A diaphragm with multi-level functional module coupling complementation and preparation method thereof

A technology of functional modules and diaphragms, applied in the direction of separators/films/diaphragms/spacers, structural parts, electrical components, etc., can solve the problems of cumbersome preparation process, unmentioned electrochemical performance of coated diaphragms, etc. Side reactions, the effect of improving the interface between the separator and the electrode, and improving the stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

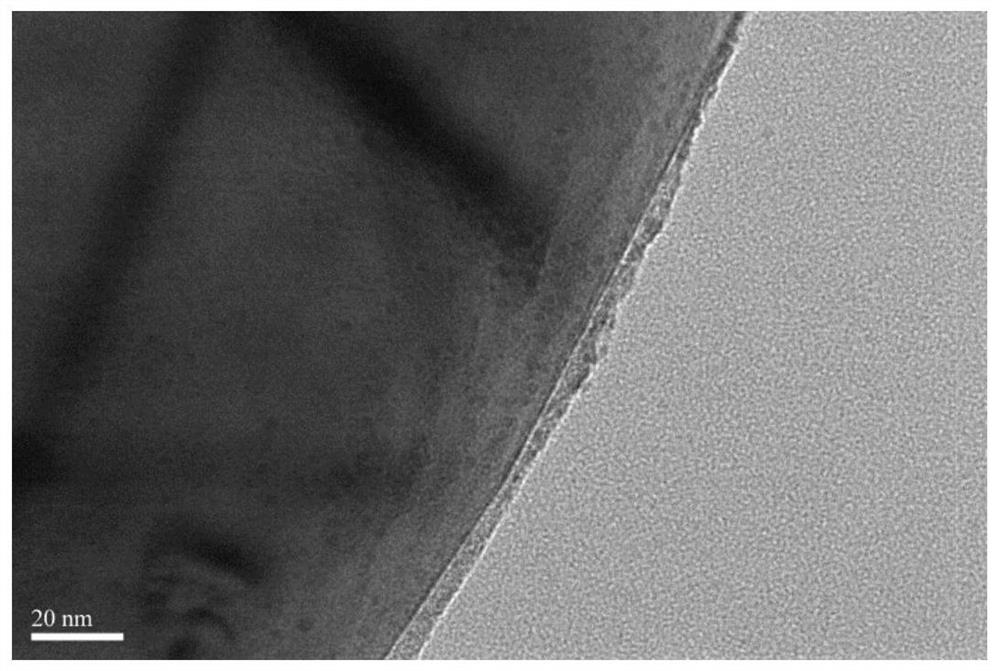

Image

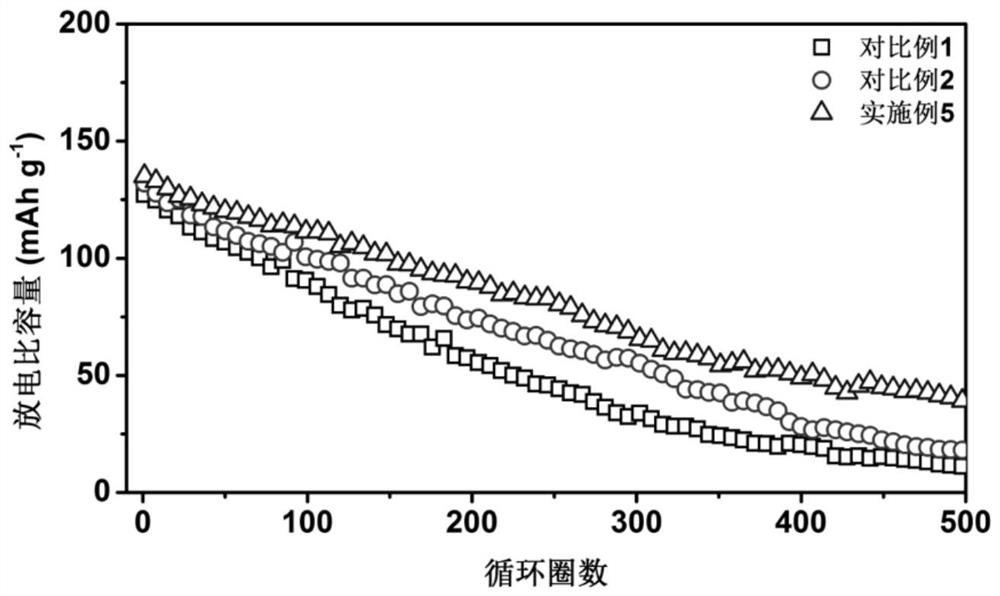

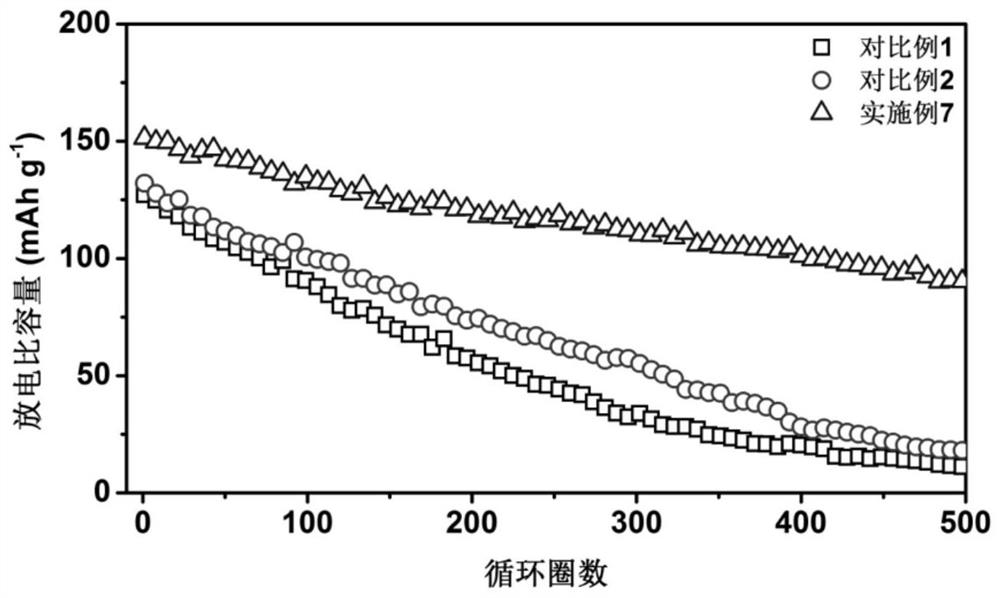

Examples

Embodiment 1

[0043] In this embodiment, a diaphragm with multi-level functional module coupling and complementarity is prepared, and the preparation steps include:

[0044] 15.00 g of tetraethyl orthosilicate (TEOS) and 135.00 g of ethyl acetate were stirred uniformly at room temperature to prepare a 10 wt % TEOS solution as a functional coating solution. Aluminum oxide (Al 2 o 3 ) ceramic coating to coat a polyethylene diaphragm (thickness: 24 μm; base film thickness: 16 μm; double-sided coating), soak it in the above-mentioned functional coating solution for 0.5 h; take out the diaphragm, wait for the ethyl acetate to volatilize naturally, Place the diaphragm in an acidic atmosphere of hydrochloric acid (HCl) and treat it at 30°C for 24 hours; soak and wash the diaphragm with deionized water for 0.5 hours twice, and then soak and wash the diaphragm with absolute ethanol for 0.5 hours; after the diaphragm is surface-dried It was subjected to vacuum treatment at 60°C for 12 hours, and a ...

Embodiment 2

[0047] In this embodiment, a diaphragm with multi-level functional module coupling and complementarity is prepared, and the preparation steps include:

[0048] 15.00 g of tetraethyl orthosilicate (TEOS) and 135.00 g of ethyl acetate were stirred uniformly at room temperature to prepare a 10 wt % TEOS solution as a functional coating solution. Aluminum oxide (Al 2 o 3 ) ceramic coating to coat a polyethylene diaphragm (thickness: 24 μm; base film thickness: 16 μm; double-sided coating), soak it in the above-mentioned functional coating solution for 0.5 h; take out the diaphragm, wait for the ethyl acetate to volatilize naturally, Expose the diaphragm to ammonia gas (NH 3 ) in an alkaline atmosphere at 30°C for 24h; soak and wash the diaphragm with deionized water twice for 0.5h, and then dip and wash the diaphragm with absolute ethanol for 0.5h; After 12 hours of treatment, a membrane with multi-level functional module coupling and complementarity was prepared.

[0049] The...

Embodiment 3

[0051] In this embodiment, a diaphragm with multi-level functional module coupling and complementarity is prepared, and the preparation steps include:

[0052] 15.00 g of tetraethyl orthosilicate (TEOS) and 135.00 g of ethyl acetate were stirred uniformly at room temperature to prepare a 10 wt % TEOS solution as a functional coating solution. Aluminum oxide (Al 2 o 3 ) ceramic coating to coat a polyethylene diaphragm (thickness: 24 μm; base film thickness: 16 μm; double-sided coating), soak it in the above-mentioned functional coating solution for 0.5 h; take out the diaphragm, wait for the ethyl acetate to volatilize naturally, Place the diaphragm at 60°C for 24 hours; soak and wash the diaphragm with deionized water for 0.5 hours twice, and then soak and wash the diaphragm with absolute ethanol for 0.5 hours; after the diaphragm is surface-dried, vacuum-treat it at 60°C for 12 hours , to prepare a complementary membrane with multi-level functional module coupling.

[0053...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com