A kind of preparation method and application of anhydrous calcium terephthalate whisker

A technology of calcium terephthalate and ammonium terephthalate, applied in the chemical field, can solve the problems of remarkable reinforcing performance of polymer materials, lack of terephthalic acid whiskers, and non-recyclable use, etc., and achieve remarkable reinforcing effect , huge potential economic benefits, and the effect of reducing environmental protection costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

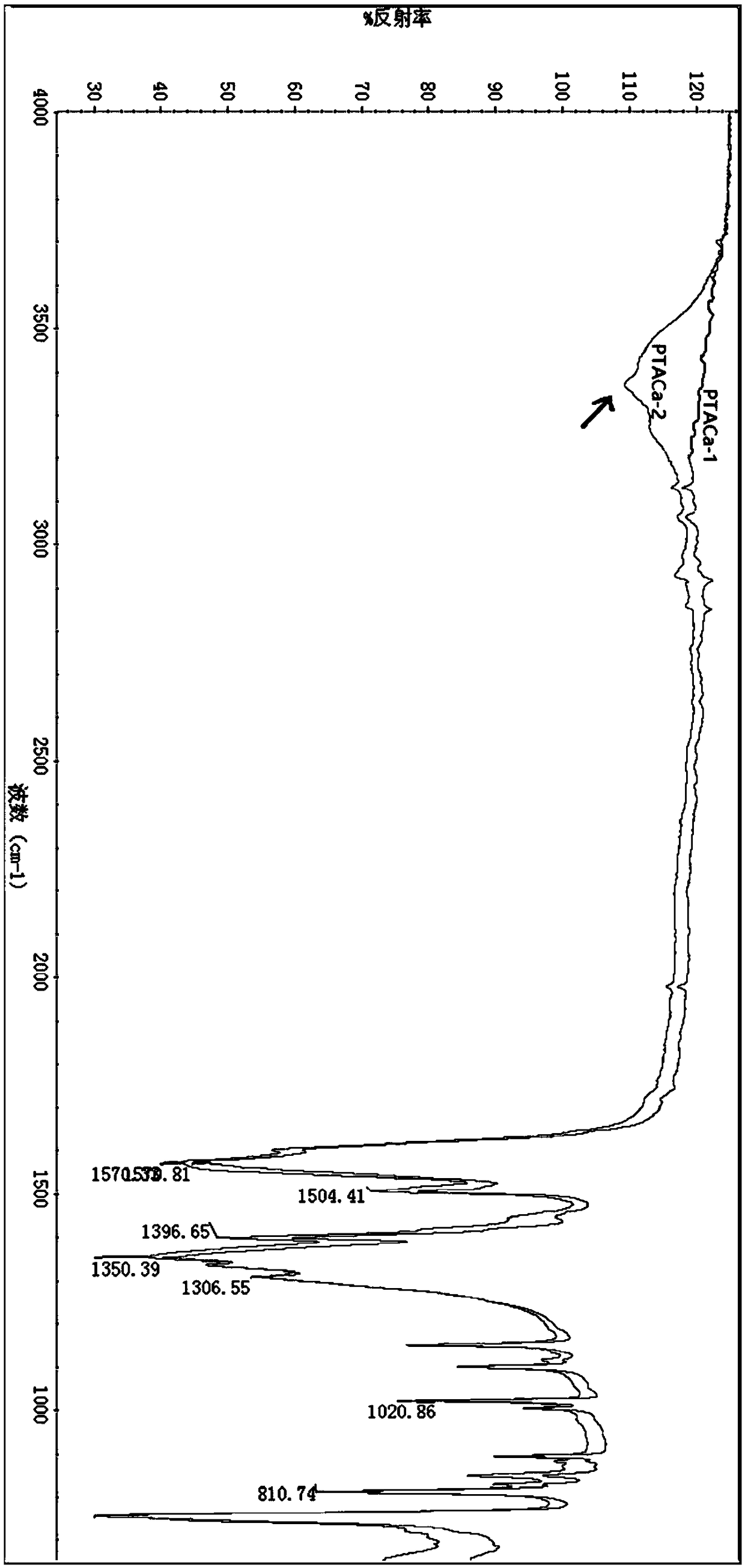

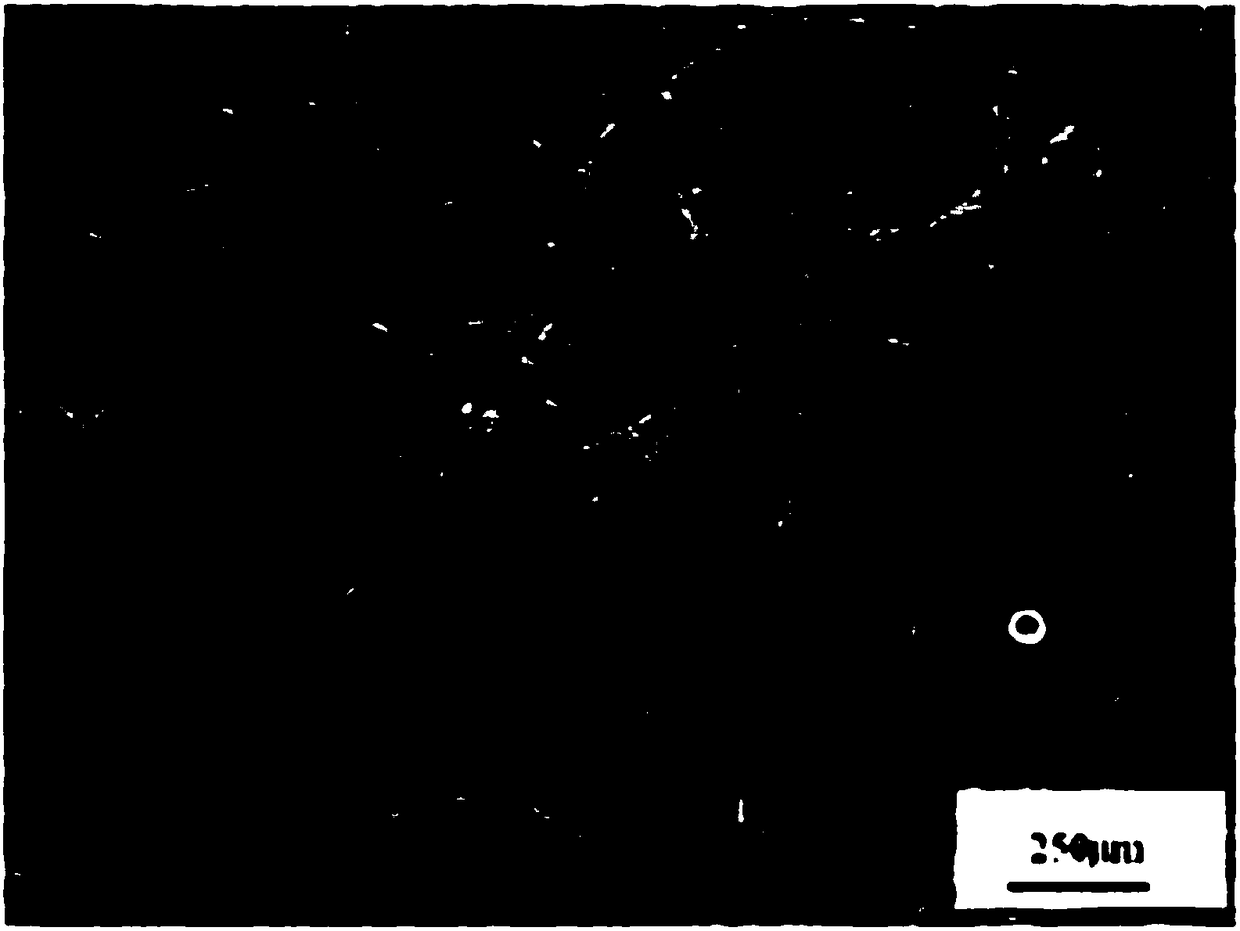

[0020] A method for preparing anhydrous calcium terephthalate whiskers of the present invention comprises the following steps: the precursor obtained by reacting ammonium terephthalate solution and calcium hydroxide slurry is continued in an autoclave at 120°C After reacting for 2 hours, anhydrous calcium terephthalate whiskers were obtained. The obtained anhydrous calcium terephthalate whiskers can be added to polymer materials as a reinforcing agent to prepare composite materials with high strength and high modulus.

[0021] The preparation method of the precursor is to slowly add the calcium hydroxide slurry to the ammonium terephthalate solution under constant stirring, and then continue the reaction for 5 minutes.

[0022] The mass percent concentration of the ammonium terephthalate solution is 2%. The ammonium terephthalate solution is prepared by dissolving terephthalic acid in ammonia solution, or directly dissolving commercially available ammonium terephthalate solid...

Embodiment 2

[0031] The difference between Example 2 and Example 1 is that a method for preparing anhydrous calcium terephthalate whiskers of the present invention comprises the following steps: the precursor obtained by reacting ammonium terephthalate solution and calcium hydroxide slurry , continue the reaction in an autoclave at 140° C. for 4 hours to obtain anhydrous calcium terephthalate whiskers. The obtained anhydrous calcium terephthalate whiskers can be added to polymer materials as a reinforcing agent to prepare composite materials with high strength and high modulus.

[0032] The mass percent concentration of the ammonium terephthalate solution is 10%. The ammonium terephthalate solution is prepared by dissolving terephthalic acid in ammonia solution, or directly dissolving commercially available ammonium terephthalate solid in water, and its mass percent concentration is 10%.

[0033] The calcium hydroxide slurry is obtained by dissolving and dispersing solid calcium hydroxide...

Embodiment 3

[0036] The difference between Example 3 and Example 1 is that a method for preparing anhydrous calcium terephthalate whiskers of the present invention comprises the following steps: the precursor obtained by reacting ammonium terephthalate solution and calcium hydroxide slurry , continue the reaction in an autoclave at 150° C. for 6 h to obtain anhydrous calcium terephthalate whiskers.

[0037] The mass percent concentration of the ammonium terephthalate solution is 15%. The ammonium terephthalate solution is prepared by dissolving terephthalic acid in ammonia solution, or directly dissolving commercially available ammonium terephthalate solid in water, and its mass percent concentration is 15%.

[0038]The calcium hydroxide slurry is obtained by dissolving and dispersing solid calcium hydroxide in hot water at 90° C., and the mass percent concentration of the calcium hydroxide slurry is 25%.

[0039] The reaction molar ratio of the calcium hydroxide to the ammonium terephtha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com