Method for preparing bio-oil through biomass pyrolysis

A biomass pyrolysis and bio-oil technology, which is applied in the preparation of liquid hydrocarbon mixtures and the petroleum industry, can solve the problems of high acidity of bio-oil, reduce side reactions, improve the quality of bio-oil, and the method is simple and effective

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

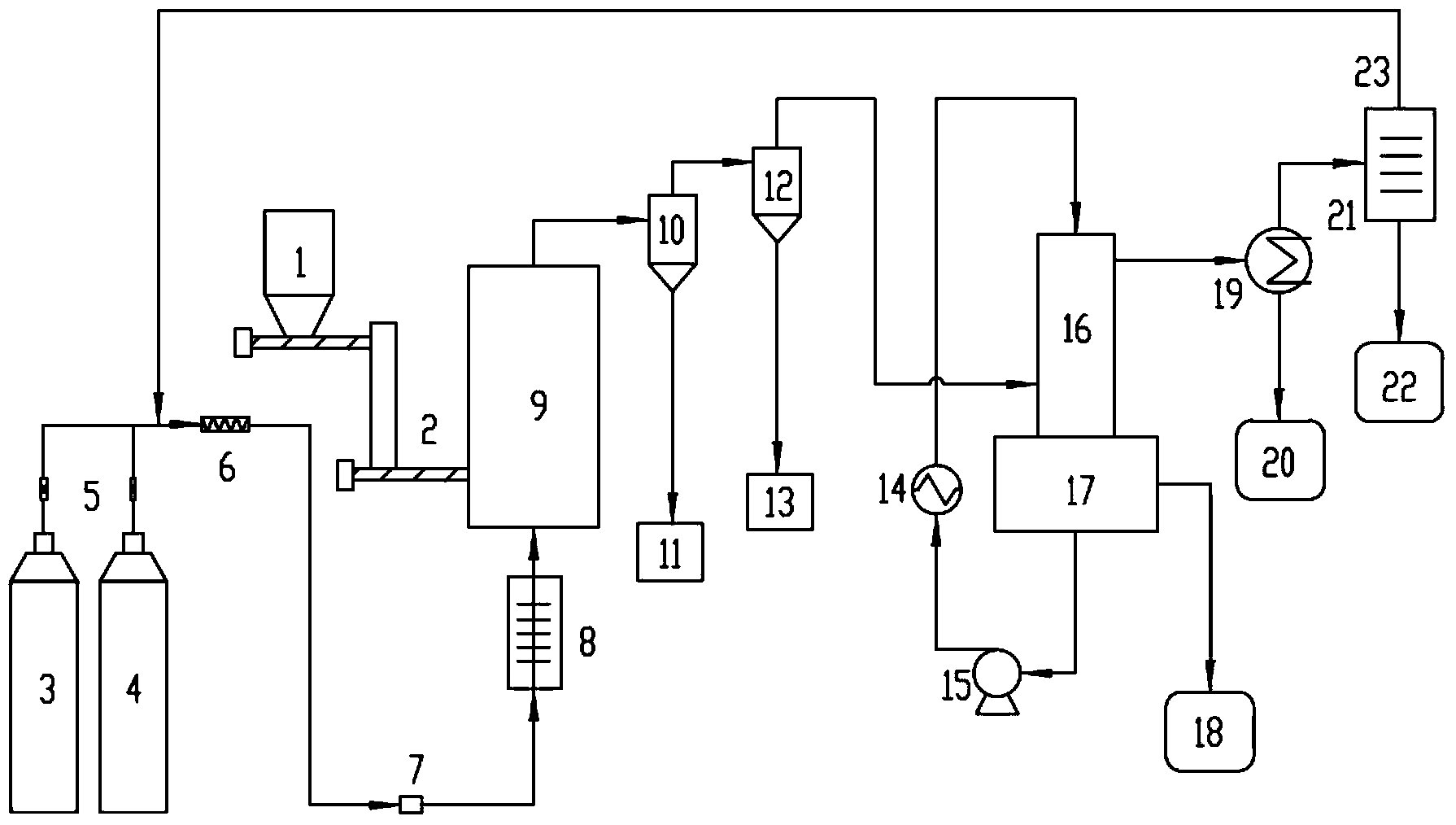

Method used

Image

Examples

Embodiment 1

[0027] The ammonia in the alkaline gas cylinder 3 and the nitrogen in the nitrogen cylinder 4 pass through the flowmeter 5 and enter the gas mixer 6 in a ratio of 1:9 to form a mixed alkaline carrier gas, which passes through the mass flowmeter 7 and then passes into the preheater 8 is preheated, and then enters the pyrolysis reactor 9 so that the reactor forms an alkaline gas atmosphere. Take 1kg of Chinese fir (0.5-3.2mm) and place it in the feeding bin 1, and send it into the pyrolysis reactor 9 by the automatic feeding device 2 to carry out the pyrolysis reaction. The residence time is 1.2s, and the reaction temperature is about 500°C. The pyrolysis steam passes through two cyclone separators 10 and 12, and the solid carbon is separated and collected in the biochar collection tanks 11 and 13. The pyrolysis steam enters the quenching tower 16, and the primary bio-oil obtained by spray cooling is temporarily stored at the bottom of the tower. Storage tank 17, then most of th...

Embodiment 2

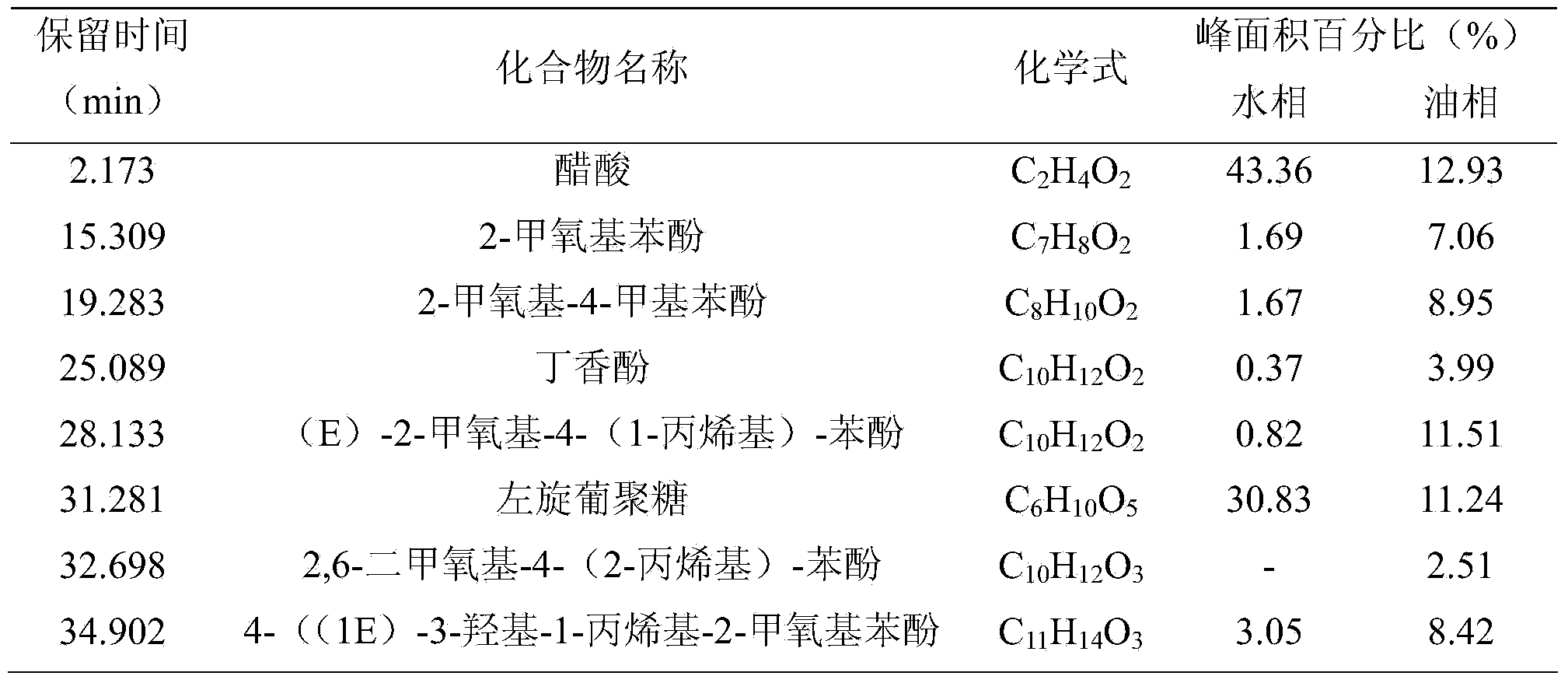

[0033] Similar to Example 1, using Chinese fir (0.5-3.2mm) as raw material, mix ammonia and nitrogen in a ratio of 3:7 to form a mixed alkaline carrier gas for reaction, the residence time is 0.5s, and the reaction temperature is about 550°C . The bio-oil yield rate is 42.63%, and the obtained primary bio-oil accounts for 65%-80% of the bio-oil yield, the water phase part of the primary bio-oil accounts for about 35% of the primary bio-oil, and the water content is 40.05wt%. The pH value is 9.64; the oil phase accounts for about 65%, the water content is 15.80%, and the calorific value is 22.780MJ / kg. The GC-MS analysis results of the primary bio-oil are shown in Table 2.

[0034] Table 2 GC-MS analysis of primary bio-oil

[0035]

Embodiment 3

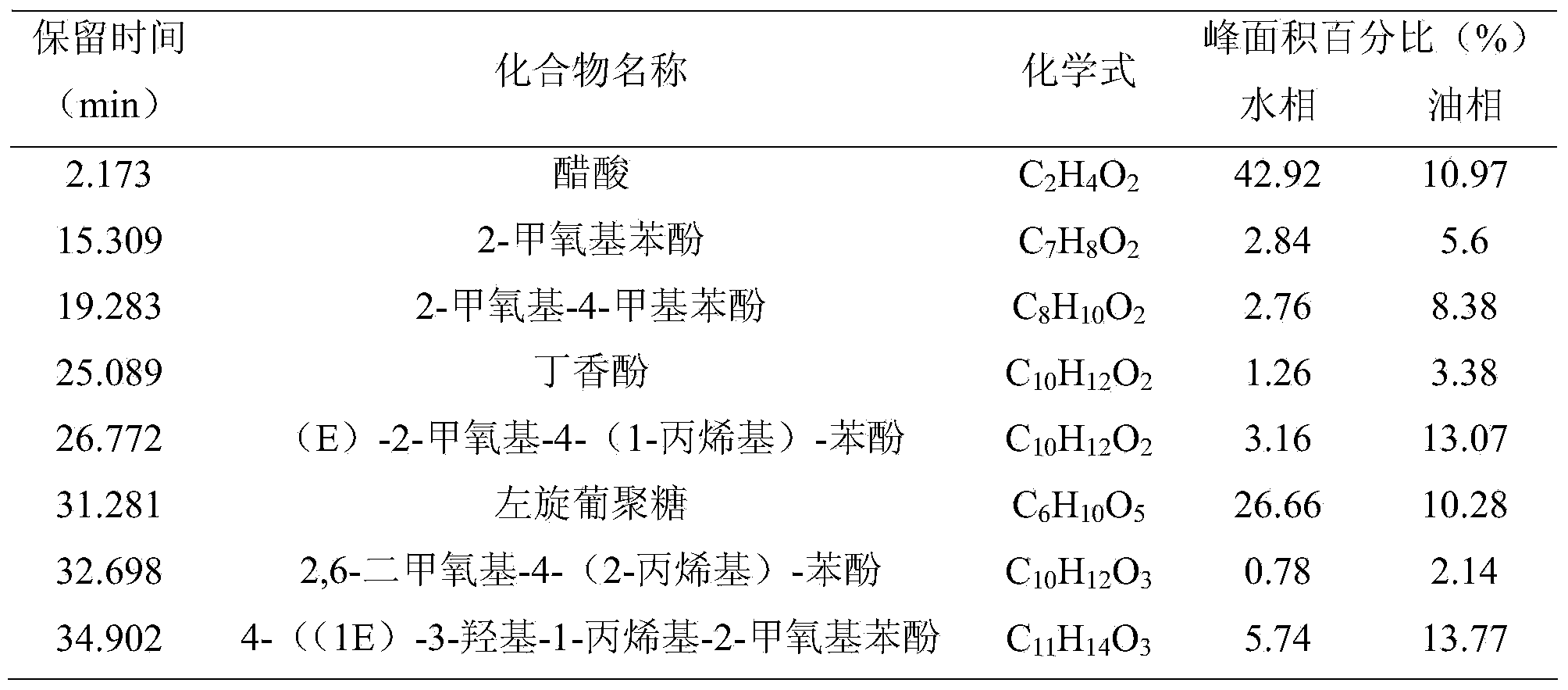

[0037] Similar to Example 1, Chinese fir (0.5-3.2mm) was used as raw material, ammonia and nitrogen were mixed in a ratio of 1:9 to form a mixed alkaline carrier gas for reaction, the residence time was 3s, and the reaction temperature was about 400°C. The bio-oil yield rate is 45.19%, and the obtained primary bio-oil accounts for 65%-80% of the bio-oil yield, the water phase part of the primary bio-oil accounts for about 45% of the primary bio-oil, and the water content is 48.12wt%. The pH value is 10.68; the oil phase accounts for about 55%, the water content is 20.27%, and the calorific value is 20.610MJ / kg. The GC-MS analysis results of the primary bio-oil are shown in Table 3.

[0038] Table 3 GC-MS analysis of primary bio-oil

[0039]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com