High-temperature soft-melted steel slag precise control high-efficiency cleaning crushing treatment device and method

A technology for precise control and processing devices, applied in chemical instruments and methods, combined devices, separation methods, etc., can solve problems such as large index fluctuations, inability to collect smoke and dust as much as possible, and affect the efficiency of steel slag processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

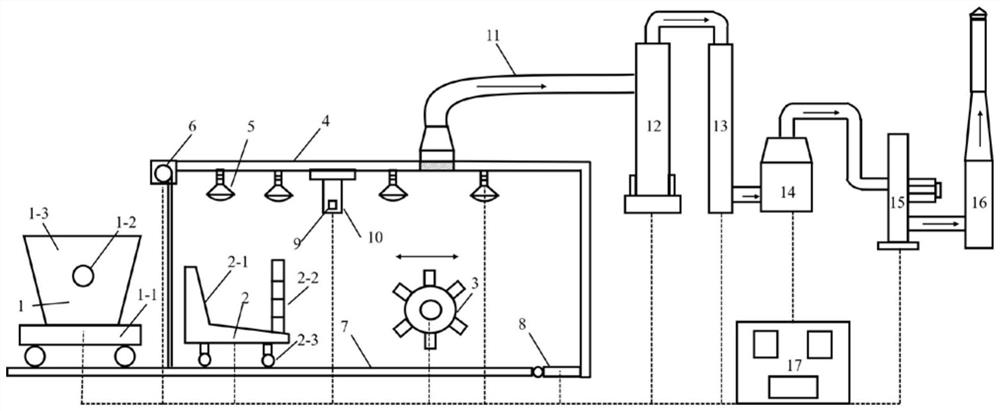

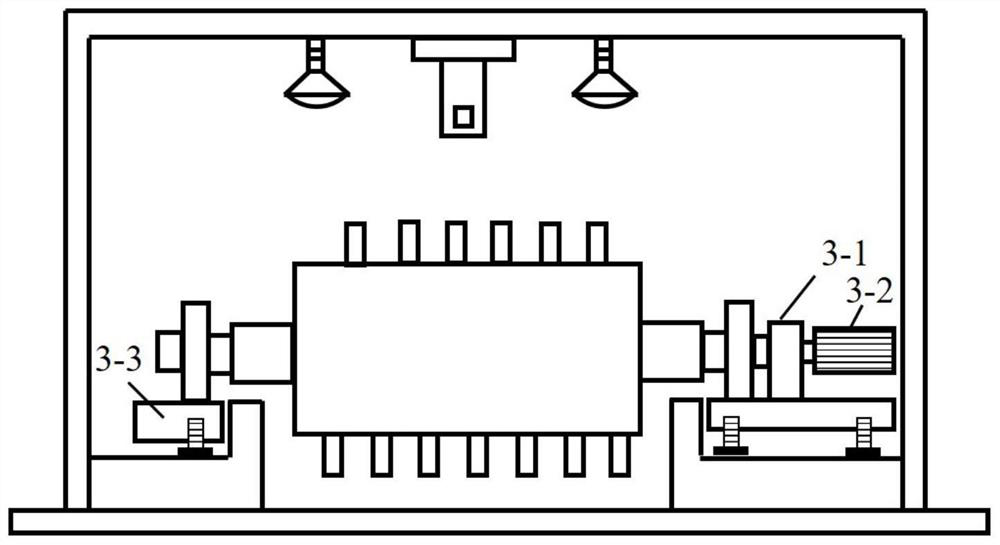

[0048] A high-temperature soft-melting steel slag precisely controlled efficient clean crushing treatment device such as figure 1 with figure 2As shown, the high-temperature soft-melting steel slag accurately controls the high-efficiency clean crushing treatment device including: mobile tank type slag feeder 1, bulk slag separation device 2, bidirectional rotary high temperature resistant crusher 3, fully enclosed airtight cover 4 , Automatic water fetching device 5, high temperature and wear-resistant hard crushing bed 7, precise temperature measurement system for steel slag, dust cleaning treatment system and intelligent monitoring operating system 17. The mobile tank type slag feeder 1 is placed outside the fully enclosed airtight cover 4; the bulk slag separation device 2 is placed inside the fully enclosed airtight cover 4, next to the slag outlet; the fully enclosed airtight cover 4 is located The top of the high-temperature wear-resistant hard crushing bed 7 is in clo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com