A method for dry transformation of gypsum whiskers

A gypsum whisker and transformation technology, which is applied in the field of gypsum whisker dry transformation technology, can solve the problems of long time consumption, low quality stability, high production equipment requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

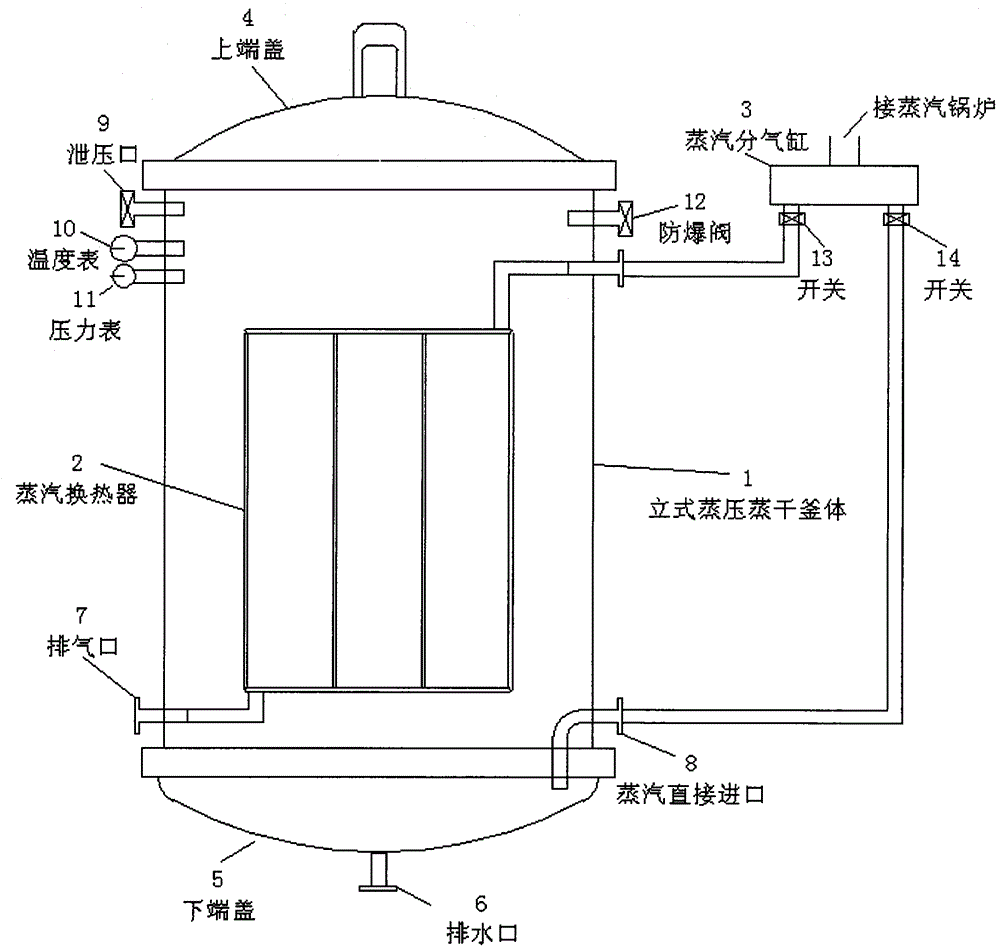

[0015] As shown in the figure, the lower end cover 5 of the autoclave 1 is sealed, and the gypsum whiskers are packed into the autoclave 1, preferably without the steam heat exchanger 2;

[0016] Seal the upper end cover 4 of the autoclaved steaming kettle 1, close the pressure relief port 9 on the kettle body and the drain port 6 of the lower end cover, and slightly open the exhaust port 7;

[0017] Simultaneously open the switch 13 and the switch 14 leading to the steam heat exchanger and the direct steam inlet on the steam sub-cylinder 3, and feed in steam at 130°C;

[0018] When the temperature displayed by the thermometer 10 in the autoclave 1 reaches 60° C., turn off the switch 14;

[0019] When the temperature displayed by the temperature gauge 10 in the autoclave 1 reaches 120°C and the pressure displayed by the pressure gauge 11 reaches 0.2MPa-0.5MPa, the switch 13 is turned off;

[0020] After heat preservation and pressure holding for 3-6 hours, open the pressure r...

Embodiment 2

[0024] As shown in the figure, the lower end cover 5 of the autoclave 1 is sealed, and the gypsum whiskers are put into the autoclave 1, preferably to cover the steam heat exchanger 2;

[0025] Seal the upper end cover 4 of the autoclaved steaming kettle 1, close the pressure relief port 9 on the kettle body and the drain port 6 of the lower end cover, and slightly open the exhaust port 7;

[0026] Simultaneously open the switch 13 and the switch 14 leading to the steam heat exchanger and the direct steam inlet on the steam sub-cylinder 3, and feed steam at 150°C;

[0027] When the temperature displayed by the temperature gauge 10 in the autoclave 1 reaches 80°C-90°C, turn off the switch 14;

[0028] When the temperature displayed by the temperature gauge 10 in the autoclave 1 reaches 120°C-150°C, and the pressure displayed by the pressure gauge 11 reaches 0.2MPa-0.3MPa, the switch 13 is turned off;

[0029] After heat preservation and pressure holding for 3-6 hours, open the...

Embodiment 3

[0033] As shown in the figure, the lower end cover 5 of the autoclave 1 is sealed, and the gypsum whiskers are packed into the autoclave 1, preferably without the steam heat exchanger 2;

[0034] Seal the upper end cover 4 of the autoclaved steaming kettle 1, close the pressure relief port 9 on the kettle body and the drain port 6 of the lower end cover, and slightly open the exhaust port 7;

[0035] Simultaneously open the switch 13 and the switch 14 leading to the steam heat exchanger and the direct steam inlet on the steam sub-cylinder 3, and feed in steam at 190°C;

[0036] When the temperature displayed by the temperature gauge 10 in the autoclave 1 reaches 100° C., turn off the switch 14;

[0037] When the temperature displayed by the temperature gauge 10 in the autoclave 1 reaches 150°C and the pressure displayed by the pressure gauge 11 reaches 0.3MPa-0.5MPa, the switch 13 is turned off;

[0038] After heat preservation and pressure holding for 3-6 hours, open the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com