Biological oil phase-division upgrading method and device

A bio-oil, oil-soluble technology, applied in the petroleum industry, hydrocarbon oil treatment, hydrotreating process, etc., can solve problems such as inability to remove or convert sugar compounds, inability to fundamentally solve the problem of polymerization and coking, corrosion, etc. Coking problem, low moisture content, high calorific value effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

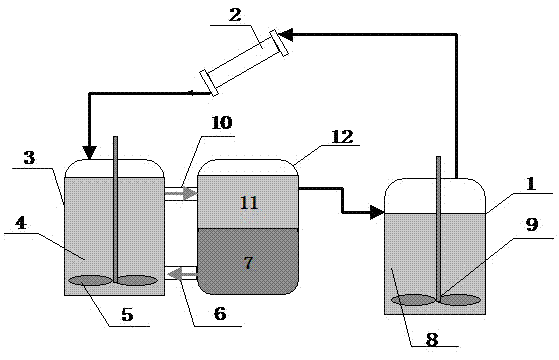

Method used

Image

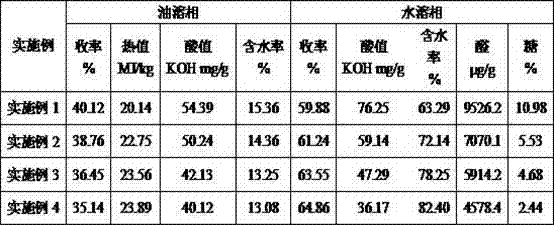

Examples

Embodiment 1

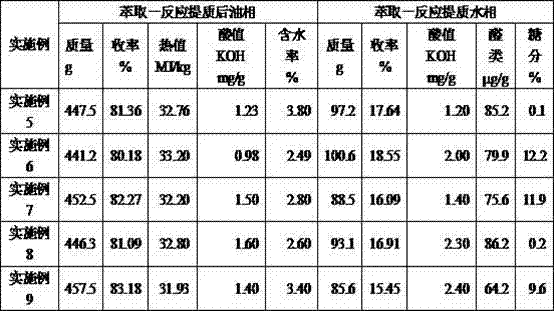

[0039] Put 200 g of bio-oil in a 500 mL flask, then add 60 g of water (the mass ratio of bio-oil / water is 1:0.3) under the action of mechanical stirring, stir and extract at room temperature for half an hour, transfer to 500 mL In the liquid funnel, 179.76 g of water-soluble phase (upper layer) and 80.24 g of oil-soluble phase (lower layer) were obtained. See Table 2 for other indicators of oil-soluble phase and water-soluble phase.

Embodiment 2

[0041] Put 200 g of bio-oil in a 500 mL flask, then add 120 g of water (the mass ratio of bio-oil / water is 1:0.6) under mechanical stirring, stir and extract at room temperature for half an hour, transfer to 500 mL In the liquid funnel, 242.48 g of water-soluble phase (upper layer) and 77.52 g of oil-soluble phase (lower layer) were obtained. See Table 2 for other indicators of oil-soluble phase and water-soluble phase.

Embodiment 3

[0043] Put 200 g of bio-oil in a 500 mL flask, then add 200 g of water (the mass ratio of bio-oil / water is 1:1) under mechanical stirring, stir and extract at room temperature for half an hour, transfer to 500 mL In the liquid funnel, 327.14 g of water-soluble phase (upper layer) and 72.90 g of oil-soluble phase (lower layer) were obtained. See Table 2 for other indicators of oil-soluble phase and water-soluble phase.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Calorific value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com