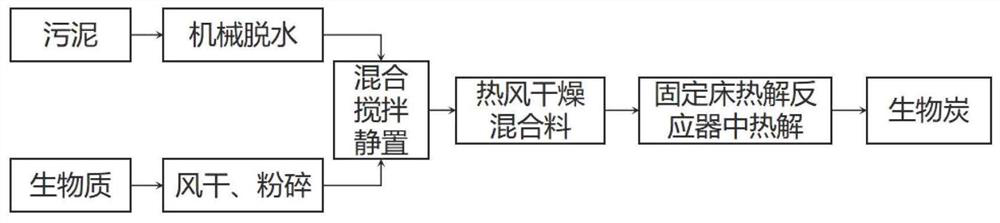

Method for preparing biochar and solidifying heavy metals through coupling sludge with biomass pyrolysis

A biomass pyrolysis and biochar technology, which is applied to chemical instruments and methods, water pollutants, sludge treatment, etc., can solve the problems of poor sludge charcoal quality, unsatisfactory heavy metal solidification effect, etc., achieve low ash content, reduce Effects of heavy metal pollution and high oil yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The rice rod is selected as a biomass sample, and the rice rod is dried in an oven at 105 ° C for 10 hours before mixing with industrial sludge, wherein the rice rod is broken and sieved from 0.15-0.35 mm particle diameter;

[0036] Dehydration treatment of industrial sludge is reduced from 80% to less than 60%, and rice is mixed with sludge with sludge in mass mixing ratios 1: 1, and mixed heavy metal sludge and biomass mixture The mixture was stirred with a mixer for 4 h and allowed to stand at room temperature for 8 hours;

[0037] The retained heavy industrial sludge with the biomass mixture was dried in an electric blast drying tank at 105 ° C for 24 hours to obtain a sludge-biomass mixture;

[0038] The dry sludge-biomass mixed feed is added to the quartz boat. The pyrolysis is added to the fixed bed tube furnace reactor. It is introduced into nitrogen as a protective atmosphere, and the temperature rise rate is 10 ° C / min, and the temperature is increased to 500 ° ...

Embodiment 2

[0044] The rice rod is selected as a biomass sample, and the rice rod is dried in an oven at 105 ° C for 10 hours before mixing with industrial sludge, wherein the rice rod is broken and sieved from 0.15-0.35 mm particle diameter;

[0045] Dehydration treatment of industrial sludge is reduced from 80% to less than 50%, mixed with sludge with sludge in mass mixing ratios 1: 0.5, mixed heavy metal sludge and biomass mixture The mixture was stirred with a mixer for 2 h and allowed to stand at room temperature for 5 hours;

[0046] The retained heavy industrial sludge with the biomass mixture was dried in an electric blast drying tank at 105 ° C for 24 hours to obtain a sludge-biomass mixture;

[0047] The dry sludge-biomass mixed feed is added to the quartz boo bots in the fixed bed tube furnace reactor, and the nitrogen is introduced as the protective atmosphere, the temperature rise rate is 15 ° C / min, and the temperature is increased to 600 ° C, After holding up 60 min, the hot ...

Embodiment 3

[0049] The rice rod is selected as a biomass sample, and the rice rod is dried in an oven at 105 ° C for 10 hours before mixing with industrial sludge, wherein the rice rod is broken and sieved from 0.15-0.35 mm particle diameter;

[0050] Dehydration treatment of industrial sludge is reduced from 80% to less than 65%, and the rice rod and sludge of mass mixing ratio 1: 2 are mixed, and mixed heavy metal sludge and biomass mixture The mixture was stirred with a mixer for 5 h and allowed for 10 hours at room temperature;

[0051] The retained heavy industrial sludge with the biomass mixture was dried in an electric blast drying tank at 105 ° C for 24 hours to obtain a sludge-biomass mixture;

[0052] The dry sludge-biomass mixed material is packed in quartz boat furnace reactor, and nitrogen is introduced into the protective atmosphere, and the temperature rise rate is 20 ° C / min, and then the temperature is increased to 700 ° C, After holding up 60 min, the hot solution is obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com