Method and device for producing fuel using waste plastics

A plastic and waste technology, which is applied in the petroleum industry, the preparation of liquid hydrocarbon mixtures, etc., can solve the problems of affecting safety production, low oil production rate, poor heat preservation, etc., achieve high temperature resistance and service life, and increase oil production rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

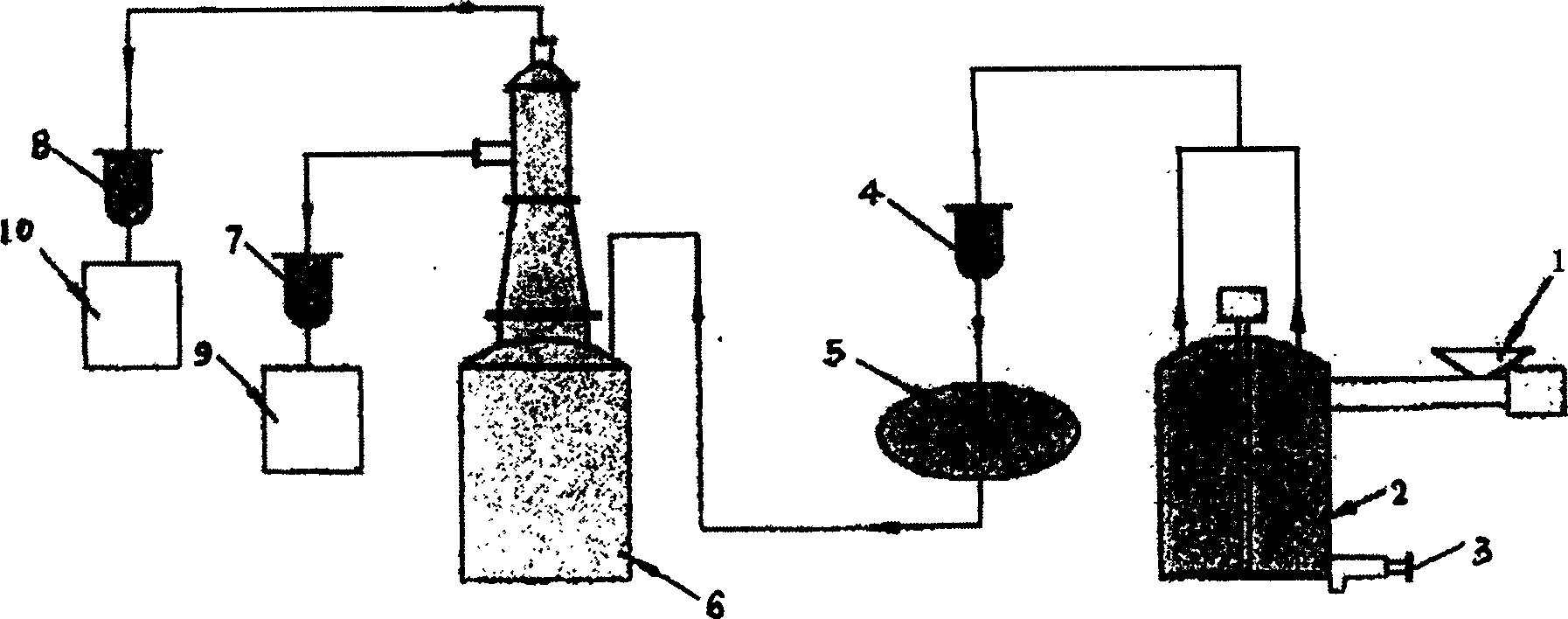

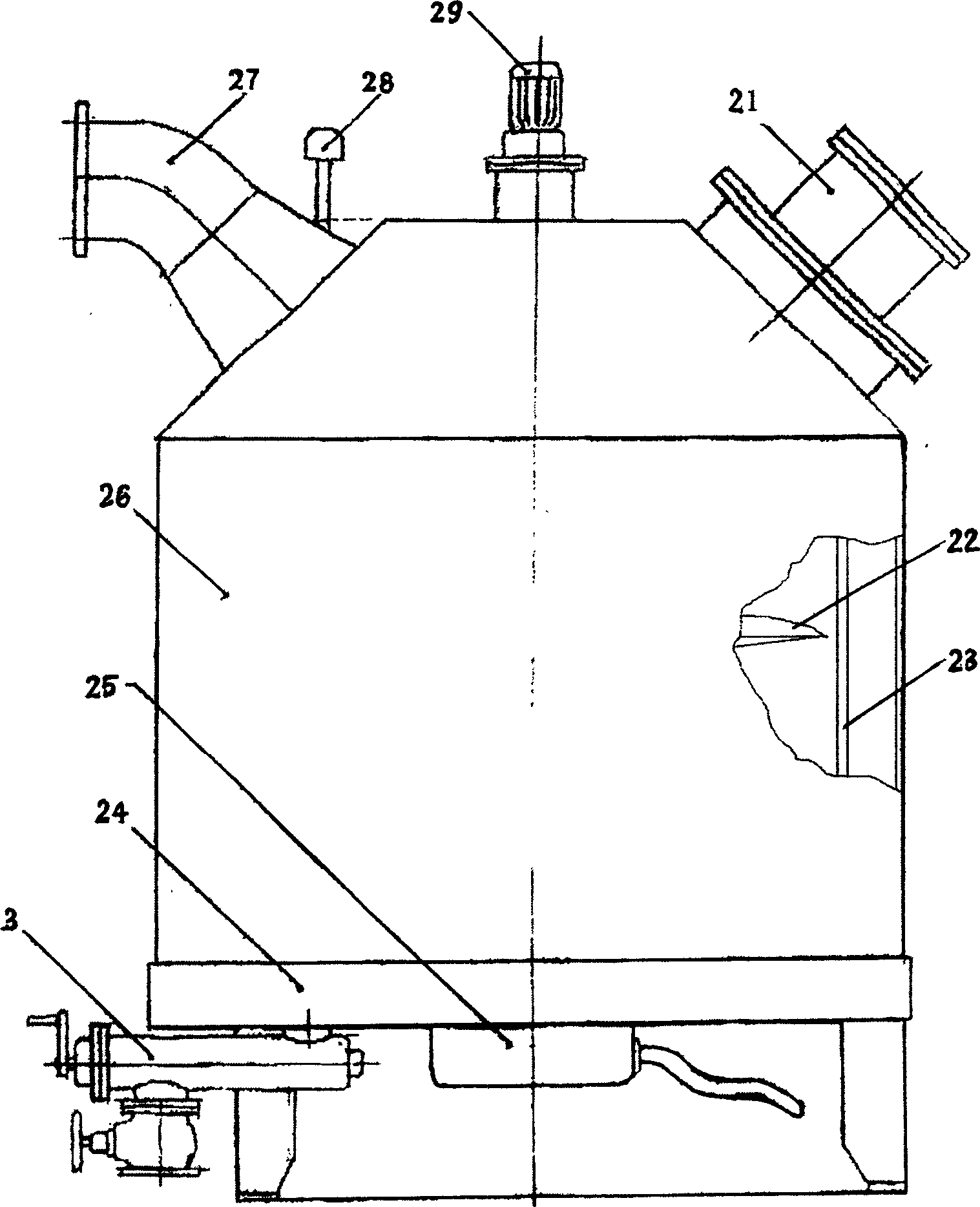

[0037] The present invention includes two parts: the method invention and the device invention, wherein the method part mainly refers to the technological process of converting raw materials into fuels; the device refers to the equipment required for the production method.

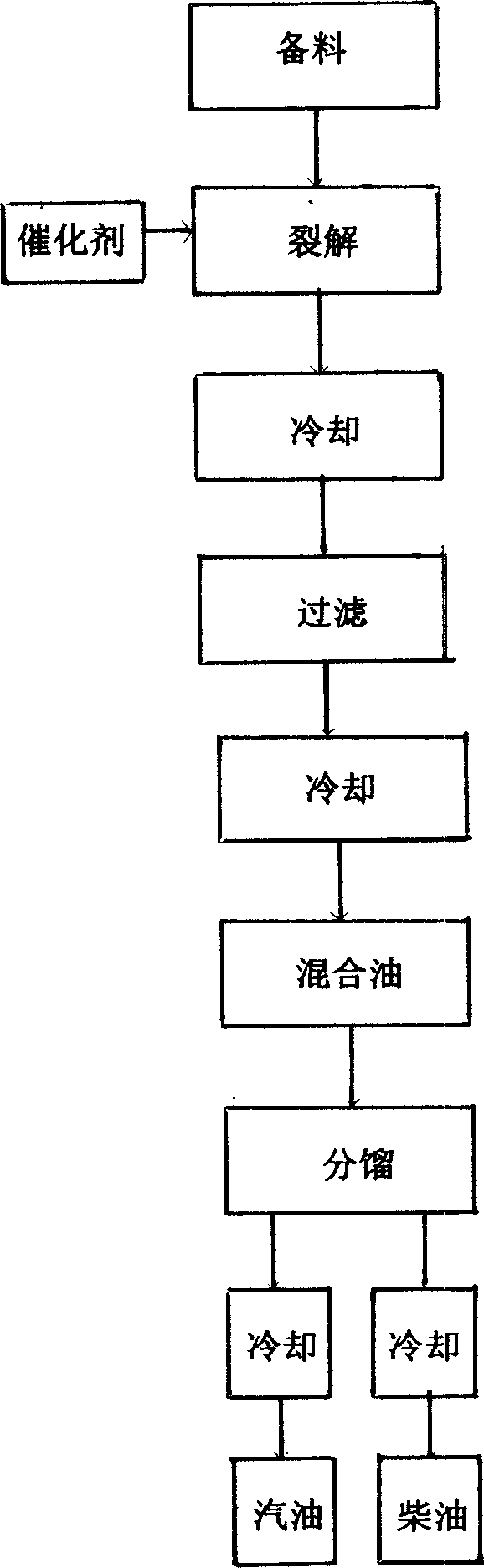

[0038] process flow

[0039] Dry the waste plastic, cut it into small pieces with a plastic cutter if necessary, put the waste plastic and catalyst into the cracking furnace from the feeder, set a vertical shaft stirrer in the furnace, and stir the raw materials intermittently, and use a medium frequency induction heater Heating the cracking furnace, under the agitation of the stirrer, the raw materials and the catalyst are mixed and heated evenly, and the oil vapor generated by the cracking is carried out catalytic cracking, isomerization and aromatization reactions through the catalytic reaction tank, and the oil vapor output from the catalytic tank enters the condensation The gas-liquid mixture is purif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com