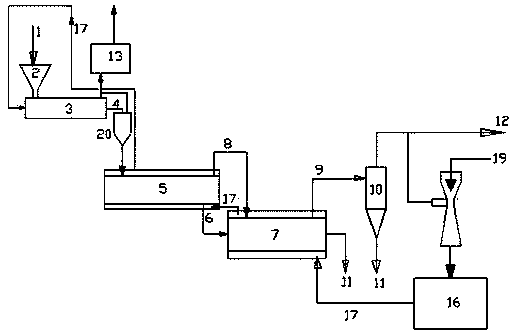

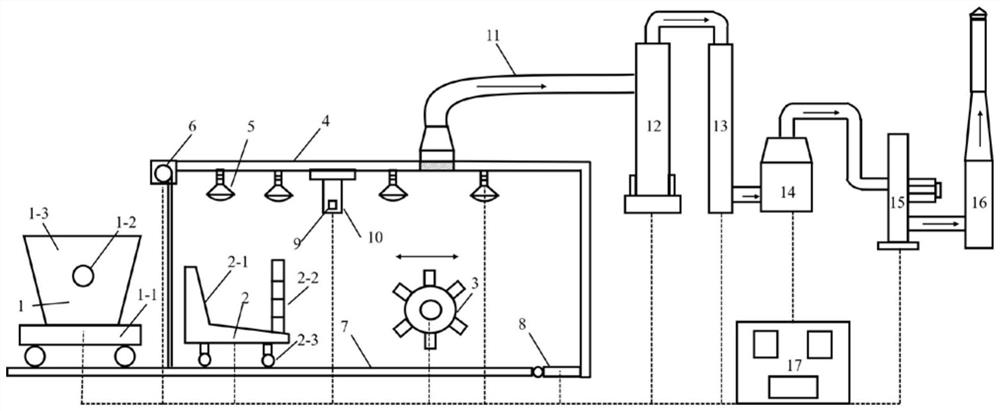

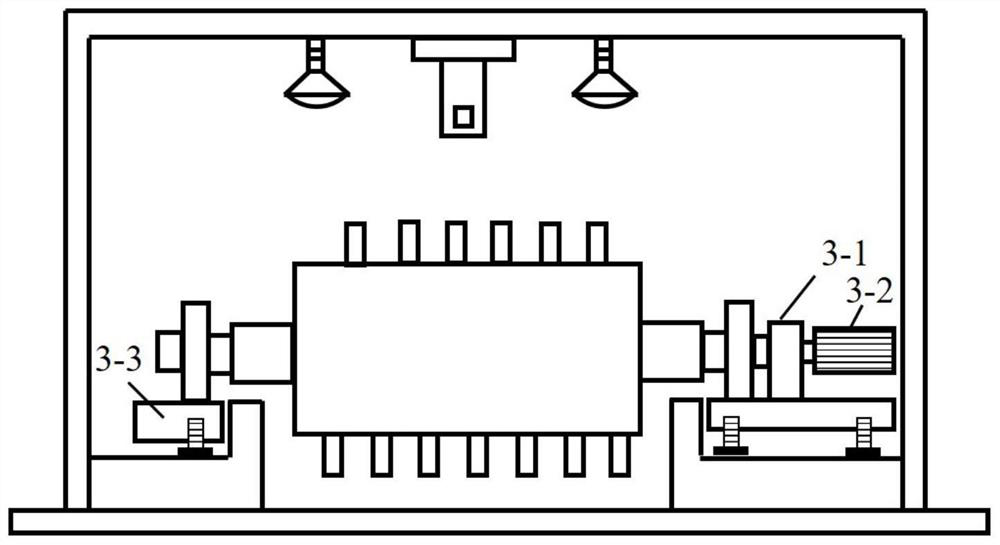

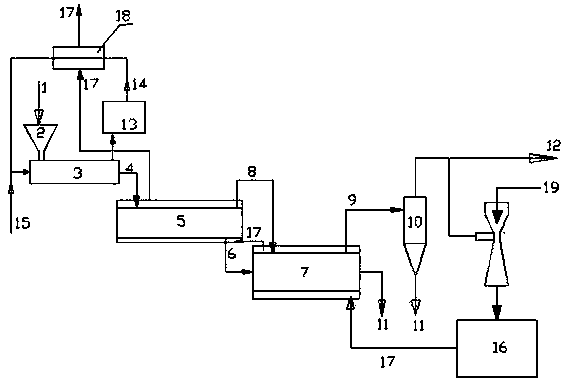

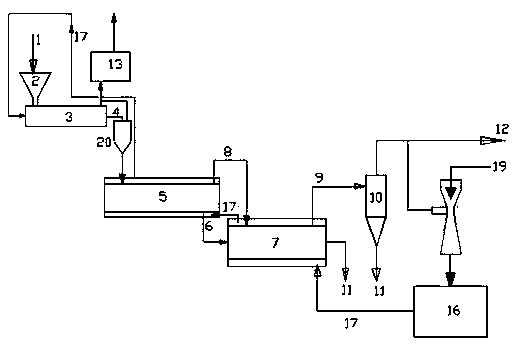

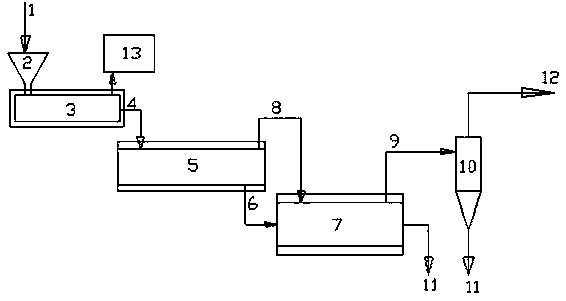

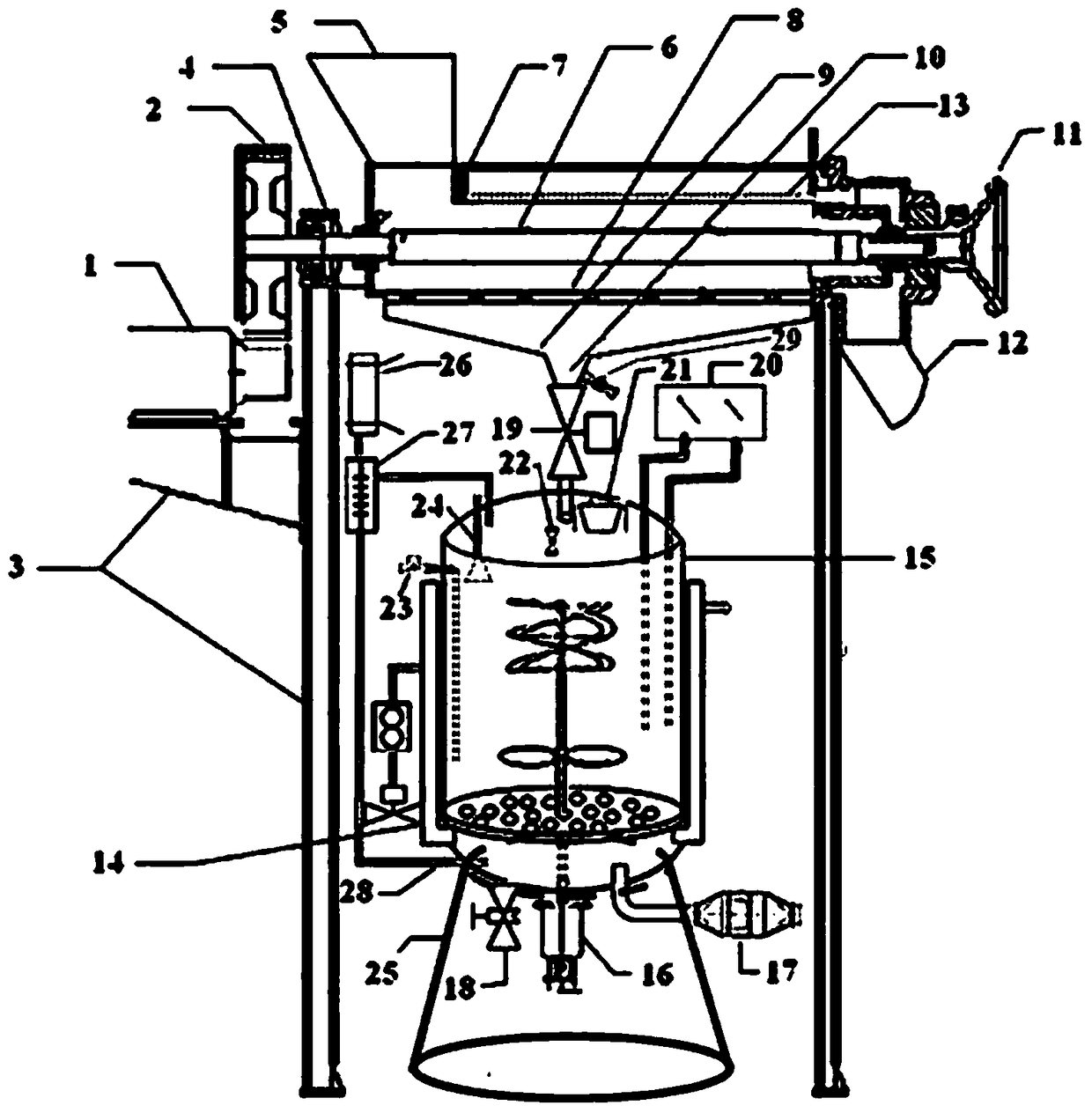

Waste pyrolysis system with adjustable oil, gas and carbon and method

ActiveCN104087340ALightweightLow viscositySolid waste disposalSludge treatment by pyrolysisThermodynamicsFlue gas

The invention relates to a waste pyrolysis system with adjustable oil, gas and carbon and a method. The system comprises a pre-reaction section, a main reactor, a conditioner and a particle separator. The front of the pre-reaction section is connected to a feeder and the tail of the pre-reaction section is connected to the main reactor. The conditioner is connected after the main reactor. The particle separator is connected after the conditioner. In specific, waste having a water content not more than 60% is fed into the pre-reaction section through the feeder, reacted waste is fed to the main reactor, residue coke generated after the reaction is finished is fed into the conditioner and a generated volatile material is discharged in a forced manner into the conditioner to be contacted, reacted and conditioned with the residue coke at the same time. The conditioner achieves conditioning of the residue coke and the volatile material at the same time. The volatile material after being conditioned is fed into the particle separator to output a clean volatile material. The residue coke after conditioning has a calorific value of 3.37-6.74 MJ / kg, and can be used as building raw materials or is conveyed to a sanitary landfill. The working temperature of the pre-reaction section is 105-298 DEG C and an inert gas or flue gas is fed into the pre-reaction section. The working temperature of the main reactor is 450-650 DEG C. The working temperature of the conditioner is 700-900 DEG C. The system and the method can obtain oil with better quality and more combustible gases and are adapt to changes of the water content of the waste.

Owner:上海济德能源环保技术有限公司

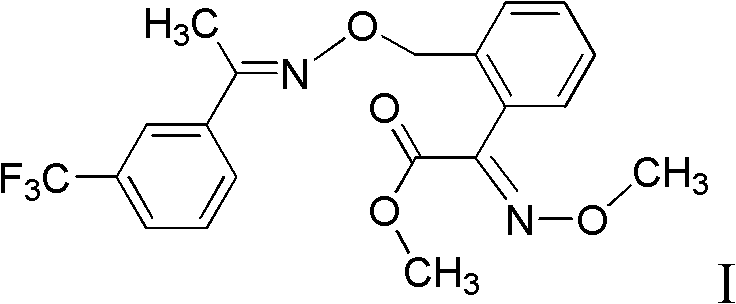

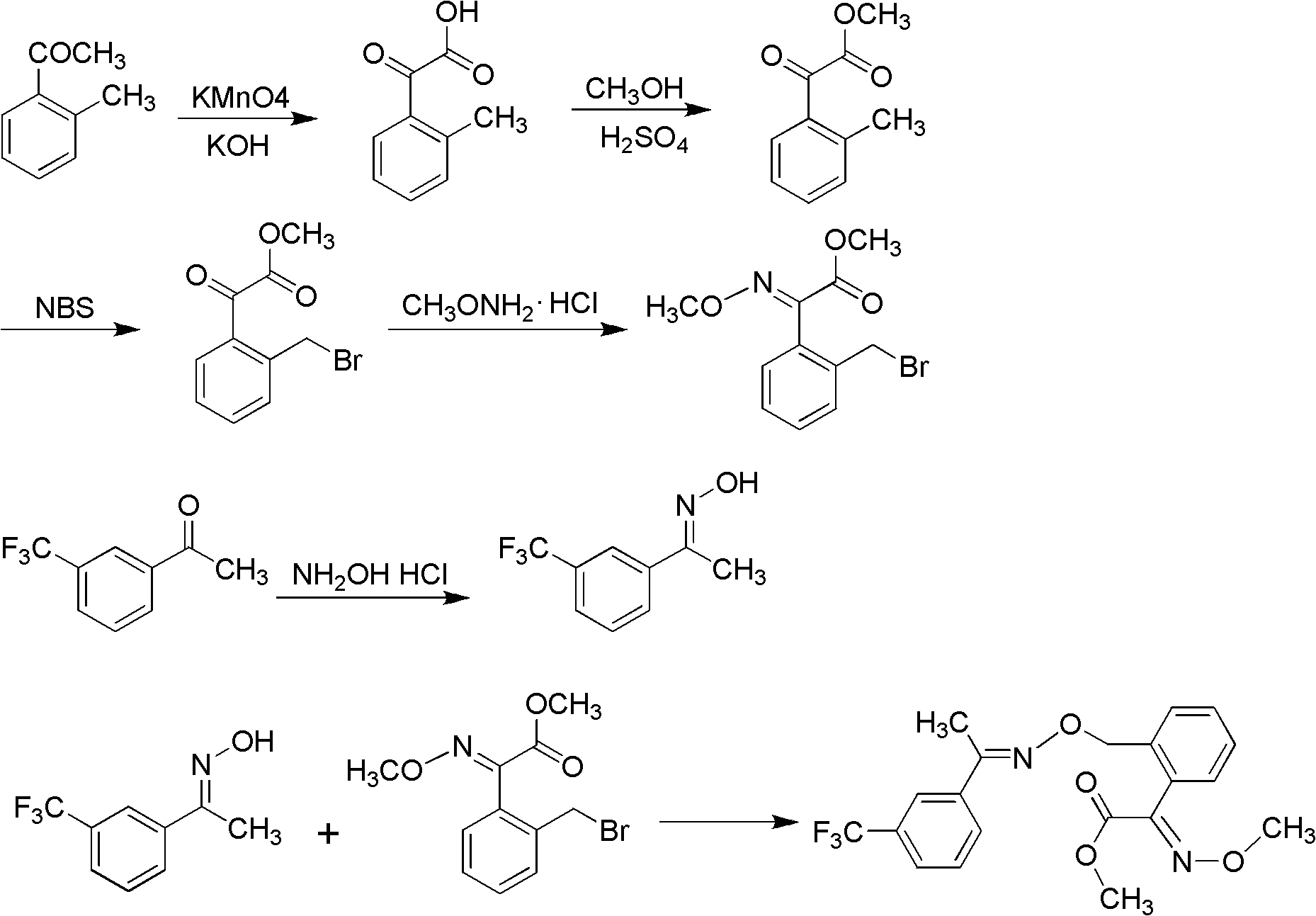

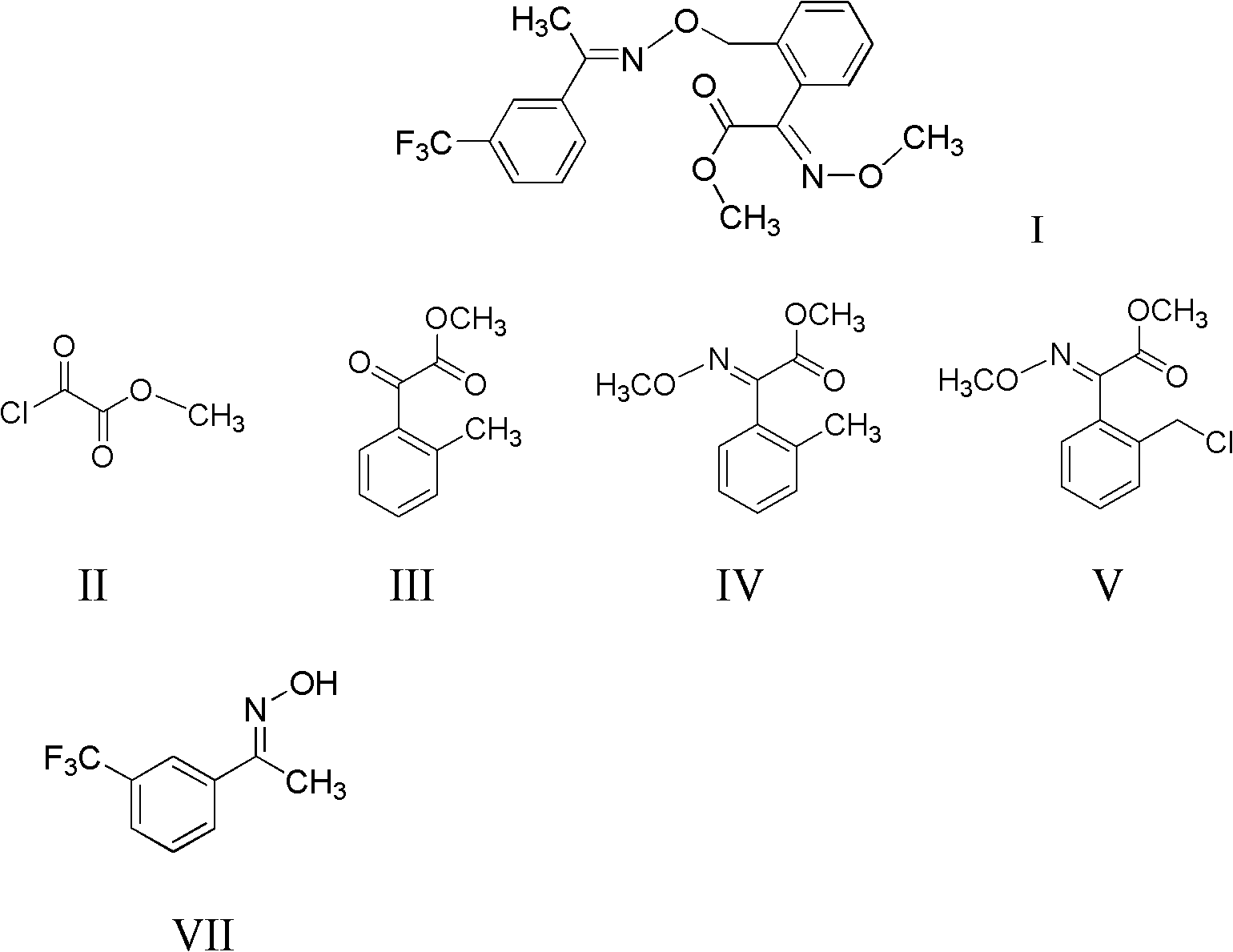

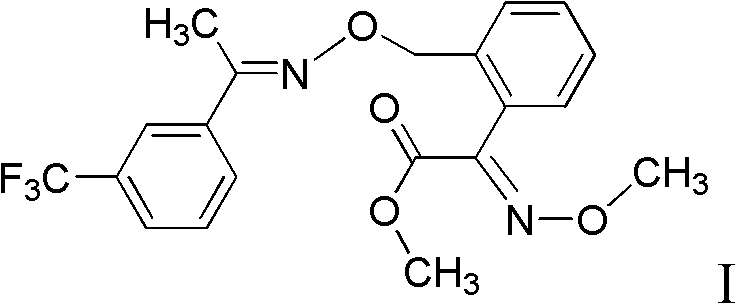

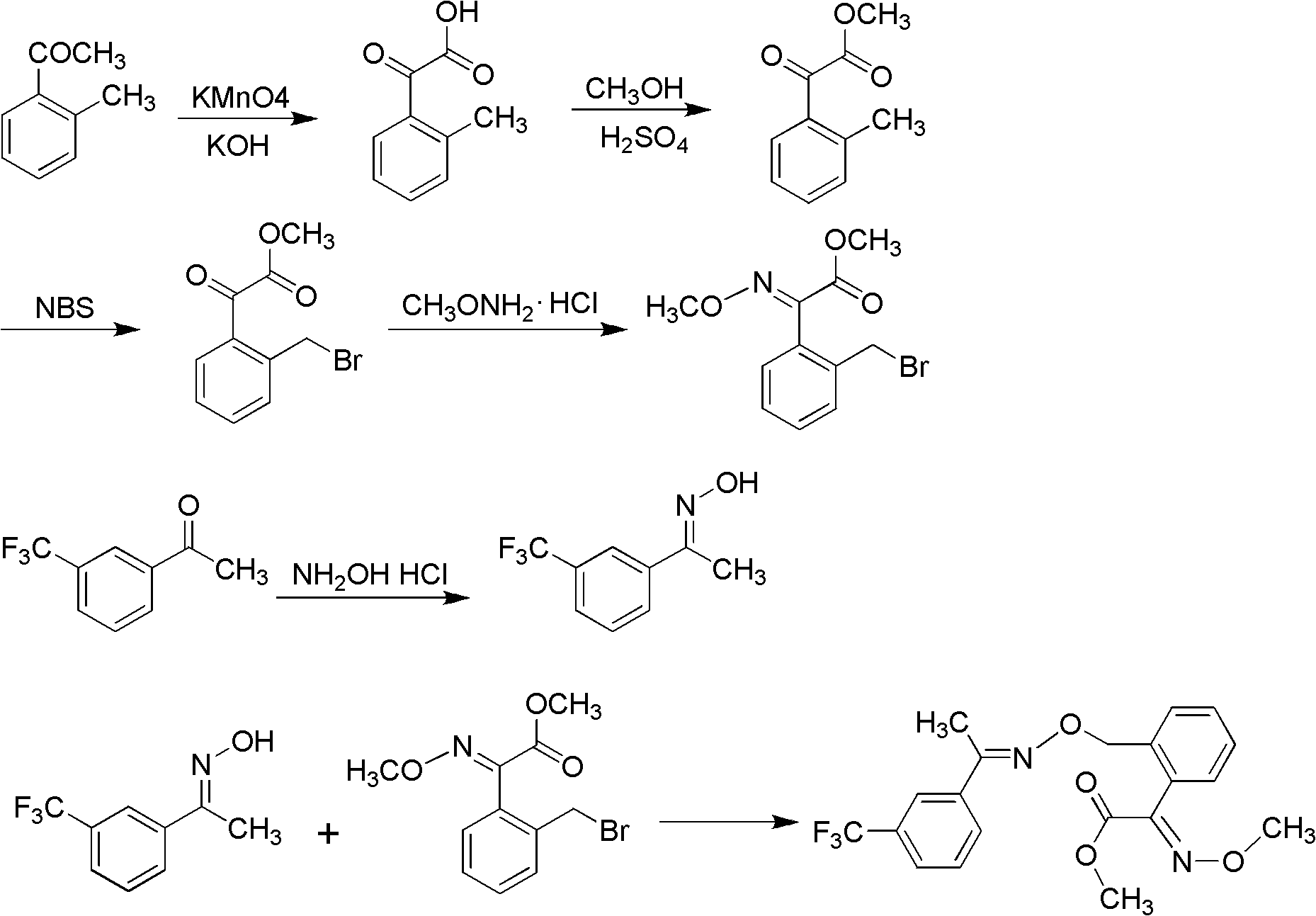

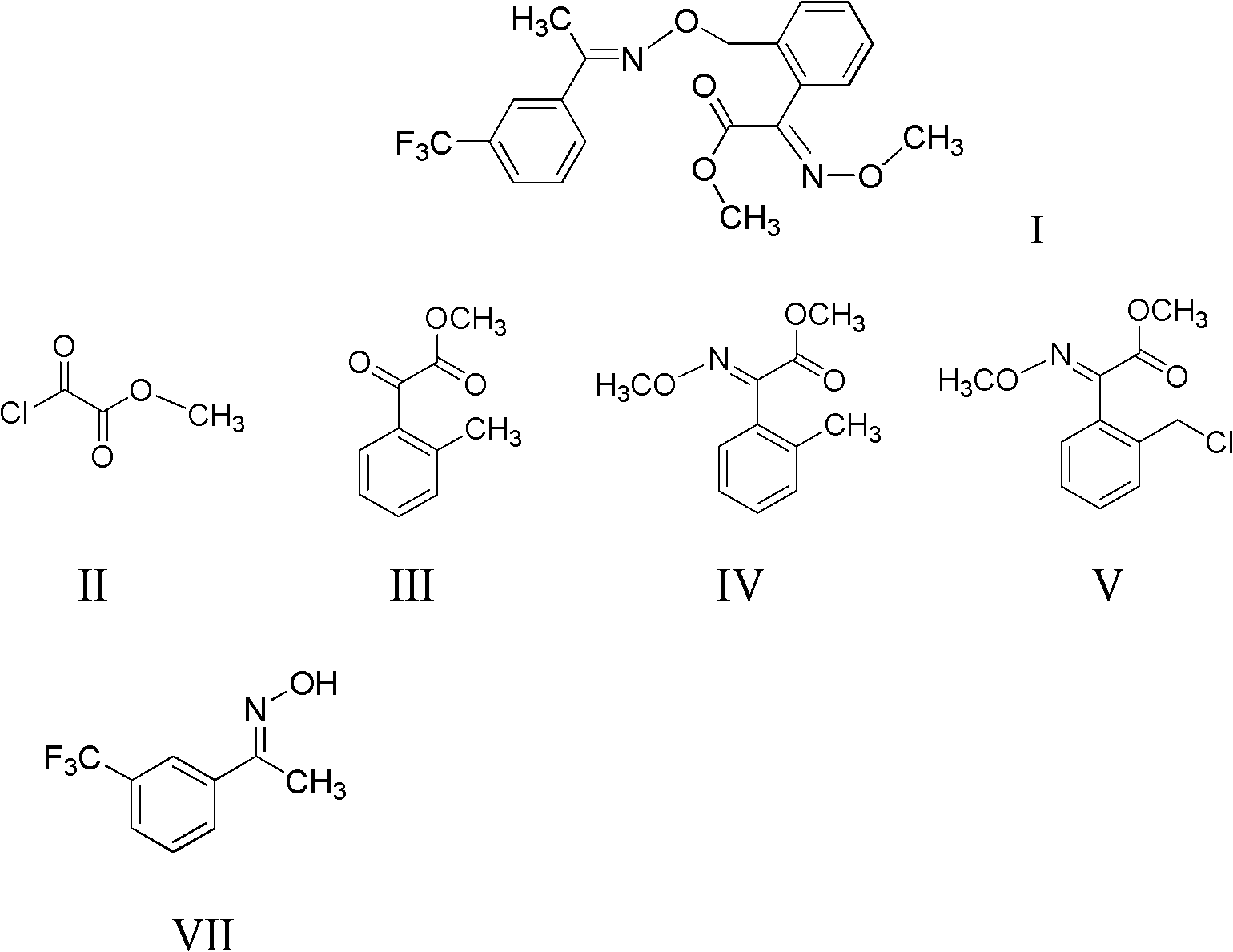

Method for preparing trifloxystrobin

InactiveCN101941921ARaw materials are cheap and easy to getHigh reaction yieldOximes preparationReaction stepOxalyl chloride

The invention discloses a method for preparing (E,E)-2-[1'-(3'-trifluoromethyl phenyl)-ethyl-imine-oxyl-tolyl]-2-carbonyl methyl acetate-O-ketoxime. The method comprises the following steps of: performing acylation reaction on toluene and methyl oxalyl chloride in the presence of anhydrous aluminum chloride to prepare 2-(2'-methyl phenyl)-2-carbonyl methyl acetate; reacting the 2-(2'-methyl phenyl)-2-carbonyl methyl acetate with methoxy amine hydrochloride to prepare (E)-2-(2'-methyl phenyl)-2-carbonyl methyl acetate-O-methyl ketoxime; and finally performing condensation reaction on the (E)-2-(2'-methyl phenyl)-2-carbonyl methyl acetate-O-methyl ketoxime and m-trifluoromethyl phenyl ethyl ketoxime under the action of alkaline substance to prepare the trifloxystrobin. The method has the advantages of a few reaction steps, simple synthesis process, readily available raw materials, mild reaction conditions, great industrial value and great social and economic benefit.

Owner:YUEYANG DIPU CHEM TECH

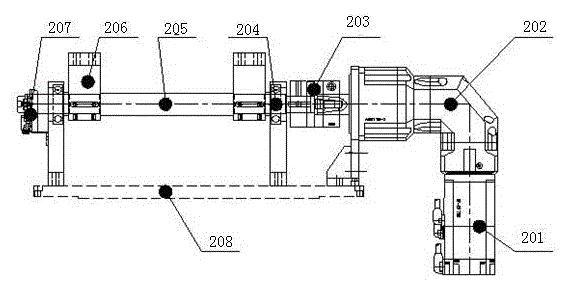

High-temperature soft-melted steel slag precise control high-efficiency cleaning crushing treatment device and method

PendingCN111826486ARealize precise operationImprove crushing and pulverization rateCombination devicesRecycling and recovery technologiesSlagFlue gas

The invention relates to a high-temperature soft-melted steel slag precise control high-efficiency cleaning crushing treatment device and method. The device comprises a movable tank type slag feeder (1), a bulk slag separation device (2), a bidirectional rotating high-temperature resistant crusher (3), a totally enclosed airtight cover (4), an automatic water pumping device (5), a high-temperatureresistant and wear-resistant hard crushing bed (7), a steel slag precision temperature measurement system, a smoke and dust cleaning treatment system and an intelligent monitoring operation system (17). Precise control, high-efficiency crushing and cleaning treatment of high-temperature soft-melted steel slag are achieved, after crushing, the particle size of over 90% of the steel slag is less than 300 mm, the dust concentration of outlet flue gas is 6-12 mg / Nm<3>, the device has the advantages of high steel slag powdering rate, high treatment efficiency, high degree of automation and high degree of cleanliness, the requirements of environmental protection policies are met, the economic benefits of steel slag treatment are greatly improved, and market prospects and technical advantages are good.

Owner:MCC ENERGY SAVING & ENVIRONMENTAL PROTECTION +1

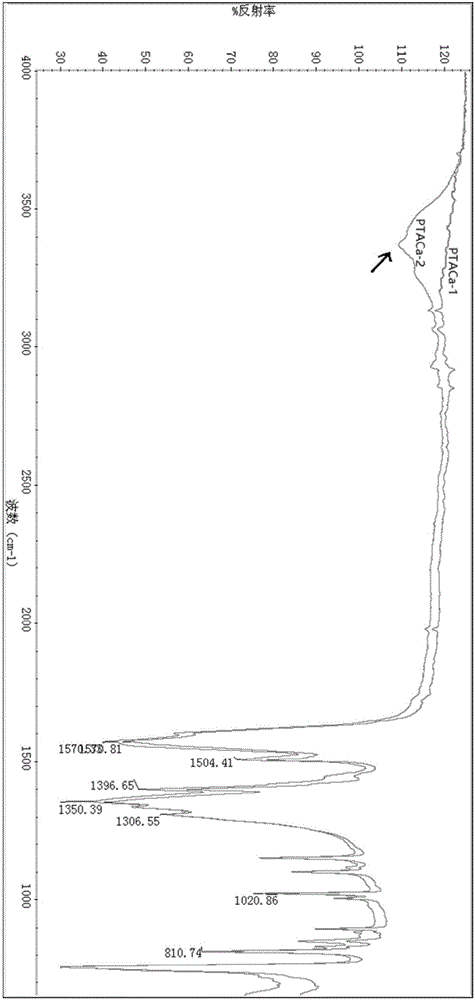

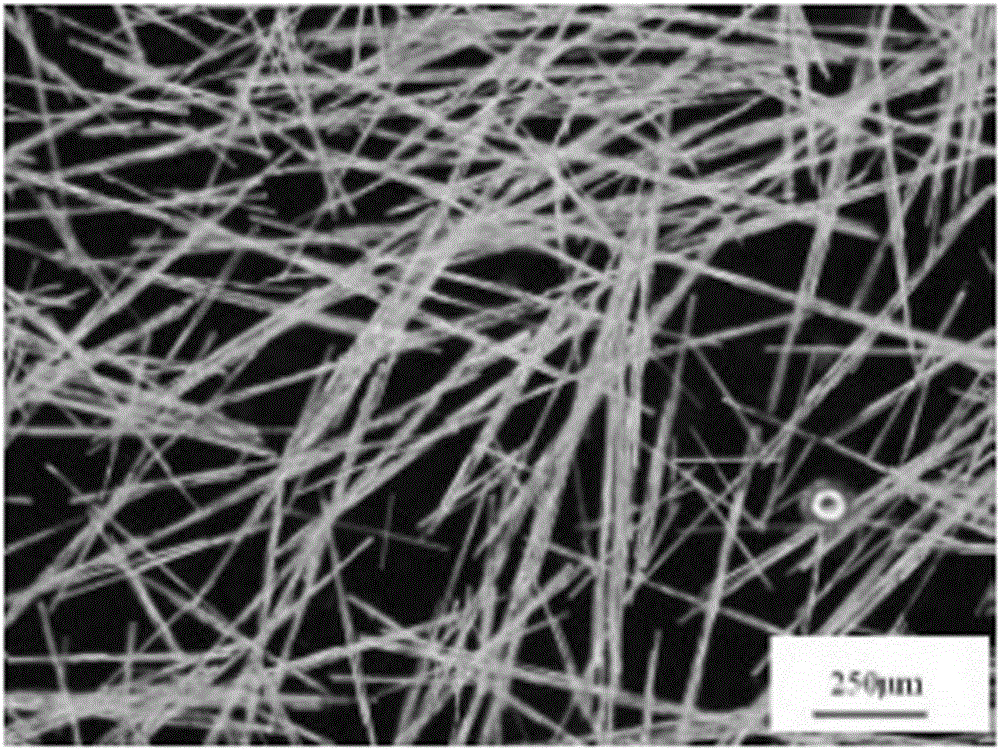

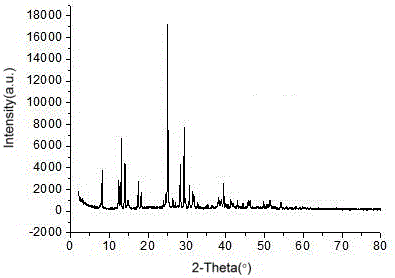

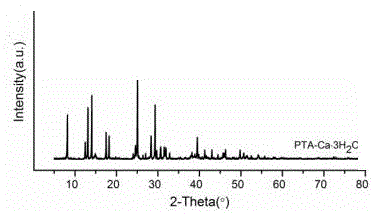

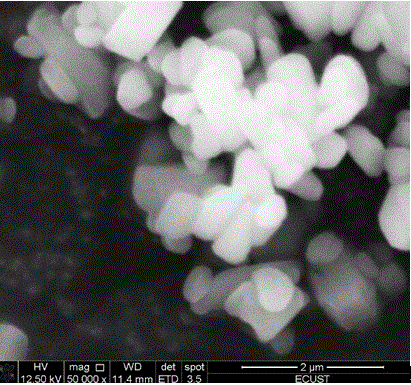

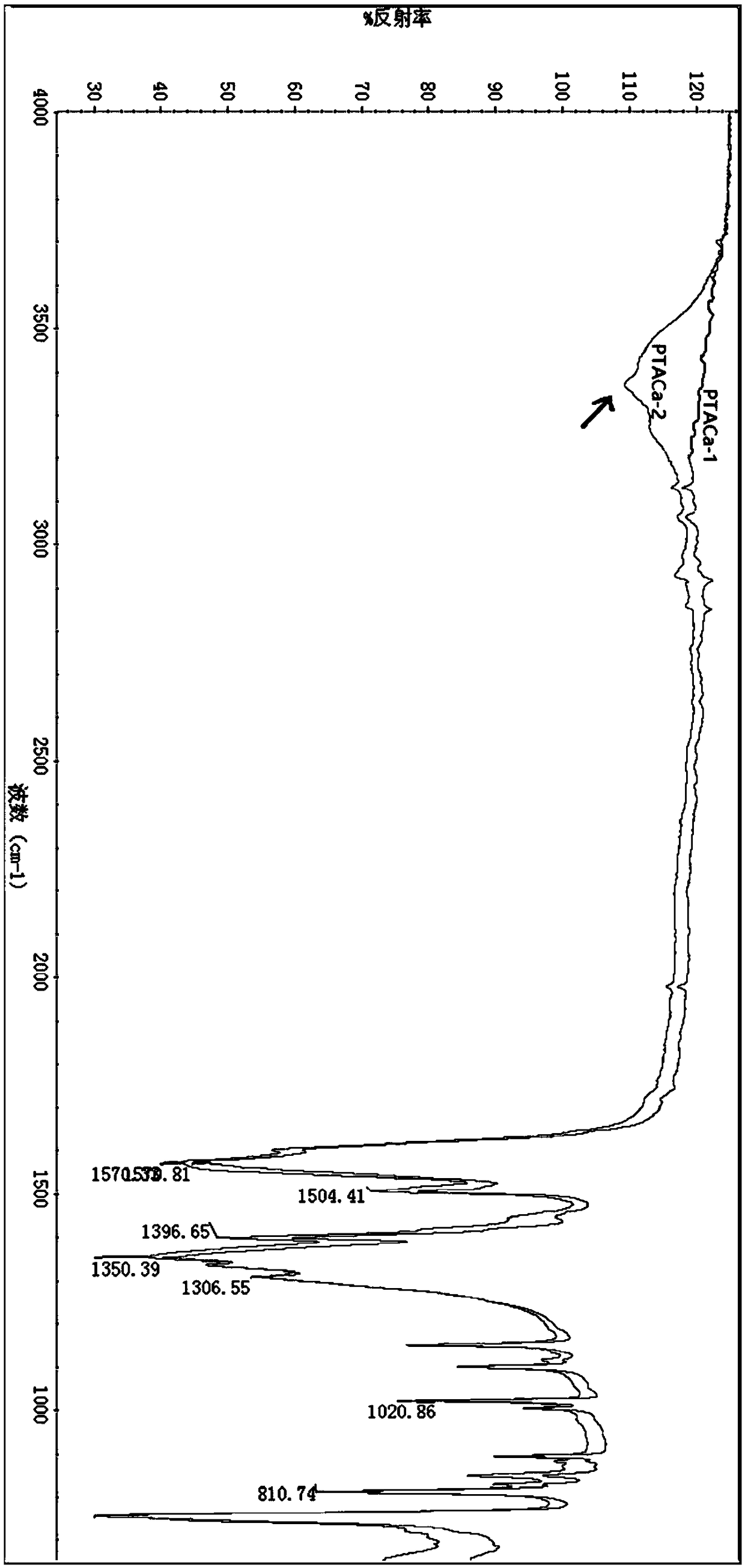

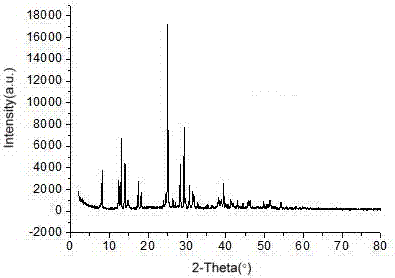

Preparation method and application of anhydrous calcium terephthalate whiskers

ActiveCN106119970AHigh crystal strengthLarge aspect ratioPolycrystalline material growthFrom normal temperature solutionsSlurryHigh pressure

The invention discloses a preparation method and application of anhydrous calcium terephthalate whiskers. The preparation method of anhydrous calcium terephthalate whiskers includes the steps of subjecting ammonium terephthalate solution and calcium hydroxide slurry to reaction to obtain a precursor, and continuing the reaction at 120-150 DEG C in a high-pressure kettle for 1-6 h to obtain the anhydrous calcium terephthalate whiskers. The preparation method is green, low in cost and high in cleanliness level. The production process is free of three wastes, and the obtained anhydrous calcium terephthalate whiskers have large length-diameter ratio, high crystal strength and significant reinforcement effect. During the preparation of the calcium terephthalate whiskers from ammonium terephthalate and calcium hydroxide, isolated ammonia water may continue to dissolve terephthalic acid for next cycle or remaining water is also suitable for reuse after ammonia gas is recycled by means of ammonia steaming, and the whole process is free of three wastes and belongs to clean production.

Owner:JIANGSU ATE DONGTAI NEW MATERIALS TECH

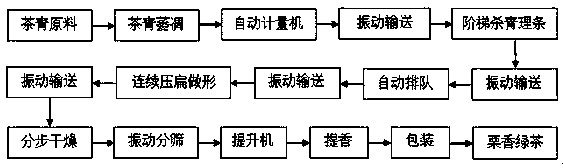

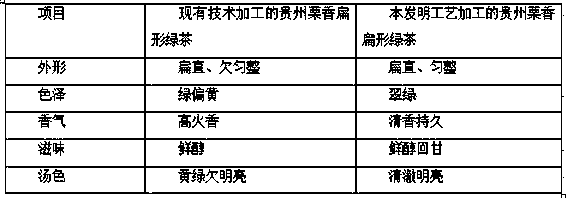

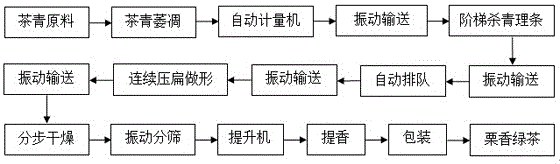

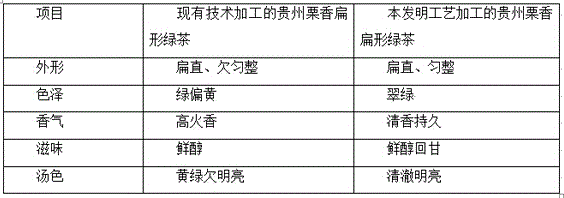

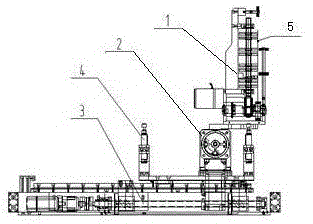

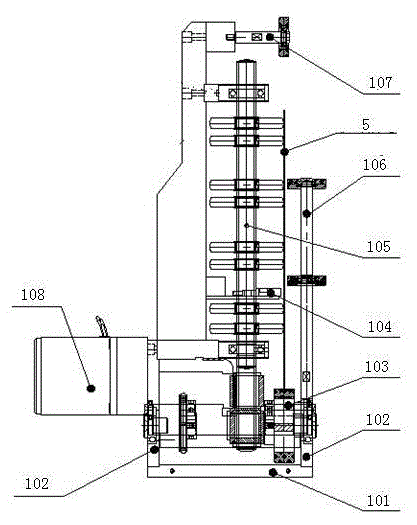

Method for processing Guizhou chestnut-fragrance flat green tea

ActiveCN104255966ARealize automatic continuous processing and productionHigh degree of cleanlinessPre-extraction tea treatmentEmeraldGreen tea

The invention relates to a method for processing green tea, in particular to a method for processing Guizhou chestnut-fragrance flat green tea. The method comprises the following steps: (1) withering tea green; (2) moving the water and settling the strips step by step; (3) automatically sequencing; (4) continuously flattening to shape; (5) drying step by step; (6) screening; (7) highlighting the fragrance. The Guizhou chestnut-fragrance flat green tea produced by using the method provided by the invention is flat, straight and uniform in appearance, emerald green in color, long-lasting in fragrance, fresh, mellow and sweet in taste. On-scale, automatic and continuous processing production of the Guizhou chestnut-fragrance flat green tea is achieved, the cleaning degree is high, the working intensity is greatly alleviated, the production efficiency is improved, the production cost is lowered, and the product quality is improved.

Owner:GUIZHOU TEA RES INST +1

A system and method for waste pyrolysis with adjustable oil, gas and charcoal

ActiveCN104087340BSave the hassle of frequent replacementLightweightSolid waste disposalSludge treatment by pyrolysisFlue gasWorking temperature

The invention relates to a waste pyrolysis system with adjustable oil, gas and carbon and a method. The system comprises a pre-reaction section, a main reactor, a conditioner and a particle separator. The front of the pre-reaction section is connected to a feeder and the tail of the pre-reaction section is connected to the main reactor. The conditioner is connected after the main reactor. The particle separator is connected after the conditioner. In specific, waste having a water content not more than 60% is fed into the pre-reaction section through the feeder, reacted waste is fed to the main reactor, residue coke generated after the reaction is finished is fed into the conditioner and a generated volatile material is discharged in a forced manner into the conditioner to be contacted, reacted and conditioned with the residue coke at the same time. The conditioner achieves conditioning of the residue coke and the volatile material at the same time. The volatile material after being conditioned is fed into the particle separator to output a clean volatile material. The residue coke after conditioning has a calorific value of 3.37-6.74 MJ / kg, and can be used as building raw materials or is conveyed to a sanitary landfill. The working temperature of the pre-reaction section is 105-298 DEG C and an inert gas or flue gas is fed into the pre-reaction section. The working temperature of the main reactor is 450-650 DEG C. The working temperature of the conditioner is 700-900 DEG C. The system and the method can obtain oil with better quality and more combustible gases and are adapt to changes of the water content of the waste.

Owner:上海济德能源环保技术有限公司

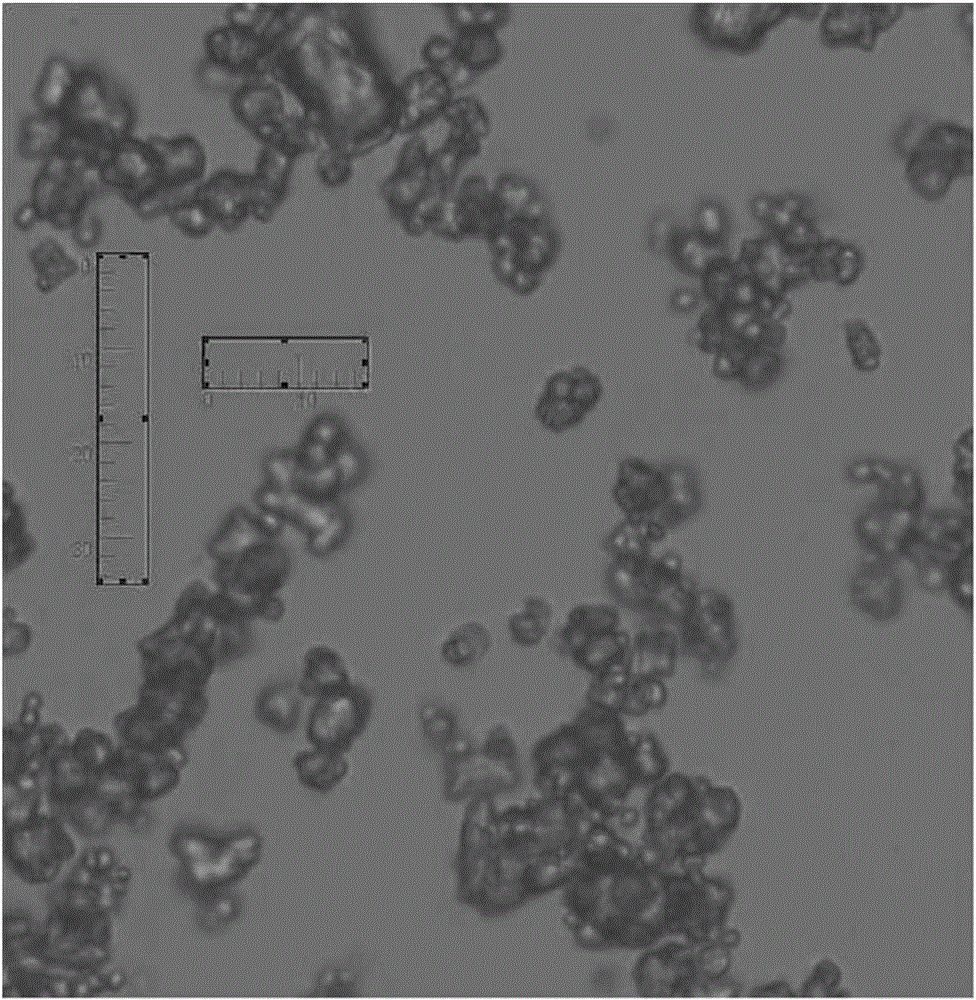

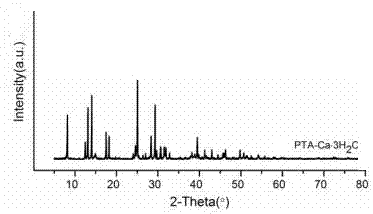

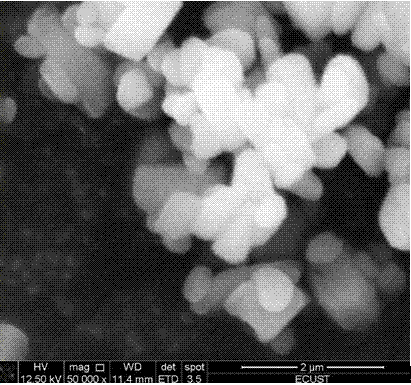

Clean preparation method of submicron calcium terephthalate

ActiveCN105967999AHigh degree of cleanlinessReduce environmental costsOrganic compound preparationCarboxylic acid salt preparationCalcium hydroxideEvaporation

The invention discloses a clean preparation method of submicron calcium terephthalate. The preparation method comprises the following steps: a calcium hydroxide slurry with a multihole nozzle is introduced from the upper end, and an ammonium terephthalate solution with a dispersion modifier is introduced through the side surface of a high-speed centrifugal atomizer; the calcium hydroxide slurry and ammonium terephthalate solution are sufficiently mixed in a mixing chamber of a jet reactor, and enter a closed tank reactor via a diffuser chamber; and the materials are heated to the specified temperature while stirring to continue react for some time, thereby obtaining the calcium terephthalate. The method is green and environment-friendly, has high clean degree, and does not generate three wastes in the preparation process; and the obtained product is submicron particles. In the submicron calcium terephthalate preparation process, the separated ammonia water can continue dissolving terephthalic acid to enter the next circulation, or after ammonia gas is recovered by an ammonia evaporation technique, the residual water can be recycled, so the whole process does not generate three wastes and belongs to clean production.

Owner:JIANGSU ATE DONGTAI NEW MATERIALS TECH

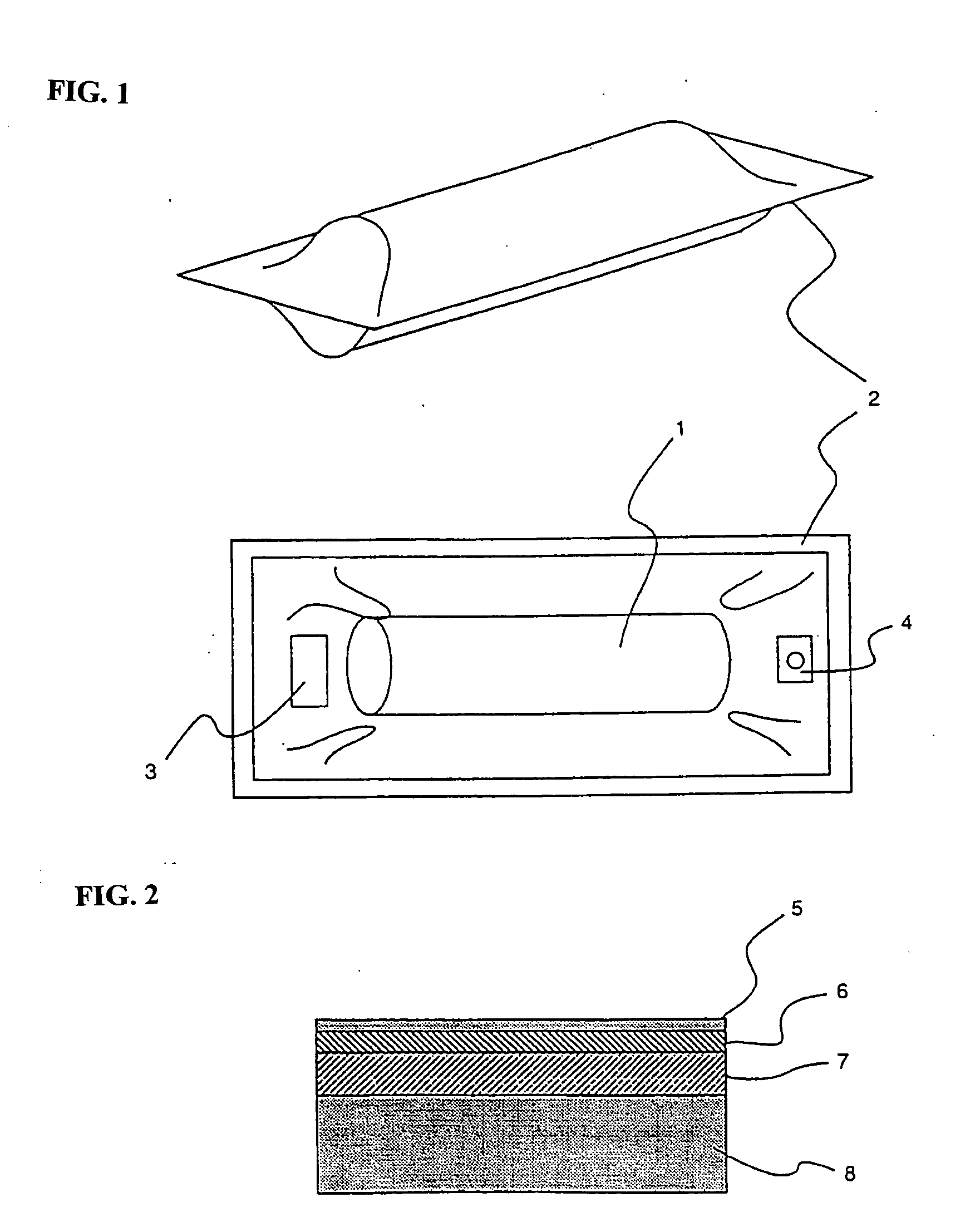

Porous poly(vinyl acetal) resin body having a high degree of cleanliness, a process of preparing the same, and a method of storing the same

InactiveUS20060000191A1High degree of cleanlinessImprove cleanlinessCapsCap application using vaccuumComposite materialContamination

A process of preparing and a method of storing porous poly (vinyl acetal) resin body. A method of storing the porous body involves keeping the porous body wet and free of contamination with organic substances, dissolved ions, and other fine particles. The storing method also involves keeping the body free of mold and avoiding pre-cleaning after a prolonged period of storage.

Owner:AION

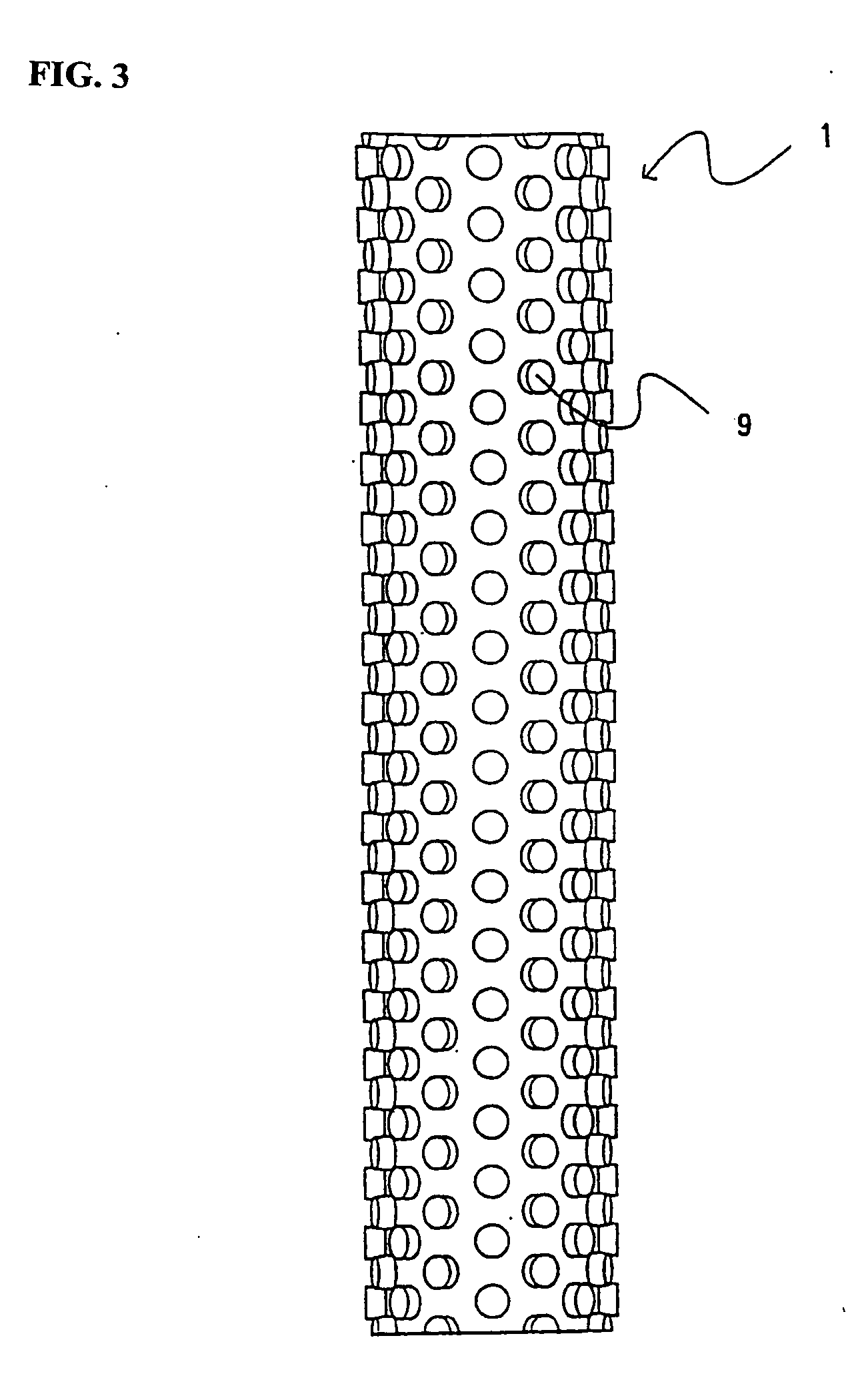

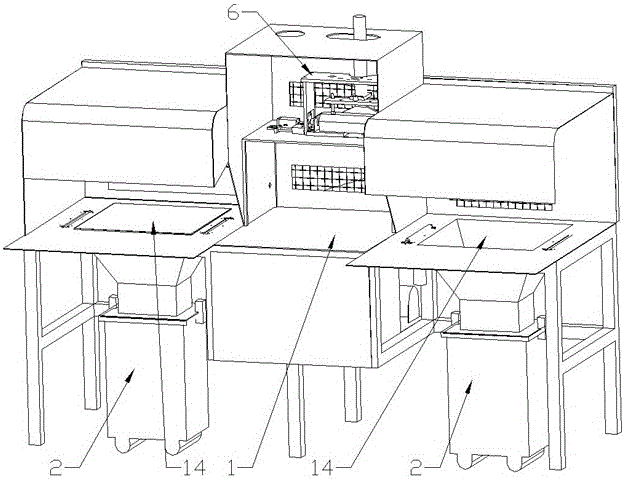

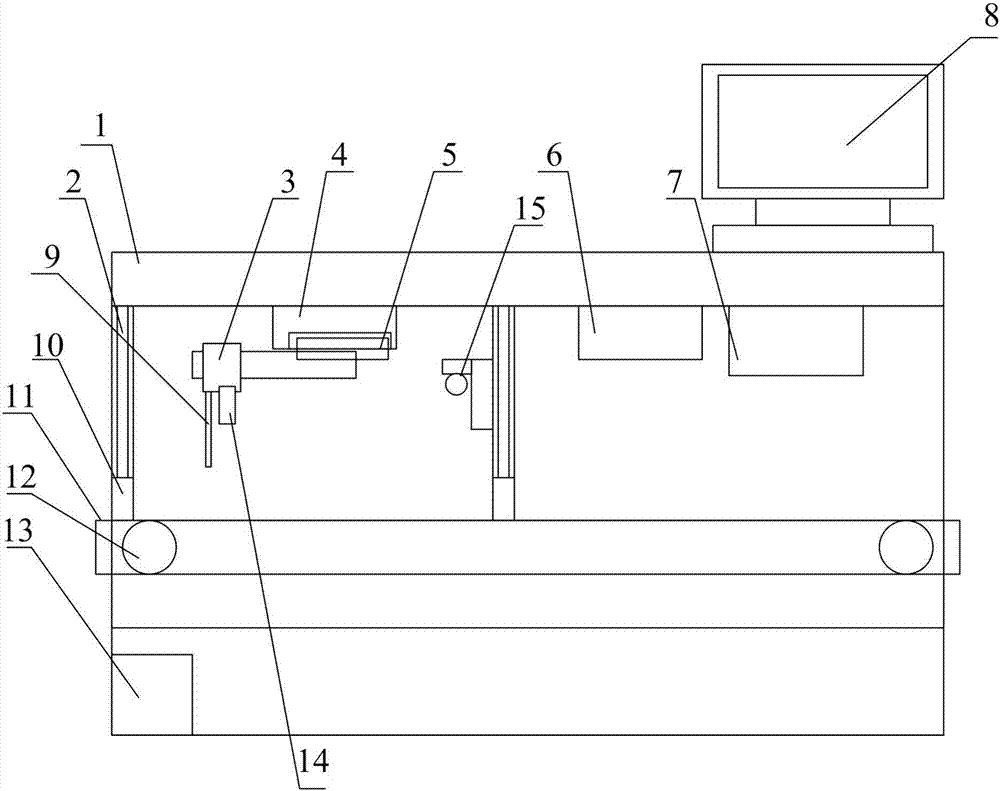

Brand new recycled part production line

InactiveCN105710116AHigh degree of cleanlinessLow costSolid waste disposalProduction lineEngineering

The invention aims at providing a brand new recycled part production line which is simple in structure, safe, reliable, high in utilization rate and good in assembling quality. The brand new recycled part production line comprises a disassembly workstation and an installation line. The workstation is arranged on one side of the installation line. The disassembly workstation comprises a machine table. A waste powder removing device and waste powder collecting barrels are arranged on the machine table. The waste powder removing device is connected with a peripheral suction machine. The installation line comprises a conveying belt, a feeding frame and a discharging frame, wherein the feeding frame and the discharging frame are arranged at the two ends of the conveying belt. A tray back-conveying belt is further arranged below the conveying belt. The two ends of the tray back-conveying belt are connected to the parts inside the feeding frame and the discharging frame. The feeding frame and the discharging frame are each provided with a lifting device. The conveying belt, the lifting device on the discharging frame, the tray back-conveying belt and the lifting device on the feeding frame are sequentially connected end to end to form a circulating conveying belt. The brand new recycling part production line can be applied to the field of printing supplies.

Owner:KOLION TECH

Environment-friendly type crust leather production method

ActiveCN103060488BEmission reductionCreate pollutionTanning treatmentPre-tanning chemical treatmentWastewaterChromium

The invention discloses an environment-friendly type crust leather production method, and aims at solving the problems that in a crust leather production method using conventional chrome tanning as basis, plenty of chromium ions are contained in waste water and cannot be effectively processed, plenty of leather wastes with chrome are also generated, and the environment is seriously polluted. The production method comprises the following steps of non-pickling tanning, retanning filling, dyeing fat liquoring and chrome retanning. The method adopts non-pickling non-chrome tanning technology, so solid wastes with the chrome cannot be generated. At the same time, through mutual matching with other procedures, finished leather shrinkage temperature and performance can be effectively improved so as to meet demands of leather production. At the last, the chrome retanning is adopted, only a path of waste water with the chrome is generated, waste water quantity is small, and the waste water is easy to recover and process. Therefore, compared with an existing crust leather production method using a chrome tanning method as basis, cleaning degree is high, the waste water quantity with the chrome can be effectively reduced, and the waste water is convenient to recover and process. At the same time, the leather wastes with the chrome cannot be produced, and the method is environment-friendly.

Owner:四川亭江新材料股份有限公司 +1

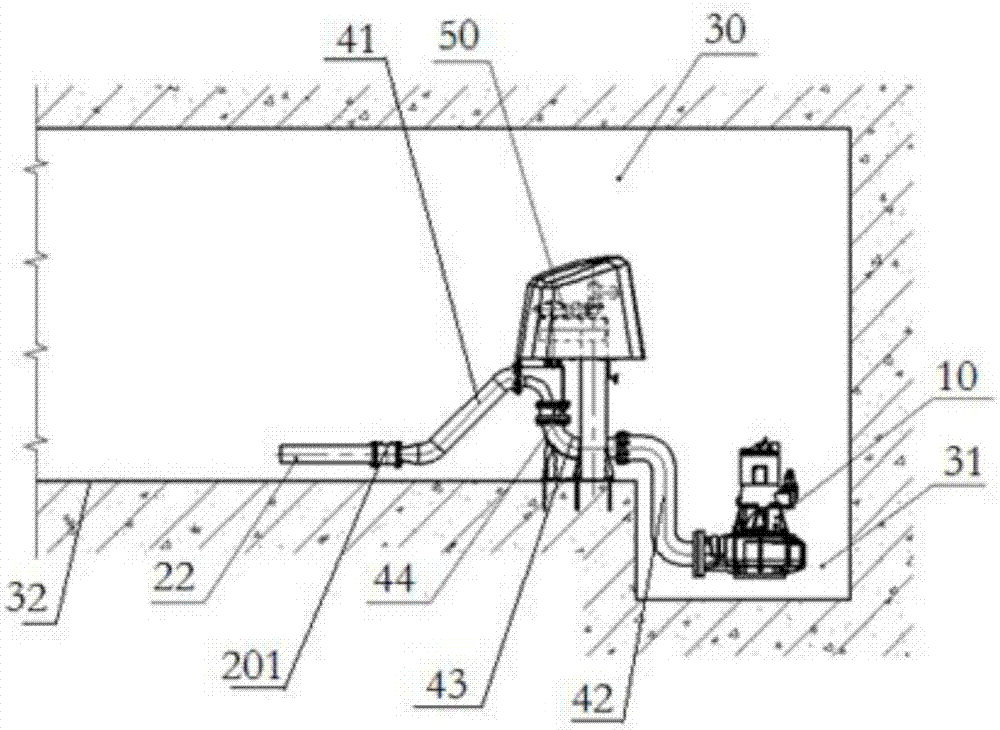

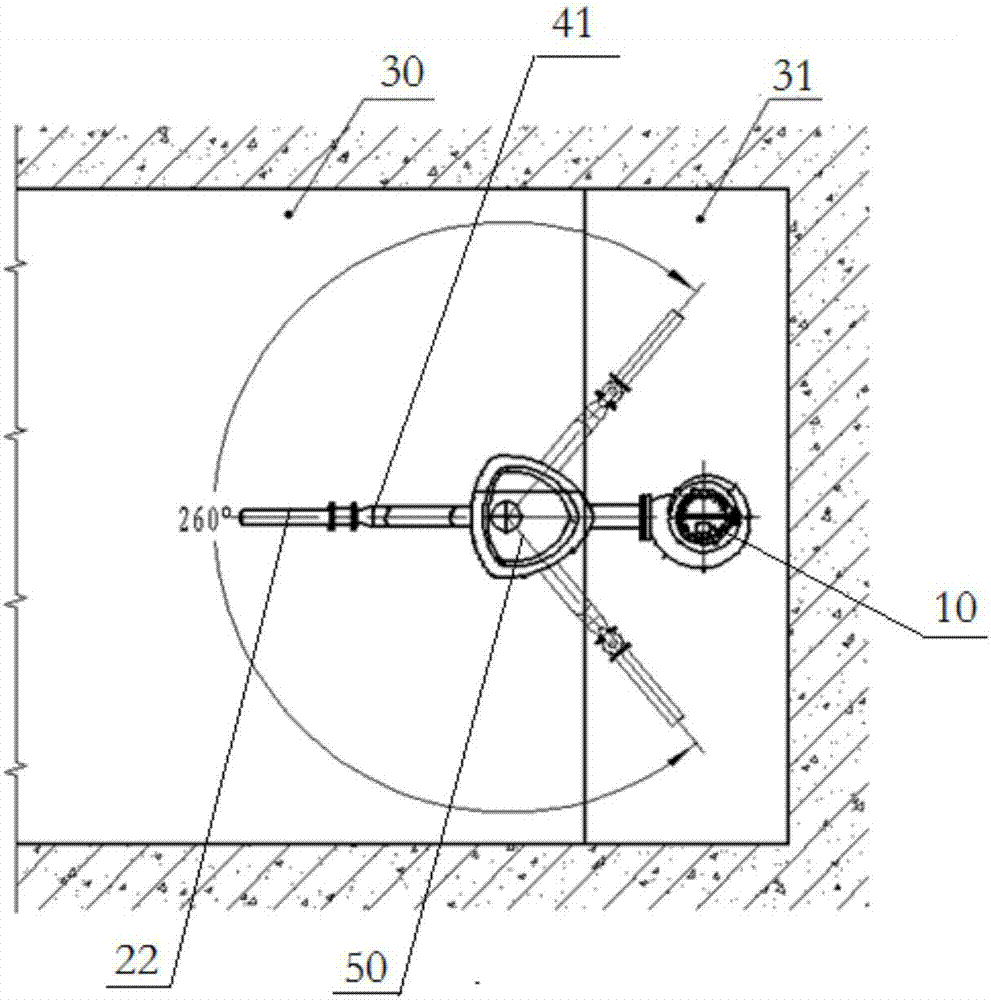

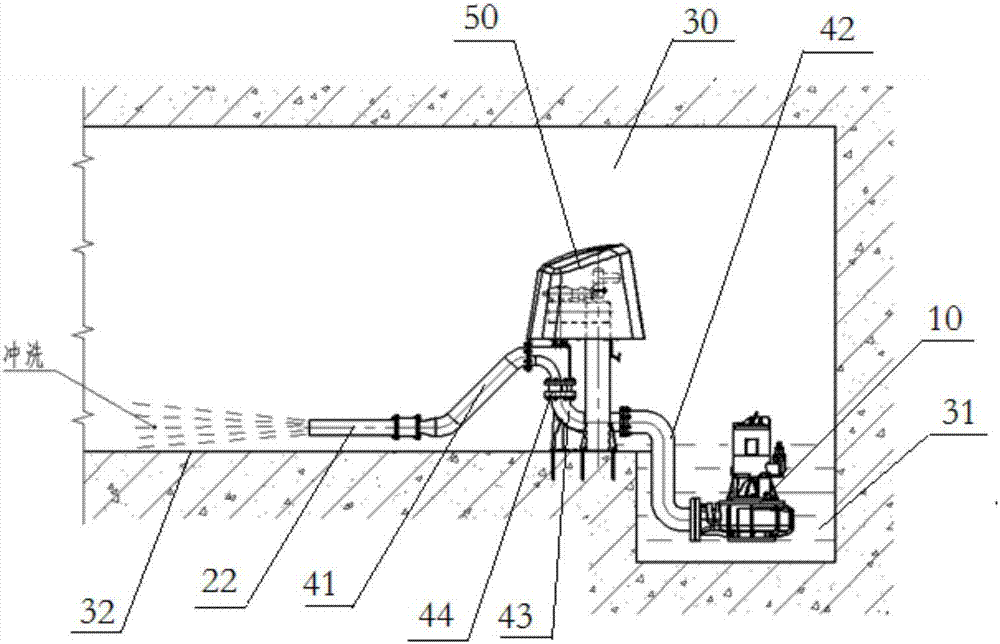

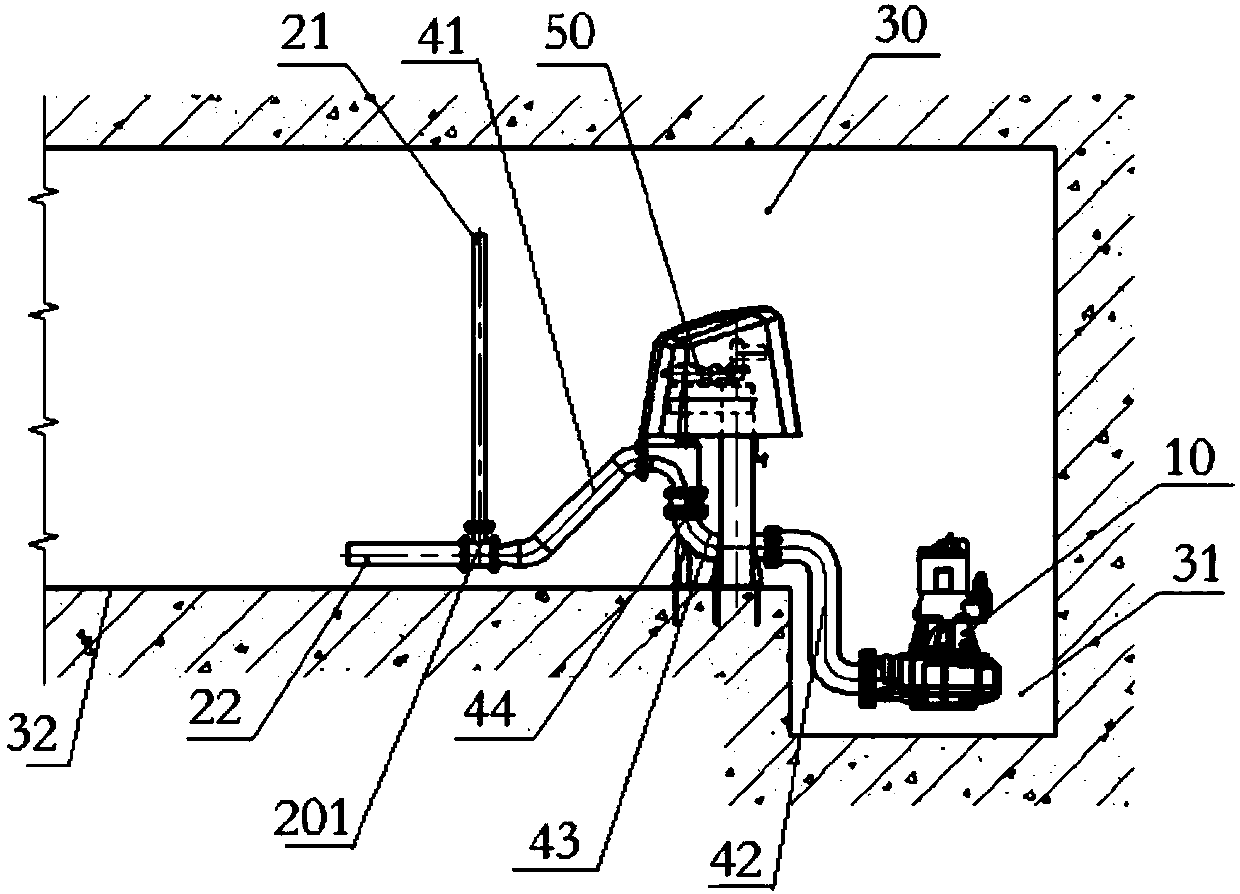

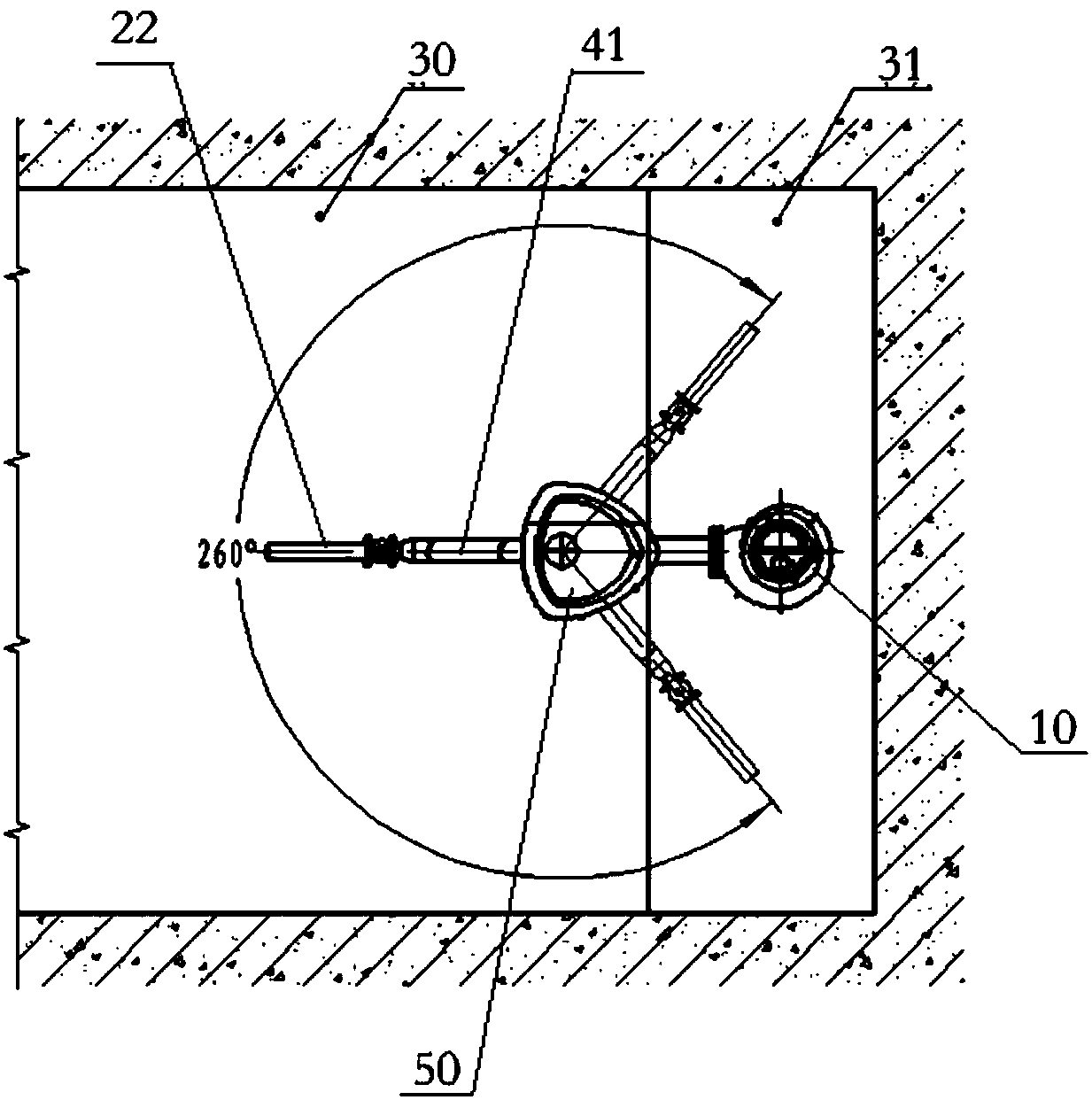

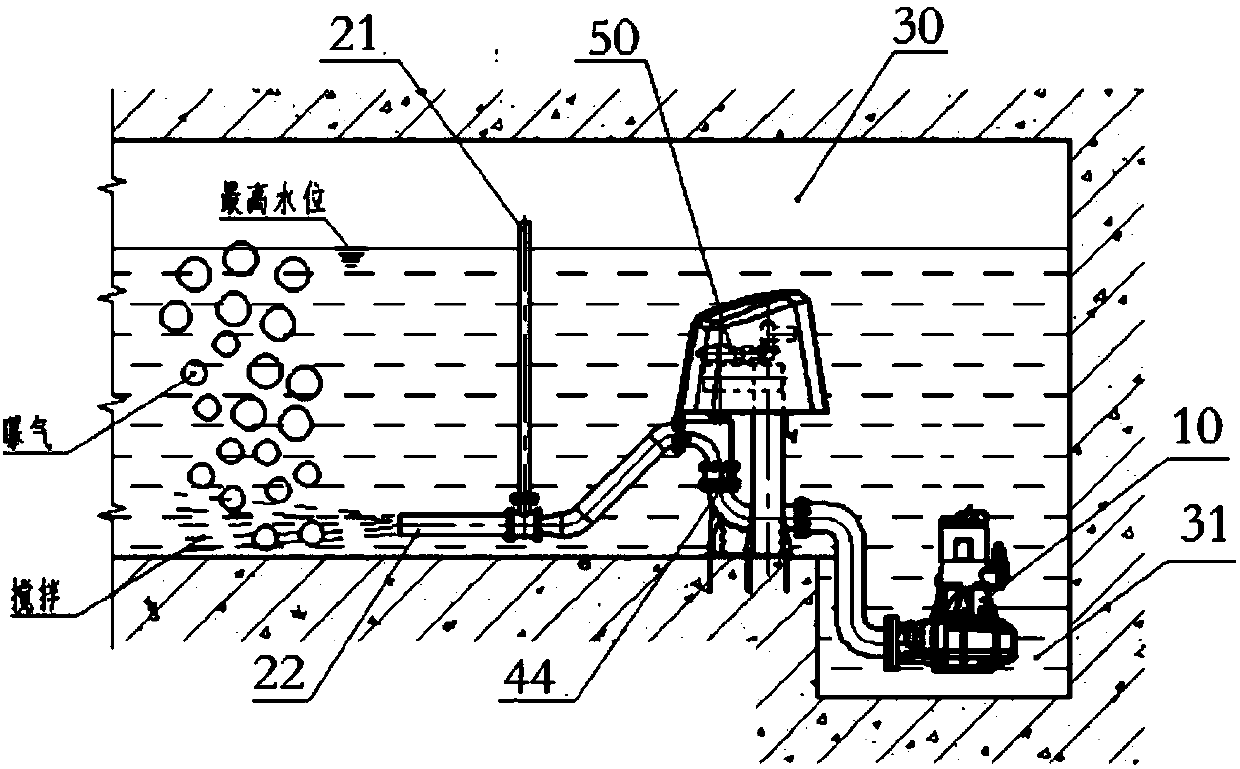

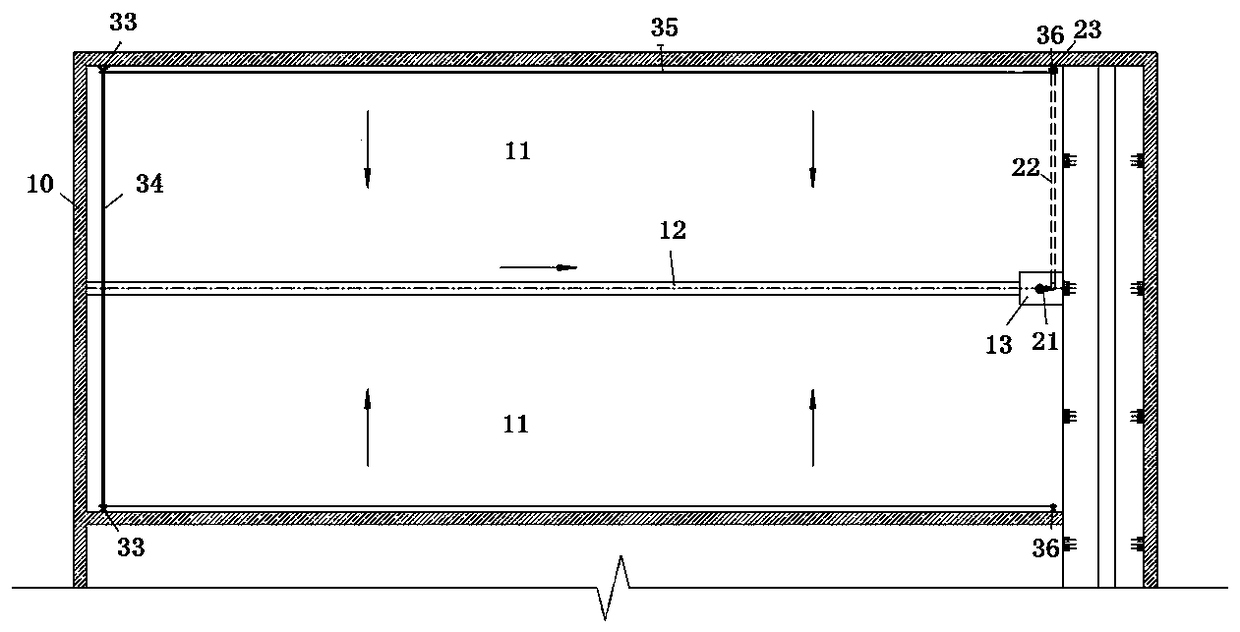

Rainwater storage tank ejection-type flushing device, control method and rainwater storage tank

The invention discloses a rainwater storage tank ejection-type flushing device, a control method and a rainwater storage tank. The rainwater storage tank ejection-type flushing device comprises a power pump and a rotating driver, the power pump is arranged in a water collection pit and used for delivering rainwater in the water collection pit into an ejection pipe to be ejected onto the second surface of the rainwater storage tank to flush the same, and the rotating driver is used for driving the ejection pipe to rotate in the rainwater storage tank. The flushing device can utilize the power pump to extract water in the water collection pit to vigorously flush the bottom in the rainwater storage tank when sewage in the rainwater storage tank is about to be drained. In the process of ejection-type flushing, the ejection pipe can rotate within a range of 0-260 degrees (namely being adjustable), in other words, the ejection pipe can rotate underwater to eject water flow, so that the flushing device is wide in flushing range, and the bottom of the rainwater storage tank can be cleaned in an omnibearing manner and can be flushed more cleanly.

Owner:WUHAN SHENGYU DRAINING SYST

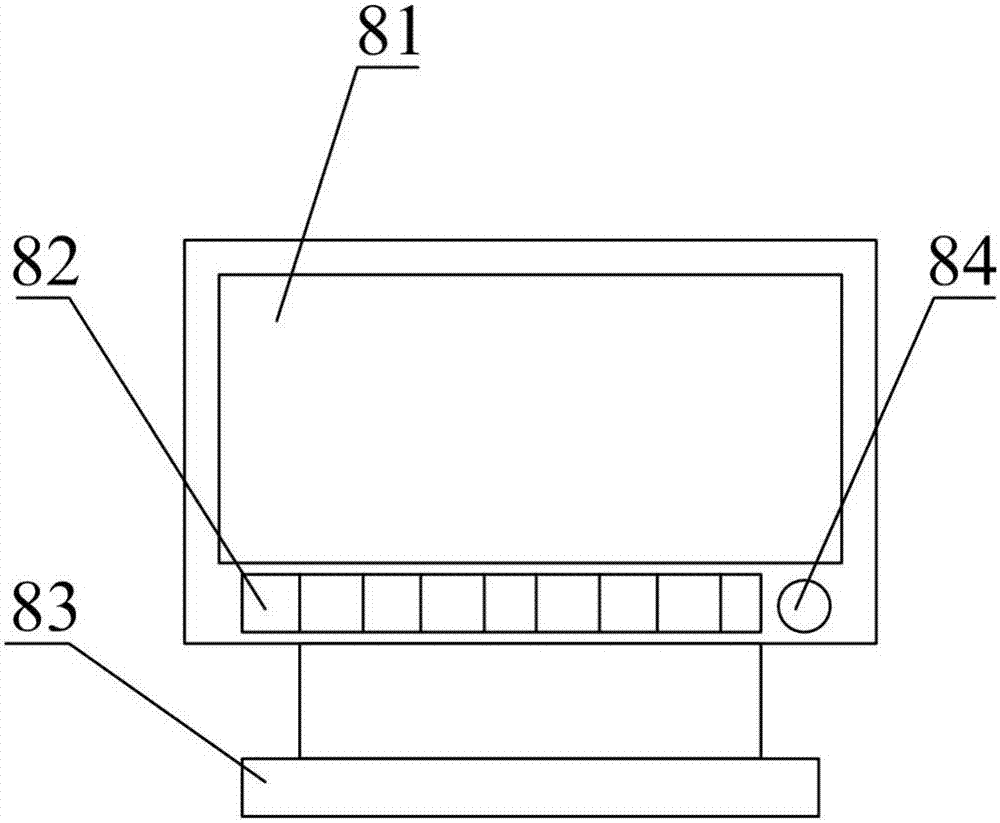

Energy-saving ink-jet device

InactiveCN107571635AImprove securityHigh degree of cleanlinessOther printing apparatusRemote controlAcousto-optics

The invention provides an energy-saving ink-jet device which comprises a workbench, a lifting rod, a slider, a connecting column, a sliding shaft, a drying device, a cooling device, a remote control structure, an ink-jet device, isolation doors, a conveying belt, a conveying shaft, a motor, a printing device and a sterilization device, wherein the lifting rod is arranged at the upper part of the isolation door, the sliding device is arranged on the upper portion of the ink-jet device, the remote control structure comprises a display screen, a button control bench, a base and an alarm lamp, thedisplay screen is arranged on the upper portion of the button control bench, and the alarm lamp is arranged on the right side of the button control table. According to the invention, the remote control structure and the isolation doors are arranged, and the alarm lamp specifically adopts an acousto-optic alarm lamp, so that a user is reminded of the current working state and an alarm can be givenout in time when accidents happen. The safety is improved, and the two isolation doors are arranged, so that the cleanness degree can be improved, the safety degree can be improved, and the usage canbe guaranteed.

Owner:天津圣文纸制品股份有限公司

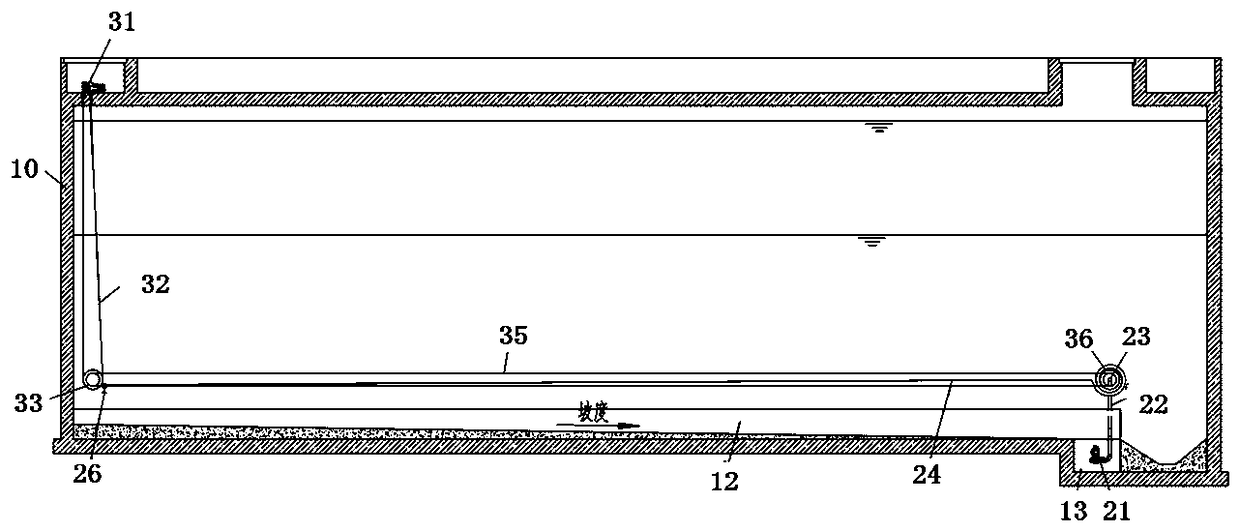

Aeration integration device, control method and rainwater rainwater storage tank

InactiveCN107620371AIncrease dissolved oxygen contentAvoid blackeningTreatment using aerobic processesSewerage structuresEmulsionSewage

The invention discloses an aeration integration device, a control method and a rainwater storage tank. The aeration integration device comprises a power pump and a rotating driver; the power pump is connected with an injection device through a pipeline; the rotating driver is used for driving the injection device to rotate in the rainwater storage tank; the injection device comprises an air inletpipe and an injection pipe, wherein the air inlet is connected with the atmosphere, and the injection pipe is arranged in the rainwater storage tank and connected with the air inlet pipe and the pipeline. According to the integration device, the dissolved oxygen content in sewage can be increased by injecting air-water emulsion, omnidirectional mixing can be conducted on the sewage in the rainwater storage tank, and the storage tank bottom with a large amount of sediment deposition is sprayed.

Owner:WUHAN SHENGYU DRAINING SYST

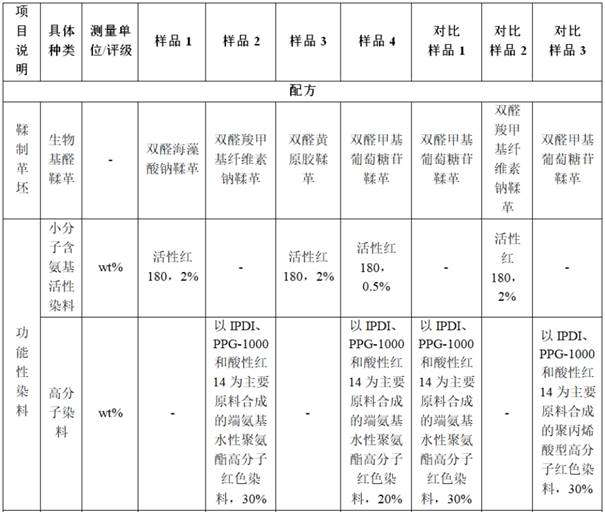

Method for producing low-odor clean vehicle interior decoration leather by using biological enzyme technology

ActiveCN109554510AFatliquor absorbs evenlyImprove smellPre-tanning chemical treatmentBiotechnologyFiber

The invention relates to a method for producing low-odor clean vehicle interior decoration leather by using a biological enzyme technology, wherein the method comprises: meat removal, liming, deliming, softening degreasing, pickling, tanning, re-tanning, dyeing, fatliquoring, drying, milling, base coating, middle coating, embossing, top coating and other steps. According to the present invention,the biological enzyme is introduced and is used before pretreatment, tanning and retanning of the raw skin, such that the efficiency of liming hair removal, degreasing, deodorization and other processes is improved, the use of strong acid, strong alkali and a large amount of surfactants is reduced, and the generation of pollutants is reduced; due to the strengthened degreasing treatment effect, the protection effect on the leather fiber is significant, and the problems of loose grain and the like of the product are improved; and the leather made of the new material through the new process hasexcellent interfibrilliary substance removing effect, low odor, low atomization and other low emission characteristics due to the complete degreasing.

Owner:HAINING SENDE LEATHER +1

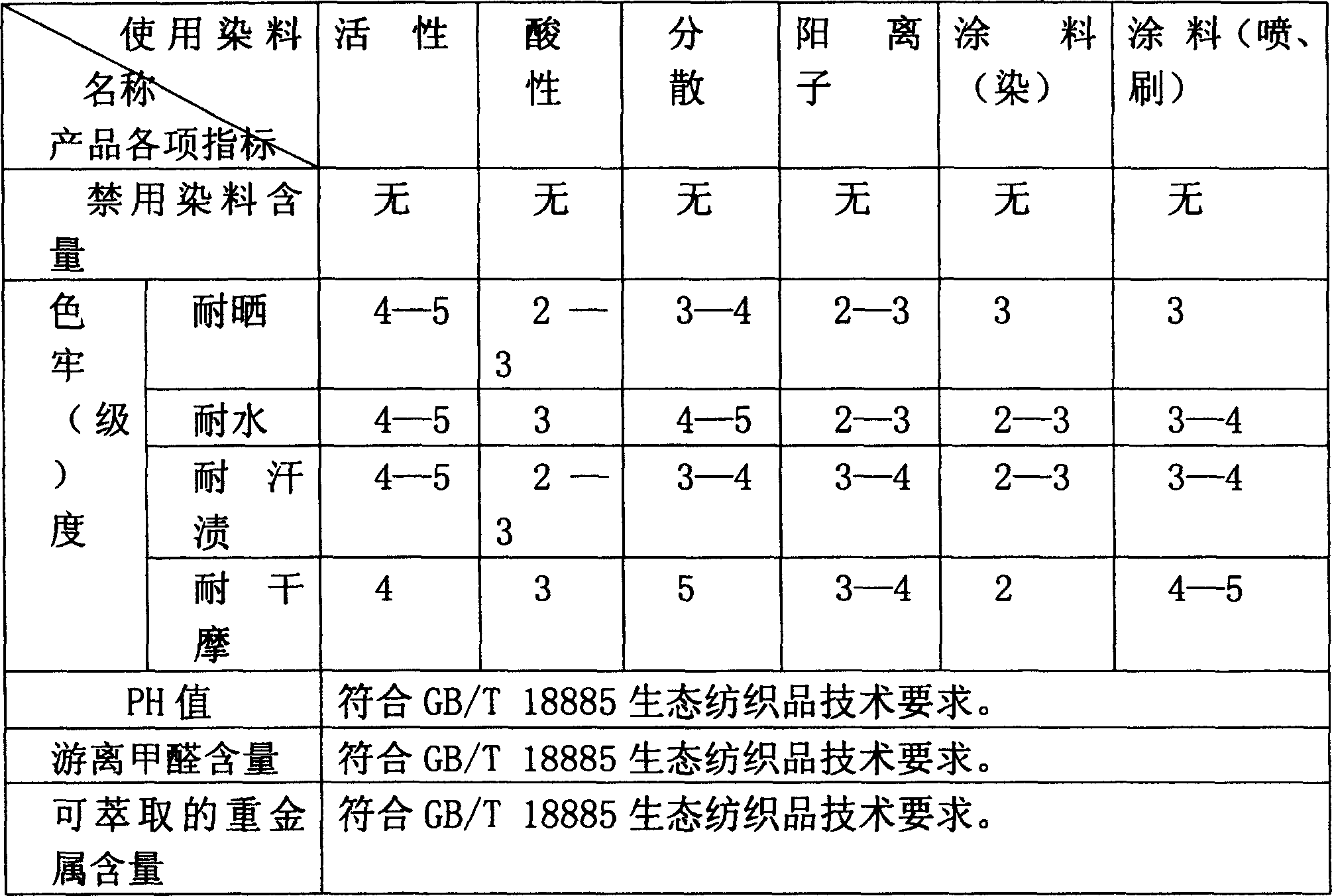

Assembled integrated process of 3D memory and spray painting and lithograph

ActiveCN1268805CShort processTo meet the objective requirements of the ever-changing fashionHeating/cooling textile fabricsDyeing processSlurryEngineering

This is a complex arrangement technology of three dimensions recall and inject drawing and printing for ready-to-wear clothes. It contains following steps: To do the arrangement for the ready-to-wear clothes: To arrange of polymerization and skein for them. Be arranged them in three dimensions in finished form by thermo-compression or to spur paint paste on their surface. To cure them on fire to fix colors, then to arrange them in their dimensions and pack them.

Owner:JIANGSU HUAYI GARMENT CO LTD

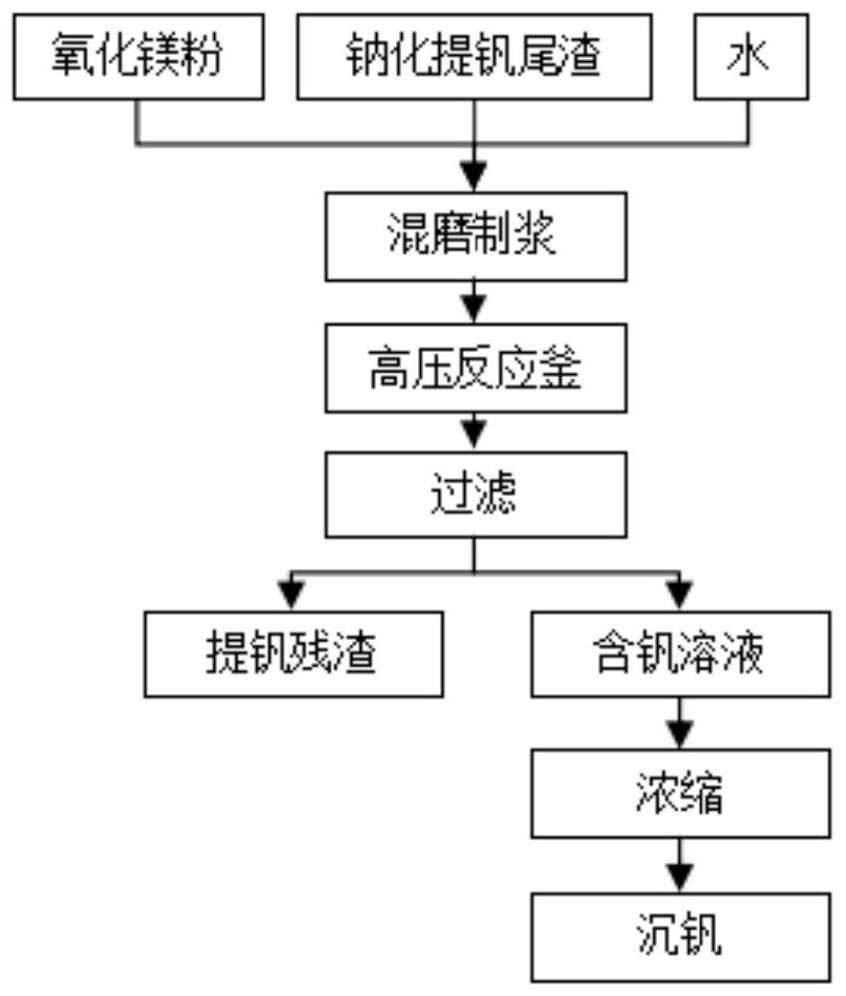

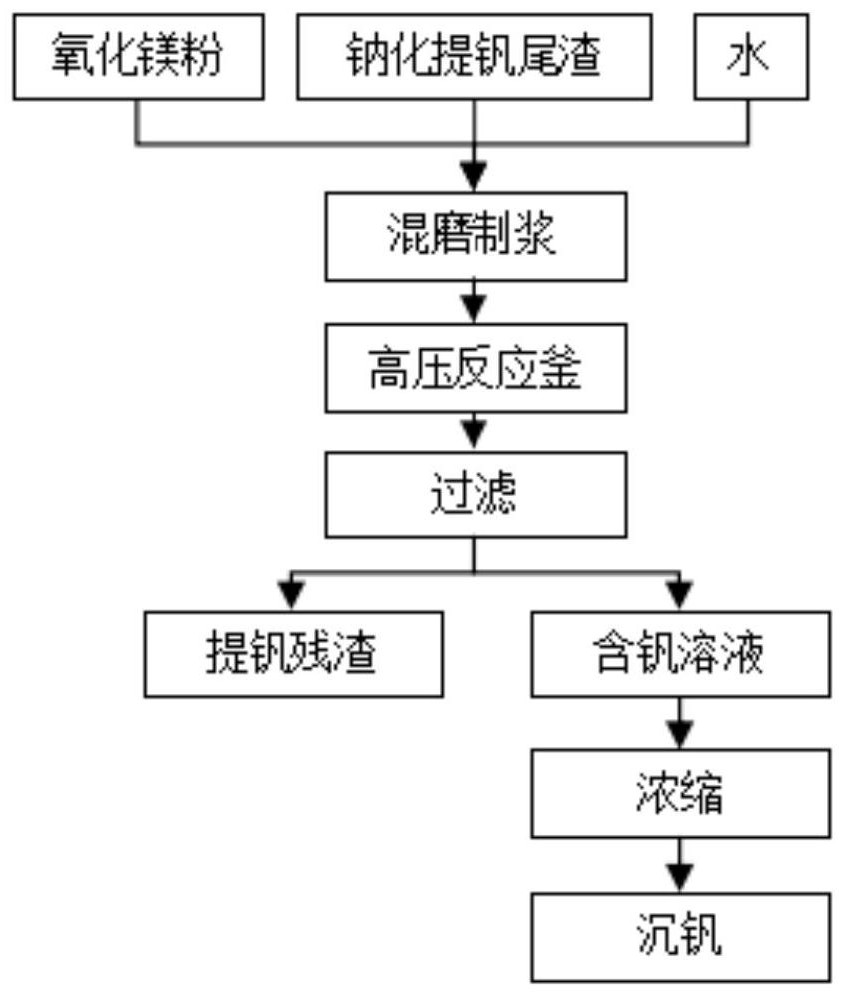

A kind of vanadium extraction method of sodium vanadium extraction tailings

ActiveCN112095024BHigh degree of cleanlinessImprove leaching rateProcess efficiency improvementChemical industrySlurry

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

A kind of preparation method and application of anhydrous calcium terephthalate whisker

ActiveCN106119970BHigh crystal strengthLarge aspect ratioPolycrystalline material growthFrom normal temperature solutionsCalcium hydroxideAmmonia gas

The invention discloses a preparation method and application of anhydrous calcium terephthalate whiskers. The preparation method of anhydrous calcium terephthalate whiskers includes the steps of subjecting ammonium terephthalate solution and calcium hydroxide slurry to reaction to obtain a precursor, and continuing the reaction at 120-150 DEG C in a high-pressure kettle for 1-6 h to obtain the anhydrous calcium terephthalate whiskers. The preparation method is green, low in cost and high in cleanliness level. The production process is free of three wastes, and the obtained anhydrous calcium terephthalate whiskers have large length-diameter ratio, high crystal strength and significant reinforcement effect. During the preparation of the calcium terephthalate whiskers from ammonium terephthalate and calcium hydroxide, isolated ammonia water may continue to dissolve terephthalic acid for next cycle or remaining water is also suitable for reuse after ammonia gas is recycled by means of ammonia steaming, and the whole process is free of three wastes and belongs to clean production.

Owner:JIANGSU ATE DONGTAI NEW MATERIALS TECH

A kind of method for making leather without tanning agent

ActiveCN113265493BContinuous and controlled removalHigh degree of cleanlinessPre-tanning chemical treatmentSpecial leather manufactureMolecular sieveOrganic solvent

The invention belongs to the technical field of leather making and discloses a method for making leather without tanning agents. First, the bare hide is dehydrated in a controlled manner using a molecular sieve-polar organic solvent composite dehydration medium. Subsequently, tanning agent-free leather is produced by increasing the surface roughness of the hide and reducing its surface energy. The present invention does not use any metal or non-metallic tanning agent, and has the advantage of being environmentally friendly; the present invention breaks the distribution balance of moisture between the bare hide and the polar organic solvent, and realizes the "from raw hide to polar organic solvent" for the moisture in the bare hide. Solvents, and then from polar organic solvents to molecular sieves" multi-media self-driven directional controllable dehydration, promotes continuous and controllable removal of moisture in raw hides, effectively solves the problem of low dehydration efficiency when pure polar organic solvents dehydrate bare hides, Many bath changes are required for dehydration, organic waste liquid is difficult to reuse, etc., and the molecular sieve-polar organic solvent dehydration system is easy to recover and can be used for multiple cycles for controllable dehydration of bare leather, providing a new clean system leather technology.

Owner:SICHUAN UNIV

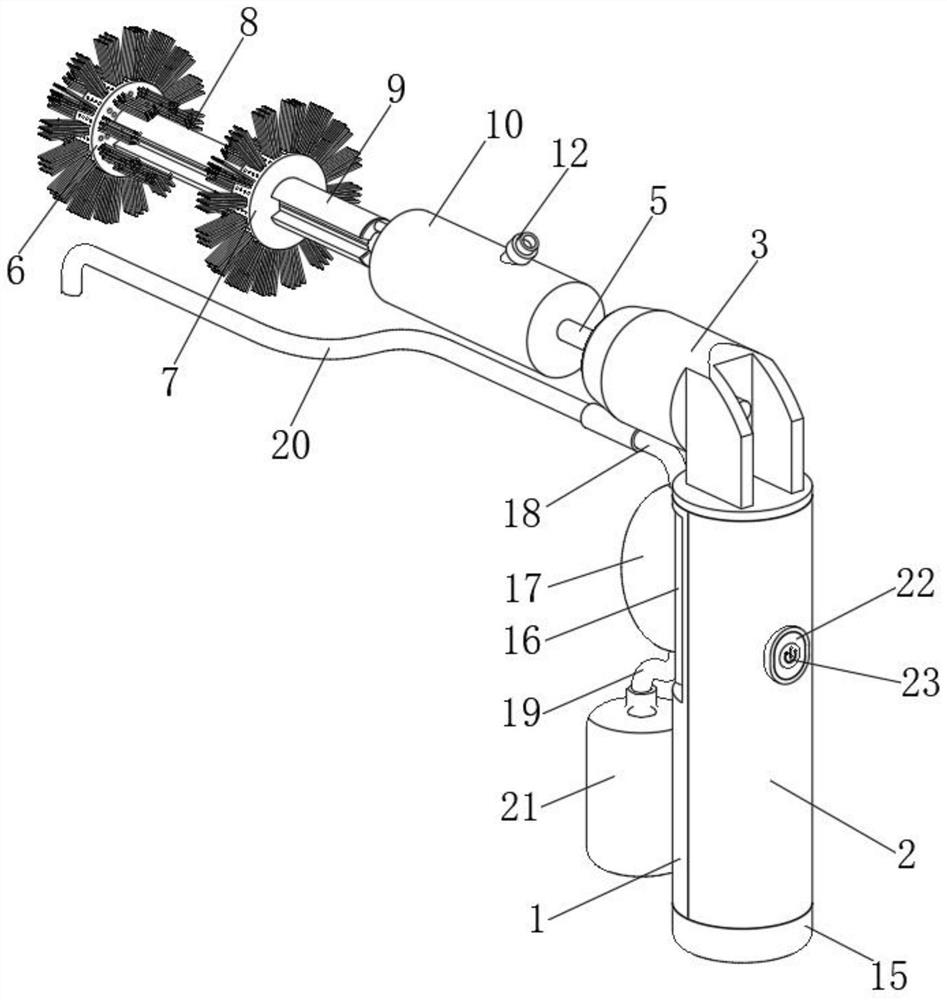

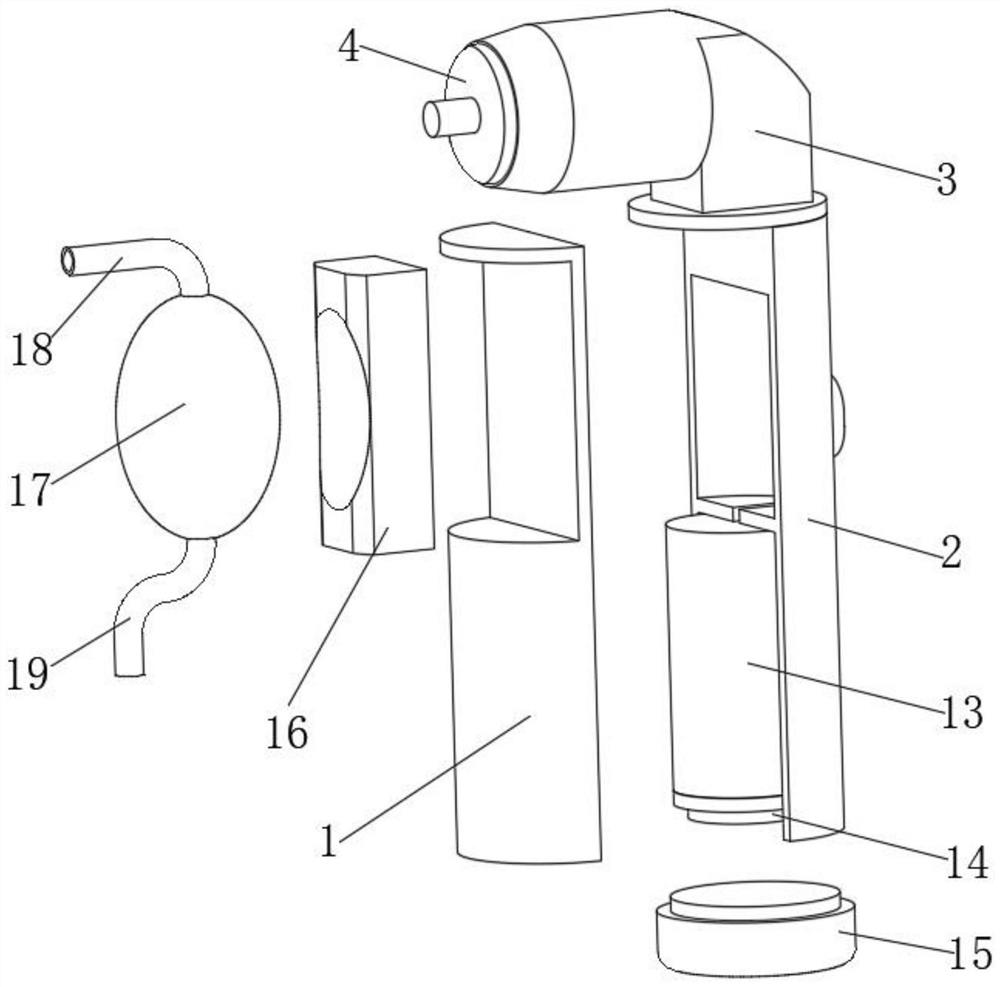

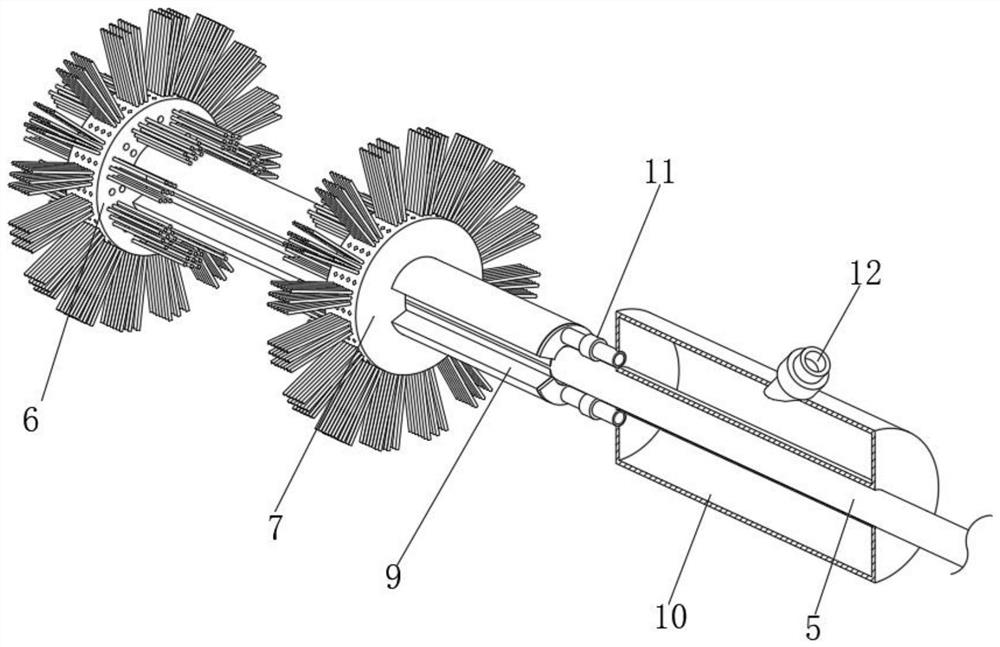

Electric nursing device for oral nursing of inpatient

The invention discloses an electric nursing device for oral nursing of inpatient, which comprises a first shell and a second shell, the second shell is mounted at the front end of the first shell, the second shell and the first shell jointly define a cylindrical structure, and a mounting seat is jointly mounted at the upper end of the first shell and the upper end of the second shell; a motor is fixedly inserted into the rear end of the mounting seat, the output end of the motor is in transmission connection with a rotating rod, the rear portion of the outer cylindrical surface of the rotating rod is fixedly sleeved with a first scrubbing mechanism and a second scrubbing mechanism, and the second scrubbing mechanism is located on the front side of the first scrubbing mechanism, and a first liquid conveying pipe is fixedly connected between the first scrubbing mechanism and the second scrubbing mechanism. The electric nursing device for oral nursing of the inpatient can meet the oral nursing requirement of a common inpatient, the oral nursing requirement of a severe inpatient and the oral nursing requirement of an unconscious patient, and is small in application limitation.

Owner:THE SECOND AFFILIATED HOSPITAL OF ANHUI MEDICAL UNIV

A method for producing low-odor clean automobile interior leather with biological enzyme technology

The invention relates to a method for producing low-odor and clean automotive interior leather by bio-enzyme technology, including fleshing, liming, deliming, softening and degreasing, pickling, tanning, retanning, dyeing, fatliquoring, drying, wrestling Softening, primer coating, middle coating, embossing, top coating and other steps. The present invention introduces a kind of biological enzyme to be used before raw hide pretreatment, tanning and retanning, which improves the efficiency of processes such as liming and depilation, degreasing and deodorization, and reduces the use of strong acids and alkalis, a large amount of surfactants and the generation of pollutants; At the same time, because the effect of degreasing treatment is strengthened, the protective effect on the leather fiber structure is obvious, and the problems such as loose surface of the product are improved. The leather obtained by using new technology and new materials is completely degreased, and the fiber interstitial removal effect is good, and the product has low odor. Low emission characteristics such as low fogging.

Owner:HAINING SENDE LEATHER +1

A kind of processing method of Guizhou Lixiang flat green tea

ActiveCN104255966BRealize automatic continuous processing and productionHigh degree of cleanlinessPre-extraction tea treatmentGreen teaComputer science

The invention relates to a processing method of green tea, in particular to a processing method of Guizhou Lixiang flat green tea, comprising the following steps: ① green tea withering; ⑤ Step-by-step drying; ⑥ Sieving; ⑦ Titian. The Guizhou Lixiang flat-shaped green tea produced by the method of the invention has a flat, straight and even appearance, emerald green color, long-lasting fragrance, and fresh, mellow and sweet aftertaste. Realized Guizhou Lixiang flat green tea scale, automatic continuous processing and production, high degree of cleanliness, greatly reduced labor intensity, improved production efficiency, reduced production cost, and improved product quality.

Owner:GUIZHOU TEA RES INST +1

A glass vertical transfer to horizontal transfer device

InactiveCN103570235BAchieve movementSimple structureGlass transportation apparatusBall screwEngineering

The invention relates to a glass vertical conveying to horizontal conveying device which comprises a conveying unit enabling glass to vertically move, an overturning unit enabling glass to be conveyed in a horizontal direction from a vertical direction, and a moving unit enabling glass to move in a horizontal direction. An idler wheel assembly and a shaft assembly are arranged on the conveying unit, a shaft driven by a servo motor is arranged on the overturning unit, a shaft base connected with the conveying unit is fixedly arranged on the shaft, and the moving unit is provided with a ball screw pair and a linear sliding rail so that the conveying unit on the moving unit moves along the linear sliding rail. The glass vertical conveying to horizontal conveying device is reasonable in design, simple in structure, convenient to operate, and stable and safe in conveying, also has the advantages of high transmission efficiency, little abrasion, accuracy in location, and the like, and is worthy of popularization.

Owner:NANJING PANDA ELECTRONICS +1

Method for preparing trifloxystrobin

InactiveCN101941921BRaw materials are cheap and easy to getHigh reaction yieldOximes preparationReaction stepOxalyl chloride

The invention discloses a method for preparing (E,E)-2-[1'-(3'-trifluoromethyl phenyl)-ethyl-imine-oxyl-tolyl]-2-carbonyl methyl acetate-O-ketoxime. The method comprises the following steps of: performing acylation reaction on toluene and methyl oxalyl chloride in the presence of anhydrous aluminum chloride to prepare 2-(2'-methyl phenyl)-2-carbonyl methyl acetate; reacting the 2-(2'-methyl phenyl)-2-carbonyl methyl acetate with methoxy amine hydrochloride to prepare (E)-2-(2'-methyl phenyl)-2-carbonyl methyl acetate-O-methyl ketoxime; and finally performing condensation reaction on the (E)-2-(2'-methyl phenyl)-2-carbonyl methyl acetate-O-methyl ketoxime and m-trifluoromethyl phenyl ethyl ketoxime under the action of alkaline substance to prepare the trifloxystrobin. The method has the advantages of a few reaction steps, simple synthesis process, readily available raw materials, mild reaction conditions, great industrial value and great social and economic benefit.

Owner:YUEYANG DIPU CHEM TECH

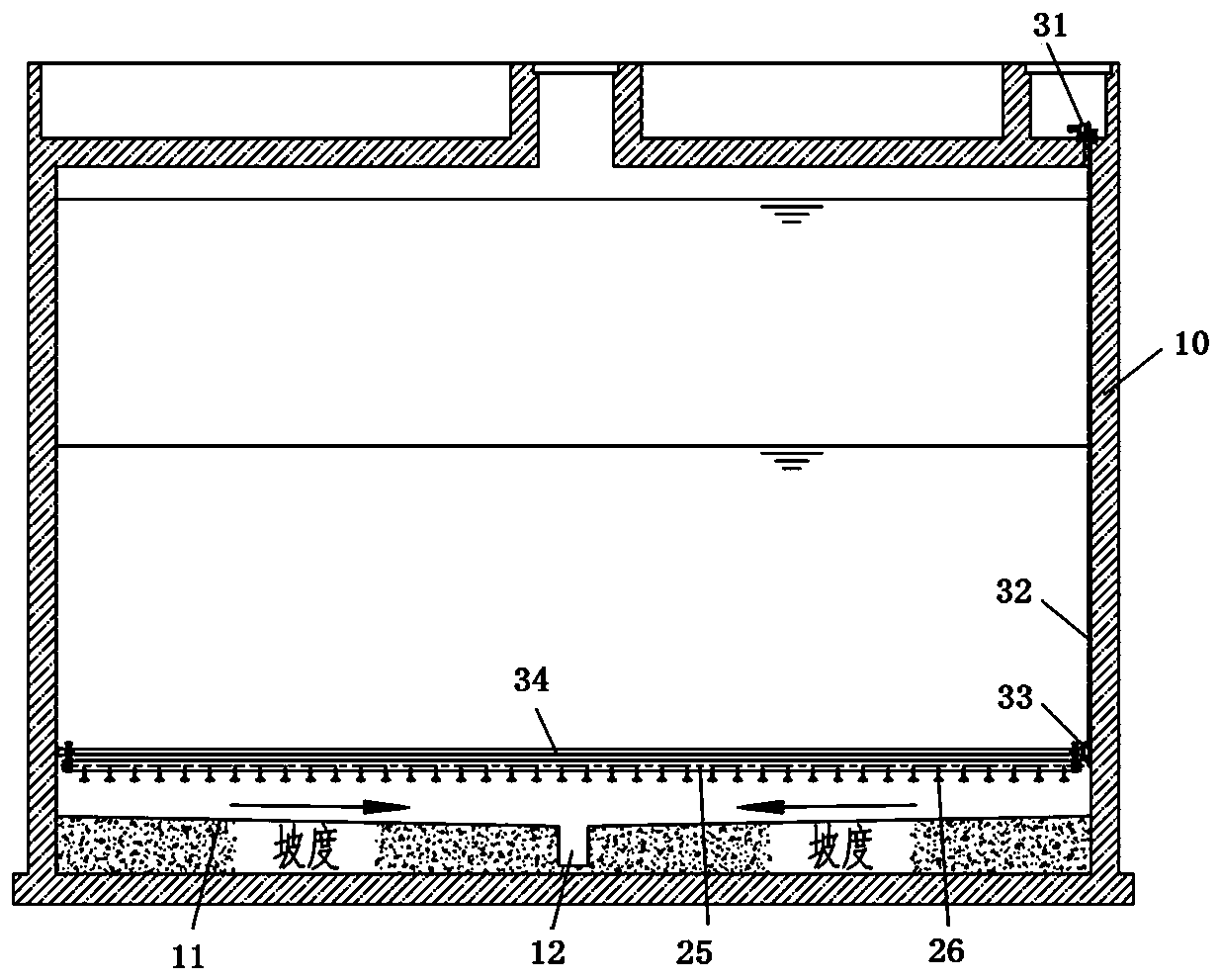

Coiling-sweeping type flushing device for regulating storage tank and control method thereof

PendingCN109183967AImprove reliabilityReduce maintenance costsSewerage structuresSewer cleaningSpray nozzleEngineering

The invention discloses a coiling-sweeping type flushing device for a regulating storage tank. The flushing device comprises a flushing moving mechanism which can be reciprocated along the storage tank length direction, a flushing water pipe which is fixed under the flushing moving mechanism and is movable along the length direction of the storage tank along with the flushing moving mechanism, anda plurality of nozzles which are arranged below the flushing water pipe, and a power pump which is arranged in the water collecting pit and is connected to the flushing water pipe through a connecting water pipe. By adjusting and fixing the arrangement distance and angle of the spray nozzles, the flushing device can cover the surface of the side gallery in an all-round way, can move back and forth, and the flushing water pressure is continuously strong, so that the surface of the gallery is flushed cleaner, and in addition, the flushing water can be recycled, thereby saving energy and environmental protection.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

A method for improving the performance of organic chrome-free tanned leather

The invention belongs to the technical field of leather processing and discloses a method for improving the performance of organic chrome-free tanned leather. The invention can effectively improve the color fastness, shrinkage temperature and physical sensory properties of finished leather through the organic synergy of tanning agents, dyeing and finishing materials and processes, and produce high-performance leather. The invention does not use formaldehyde-containing and chromium-containing leather chemical materials in the whole production process. Therefore, compared with the existing leather production technology based on chrome tanning, the present invention can completely eliminate chrome pollution, has a higher degree of cleaning, and is more friendly to the environment; Compared with the traditional leather production method, the leather produced by it does not contain formaldehyde and chromium, and its physical properties are obviously better, so it has higher market application value.

Owner:CHINA LEATHER & FOOTWEAR IND RES INST +1

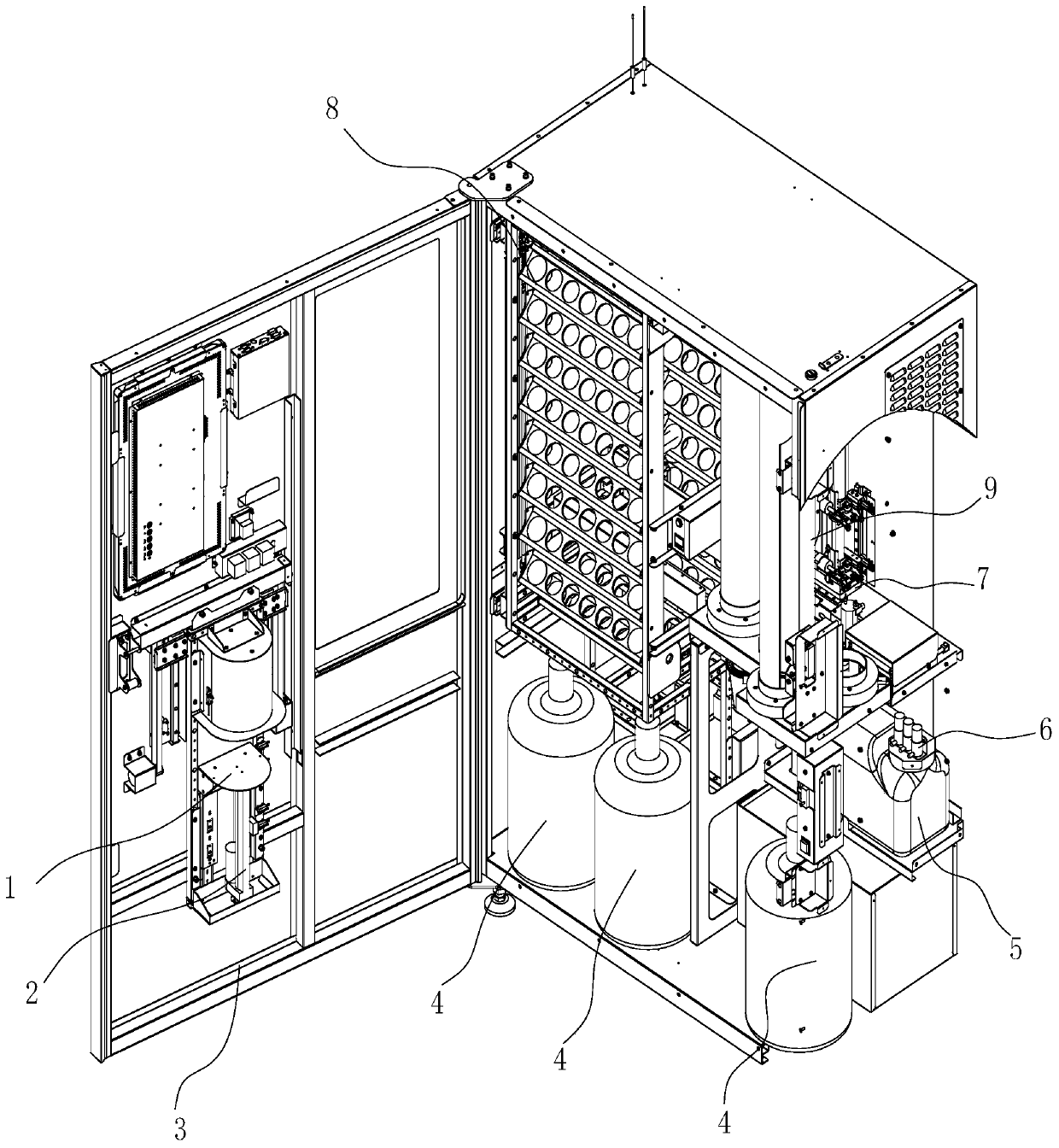

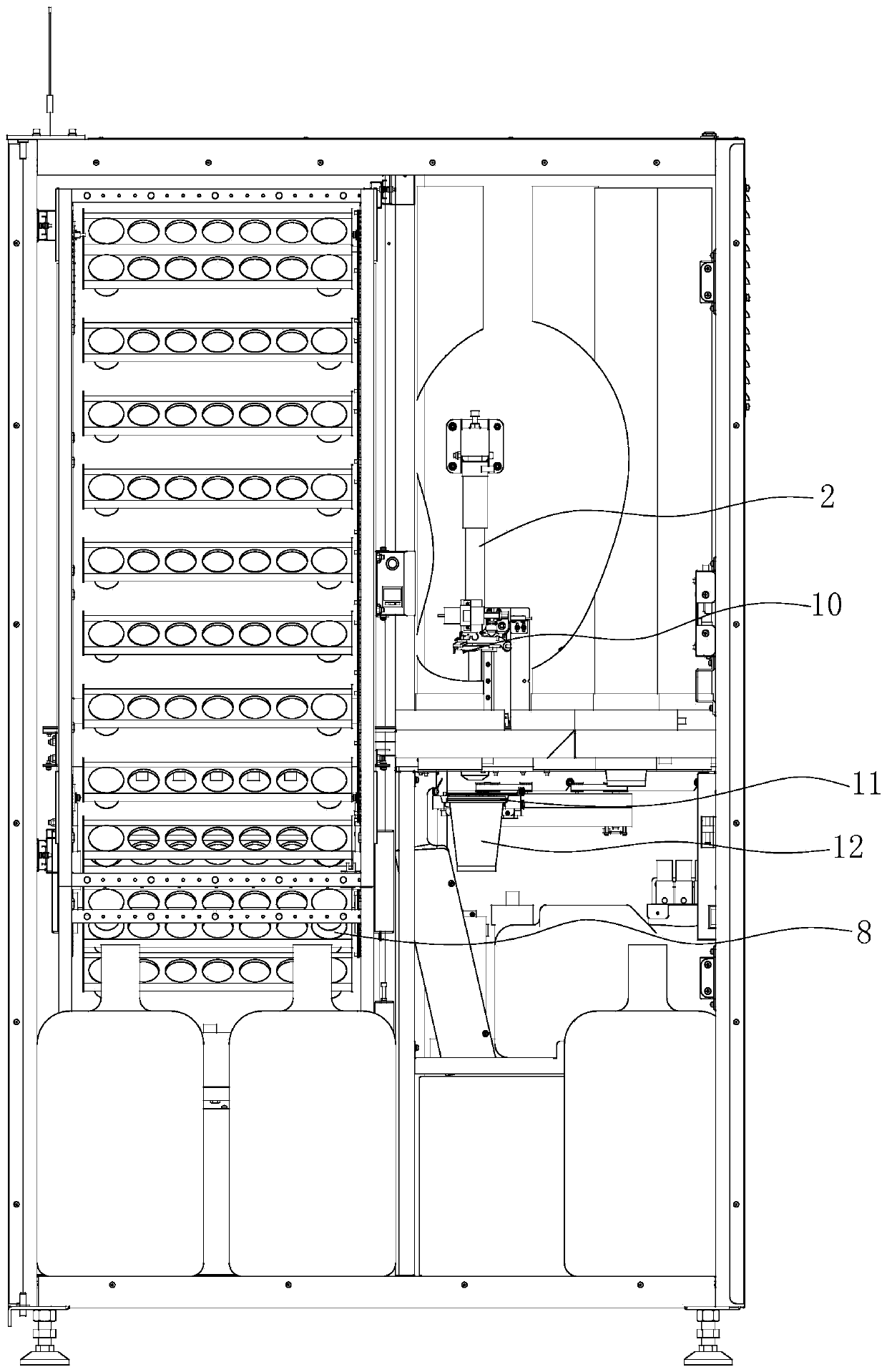

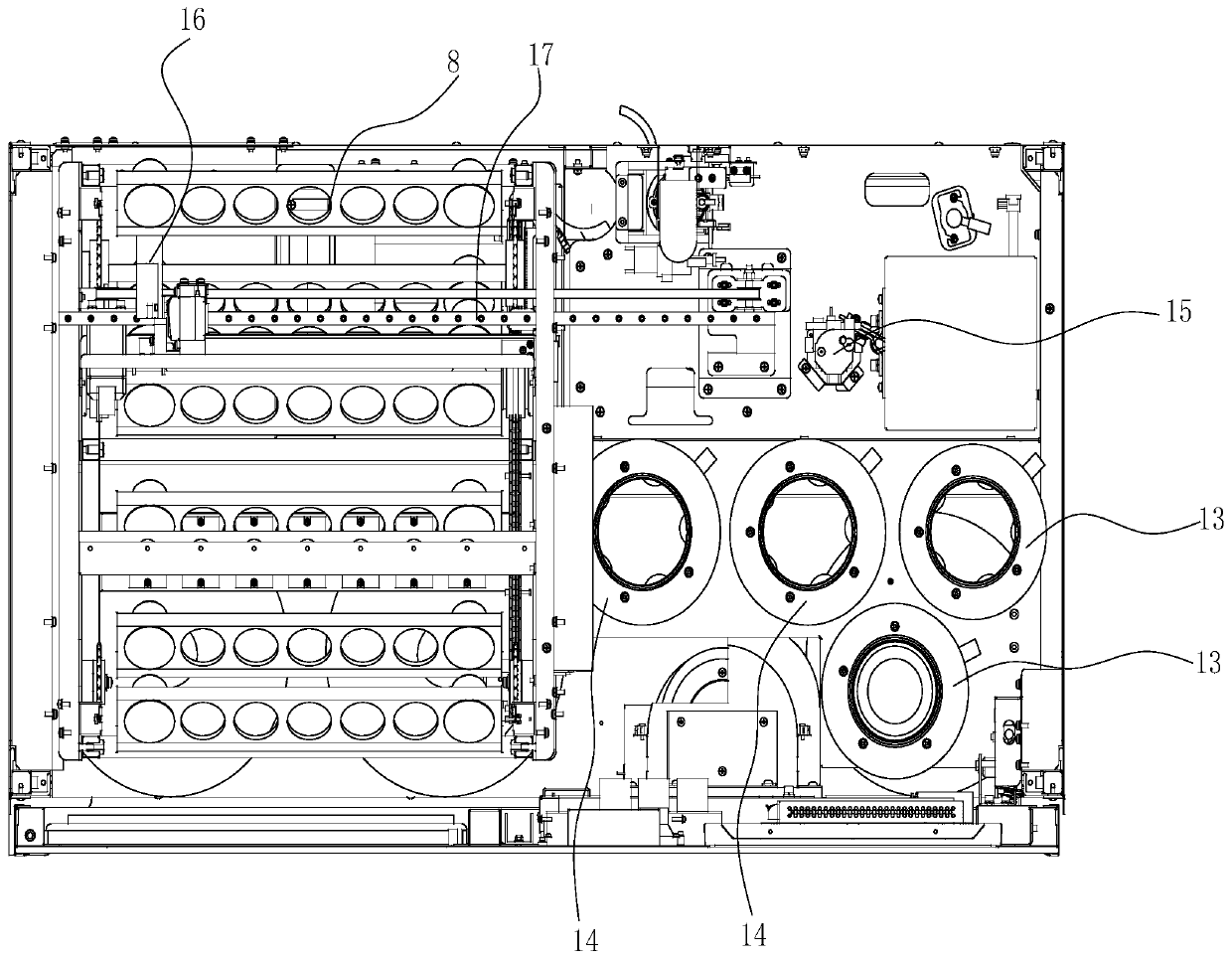

Capsule beverage vending machine

PendingCN110718019AHigh degree of cleanlinessApparatus for dispensing fluids/granular materialsEngineeringMechanical engineering

The invention discloses a capsule beverage vending machine which comprises a framework, an extraction bottom mold and an extraction needle tube, wherein the extraction needle tube is directly or indirectly and movably arranged at one side of the extraction bottom mold; the extraction bottom mold is directly or indirectly arranged on the framework; the capsule beverage vending machine also comprises a cargo disc, a suction disc, a moving ascending and descending mechanism and a driving mechanism; the cargo disc is directly or indirectly arranged in the framework; the moving ascending and descending mechanism is directly or indirectly and glidingly arranged in the framework, and is used for driving the cargo disc to move in the framework; the driving mechanism is arranged in the framework; the suction disc is arranged on the driving mechanism; the cargo disc is used for accommodating capsule solutes; and the suction disc is used for moving the capsule solutes from the cargo disc onto theextraction bottom mold. The capsule beverage vending machine has the following beneficial effects that a soft diaphragm of the capsule solutes can be automatically pierced, inside capsule solute particles are dissolved and flushed away, and manual brewing by labors is not needed; convenience and high speed are realized; and the brewing cleanness degree is high.

Owner:浙江嘉丰机电有限公司

A system for producing multiple water-soluble organic carbon fertilizers using vegetable waste

ActiveCN105272428BKill completelySimple structureBio-organic fraction processingOrganic fertiliser preparationTemperature controlAir filter

The present invention relates to a system using vegetable waste for production of a multi-component water soluble organic carbon fertilizer, the system includes a slag liquid separation system and a fermentation preparation system; the slag liquid separation system is provided with a liquid outlet, and the liquid outlet is connected with a liquid inlet of the fermentation preparation system. The slag liquid separation system comprises a juice collection bucket with the liquid outlet, a filter sieve and a pressing screw; the filter sieve is installed at the upper opening end of the juice collection bucket, and the screw pitch of the pressing screw located above the filter sieve is gradually reduced from a feeding port to a slag discharge port of the slag liquid separation system. The fermentation preparation system comprises a liner, a temperature control jacket for sleeving the liner, a stirrer, a mixer, and a sterile air filter in connection with the liner. The system can cleanly use the vegetable waste, can convert the vegetable waste into the fertilizer, has the characteristics of being high in degree of cleaning, thorough in killing of pathogenic bacteria, environmentally-friendly, and pollution-free, and belongs to the technical field of agricultural waste recycling and environmentally-friendly devices.

Owner:INST OF AGRI RESOURCES & ENVIRONMENT GUANGDONG ACADEMY OF AGRI SCI

A clean preparation method of submicron calcium terephthalate

ActiveCN105967999BHigh degree of cleanlinessReduce environmental costsOrganic compound preparationCarboxylic acid salt preparationCalcium hydroxideEvaporation

The invention discloses a clean preparation method of submicron calcium terephthalate. The preparation method comprises the following steps: a calcium hydroxide slurry with a multihole nozzle is introduced from the upper end, and an ammonium terephthalate solution with a dispersion modifier is introduced through the side surface of a high-speed centrifugal atomizer; the calcium hydroxide slurry and ammonium terephthalate solution are sufficiently mixed in a mixing chamber of a jet reactor, and enter a closed tank reactor via a diffuser chamber; and the materials are heated to the specified temperature while stirring to continue react for some time, thereby obtaining the calcium terephthalate. The method is green and environment-friendly, has high clean degree, and does not generate three wastes in the preparation process; and the obtained product is submicron particles. In the submicron calcium terephthalate preparation process, the separated ammonia water can continue dissolving terephthalic acid to enter the next circulation, or after ammonia gas is recovered by an ammonia evaporation technique, the residual water can be recycled, so the whole process does not generate three wastes and belongs to clean production.

Owner:JIANGSU ATE DONGTAI NEW MATERIALS TECH

Vanadium extraction method of sodium-modified vanadium extraction tailings

ActiveCN112095024AHigh degree of cleanlinessReduce manufacturing costProcess efficiency improvementThermal reactionHydrothermal reaction

The invention relates to the technical field of chemical engineering and resource comprehensive utilization, and discloses a vanadium extraction method of sodium-modified vanadium extraction tailings.The vanadium extraction method comprises the following steps that (1), magnesium oxide powder or magnesium hydroxide fine powder and an optional leaching aid are added into the sodium-modified vanadium extraction tailings, then water is added, mixing and ball-milling are carried out to form a homogeneous slurry; (2), the slurry is put into a high-pressure reaction kettle for hydrothermal reaction; and (3), filtering is carried out after reaction is completed to obtain a vanadium-containing solution and vanadium extraction residues. According to the vanadium extraction method of the sodium-modified vanadium extraction tailings, a full-wet hydrothermal extraction process is adopted, no waste gas is generated, the cleanliness degree is high, and the method is environmentally friendly; compared with a traditional pyrogenic process, the method is low in production cost, the maximum leaching rate of vanadium in the sodium-modified vanadium extraction tailings can reach 69%, a large amount of vanadium can be recycled, and good economic benefits and social benefits are achieved; and the method is simple and feasible in technological operation, and vanadium flakes with the grade being 98%or above can be obtained after the vanadium-containing solution is concentrated and subjected to vanadium precipitation.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com