Method for processing Guizhou chestnut-fragrance flat green tea

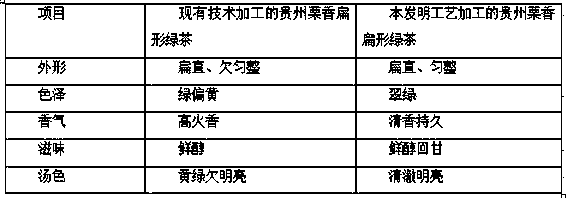

A flat green tea and processing method technology, applied in the field of green tea processing, can solve the problems of waste of processing equipment and human resources, uneven product quality, scattered processing links, etc., achieve flat and straight shape, improve production efficiency, and improve quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

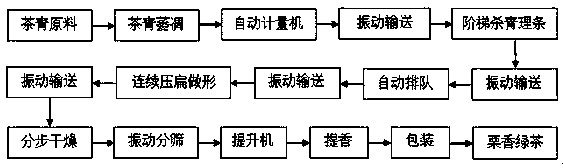

Method used

Image

Examples

Embodiment 1

[0018] A processing method of Guizhou chestnut-flavored flat green tea, comprising the steps of:

[0019] 1) Green tea withering: Spread the graded green tea in the withering tank with a thickness of 4 cm and a time of 6 hours, blowing natural wind twice in the middle, each blowing time is 30 minutes, and the moisture content of the green tea is 73%. The stalks of the tea green leaves are slightly soft, the grass smell disappears, and the fragrance is revealed;

[0020] 2) Ladder finishing and stripping: transport the moderately withered green tea greens evenly through the fresh leaf metering scale to the ladder finishing and stripping machine for finishing. The ladder finishing and stripping machines are equipped with automatic dehumidification devices. The amount of leaves thrown is 0.75 catties / min, the temperature for the first finishing is 170°C, and the time is 32s, and then it is automatically transported to the second finishing machine, and the temperature for the secon...

Embodiment 2

[0027] A processing method of Guizhou chestnut-flavored flat green tea, comprising the steps of:

[0028] 1) Green tea withering: Put the graded green tea in the withering tank, the thickness of the spread is 5cm, the spreading time is 9 hours, and the natural wind is blown 3 times in the middle, and the time of each blowing is 30 minutes. The moisture content of the green tea is 70%. The stalks of the tea green leaves are slightly soft, the grass smell disappears, and the fragrance is revealed;

[0029] 2) Ladder finishing and stripping: transport the moderately withered green tea greens evenly through the fresh leaf metering scale to the ladder finishing and stripping machine for finishing. The ladder finishing and stripping machines are equipped with automatic dehumidification devices. The amount of leaves thrown is 0.75 catties / min, the temperature for the first finishing is 160°C, and the time is 35s, and then it is automatically transported to the second finishing mac...

Embodiment 3

[0036] A processing method of Guizhou chestnut-flavored flat green tea, comprising the steps of:

[0037] 1) Green tea withering: Spread the graded green tea in the withering tank with a thickness of 3cm and a time of 4 hours, blowing natural wind for 3 times in the middle, each blowing time is 30 minutes, the moisture content of the green tea is 75%, The stalks of the tea green leaves are slightly soft, the grass smell disappears, and the fragrance is revealed;

[0038] 2) Ladder finishing and stripping: transport the moderately withered green tea to the ladder finishing and stripping machine evenly through the fresh leaf measuring scale, and carry out the finishing and stripping. The amount of leaves thrown is 0.75 catties / min, the temperature for the first finishing is 180°C, and the time is 30s, and then it is automatically transported to the second finishing machine, and the temperature for the second finishing is 100°C. It is 40s, and finally it is automatically transport...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com