Brand new recycled part production line

A production line, a new technology, applied in the field of printing consumables production equipment, can solve problems such as improper assembly, scrapped consumables, and damaged accessories, and achieve the effects of avoiding mess, installing high-quality products, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

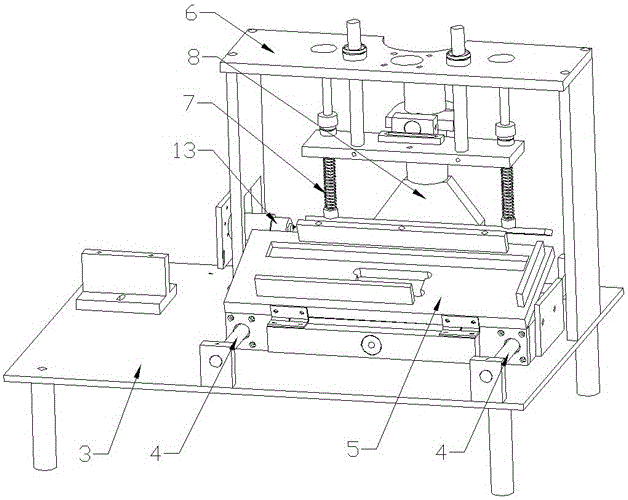

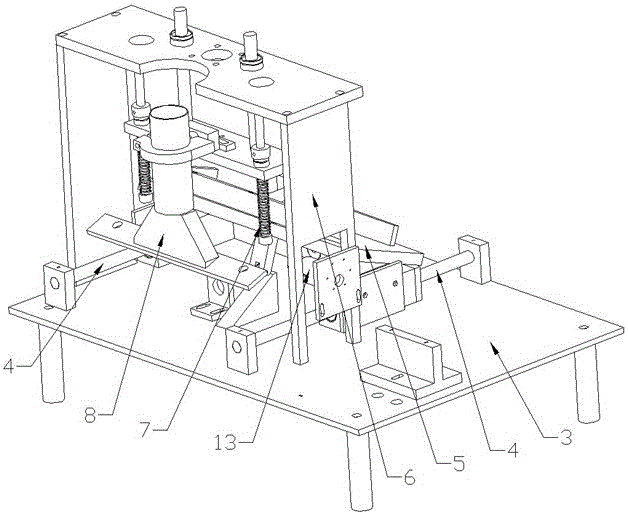

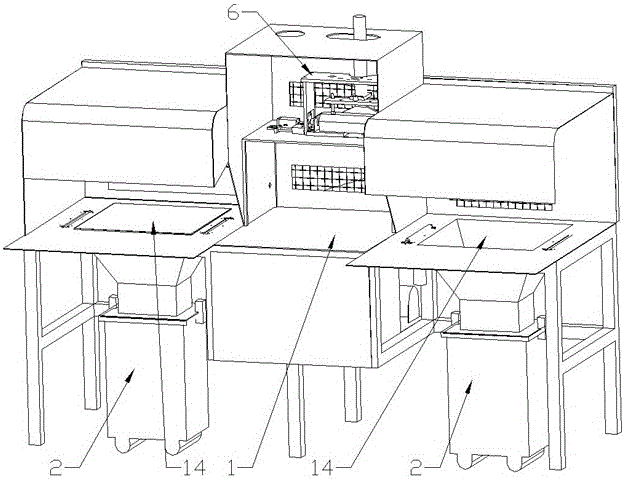

[0019] like Figure 1 to Figure 6 As shown, the production line includes a dismantling workstation and an installation line, and the workstation is arranged on one side of the installation line. The dismantling workstation includes a machine platform 1 on which a waste powder removal device and a waste powder collection bucket 2 are arranged. The waste powder removal device is connected with the peripheral suction machine, and the waste powder removal device includes a bottom plate 3, a double guide rod 4 arranged on the bottom plate 3, a sliding sleeve on the double guide rod 4 The powder box fixing groove 5, the bracket 6 arranged on the bottom plate 3, the pressure column 7 arranged on the bracket 6 and above the powder box fixing groove 5, and the rear side of the powder box fixing groove 5 The waste toner suction pipe 8 is provided with a first cylinder on the rear side of the bottom plate 3, the output shaft of the first cylinder is connected to the powder box fixing gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com