A clean preparation method of submicron calcium terephthalate

A technology of calcium terephthalate and ammonium terephthalate, which is applied in the chemical field, can solve the problems of environmental pollution, lack, and no clear particle size of calcium terephthalate, and achieve a high degree of cleanliness and reduced environmental protection costs , the effect of huge potential economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

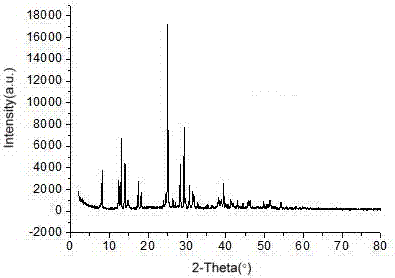

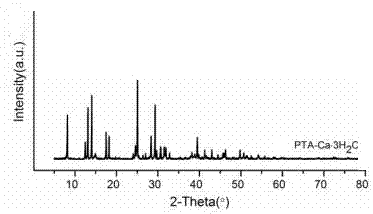

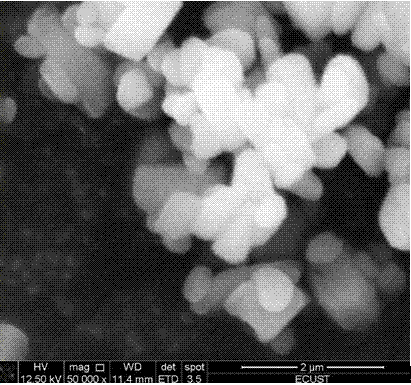

[0023] A clean preparation method of submicron calcium terephthalate of the present invention comprises the following steps: introducing the calcium hydroxide slurry from the upper end of the jet reactor with a porous nozzle, and pre-adding the parabenzene The ammonium diformate solution is introduced from the side of the jet reactor through a high-speed centrifugal atomizer. After the two are fully mixed in the mixing chamber of the jet reactor, they leave the jet reactor through the diffusion chamber and then enter the closed tank reactor. , heating the material to the specified temperature while stirring, continue to mix and react for a certain period of time, and finally separate, wash, and dry at a temperature not higher than 100°C to obtain calcium terephthalate trihydrate.

[0024] The calcium hydroxide slurry is obtained by dissolving and dispersing solid calcium hydroxide in hot water at 40° C., and the mass percent concentration of the calcium hydroxide slurry is 5%. ...

Embodiment 2

[0034] The difference between embodiment 2 and embodiment 1 is:

[0035] The calcium hydroxide slurry is obtained by dissolving and dispersing solid calcium hydroxide in hot water at 90° C., and the mass percent concentration of the calcium hydroxide slurry is 25%.

[0036] In the ammonium terephthalate solution added with sodium hexametaphosphate, the mass percent concentration of ammonium terephthalate is 15%. The ammonium terephthalate solution is prepared by dissolving terephthalic acid in ammonia solution, or directly dissolving commercially available ammonium terephthalate solid in water, and its mass percent concentration is 15%. The quality of sodium hexametaphosphate is 3.5% of the quality of generated calcium terephthalate.

[0037] The specified temperature is 80°C.

[0038] The specified time is 24 hours.

[0039] The reaction molar ratio of described calcium hydroxide and ammonium terephthalate is 1.1: 1.

[0040] Figure 4 The particle size distribution curv...

Embodiment 3

[0042] The difference between embodiment 3 and embodiment 1 is:

[0043]The calcium hydroxide slurry is obtained by dissolving and dispersing solid calcium hydroxide in hot water at 75° C., and the mass percent concentration of the calcium hydroxide slurry is 20%.

[0044] In the ammonium terephthalate solution added with sodium polyacrylate, the mass percent concentration of ammonium terephthalate is 9%. The ammonium terephthalate solution is prepared by dissolving terephthalic acid in ammonia solution, or directly dissolving commercially available ammonium terephthalate solid in water, and its mass percent concentration is 9%. The quality of sodium polyacrylate is 2% of the quality of generated calcium terephthalate.

[0045] The specified temperature is 70°C.

[0046] Said certain time is 12h.

[0047] The reaction molar ratio of described calcium hydroxide and ammonium terephthalate is 1.0: 1.

[0048] Figure 4 The particle size distribution curve in shows that the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com