Perfume essential oil for tobacco and preparation method and application thereof

A technology for tobacco spices and essential oils, applied in the fields of application, essential oils/flavors, tobacco, etc., can solve the problems of slow degradation of waste, breeding and spreading of diseases and insect pests, blockage of field traffic, etc., achieve rapid oil production rate, and the preparation method is environmentally friendly and The effect of high oil yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The fresh stem leaves of ginger in the mature stage are picked to remove yellow leaves and impurities, washed with water, drained of surface water, freeze-dried, and crushed into 20 meshes. Take 1500 g of stem leaf powder and put it into an extraction device, place it in an extraction kettle, and put it in a 5L Extraction in a supercritical extraction device. CO 2 The flow rate is 30 kg / h; the extraction pressure is 25 MPa; the extraction temperature is 40 °C; the pressure of the first-stage desorption tank is 10 MPa and the temperature is 54 °C; the pressure of the second-stage desorption tank is 8 MPa and the temperature is 54 °C; the extraction time is 100 min. The oil yield was 2.63%.

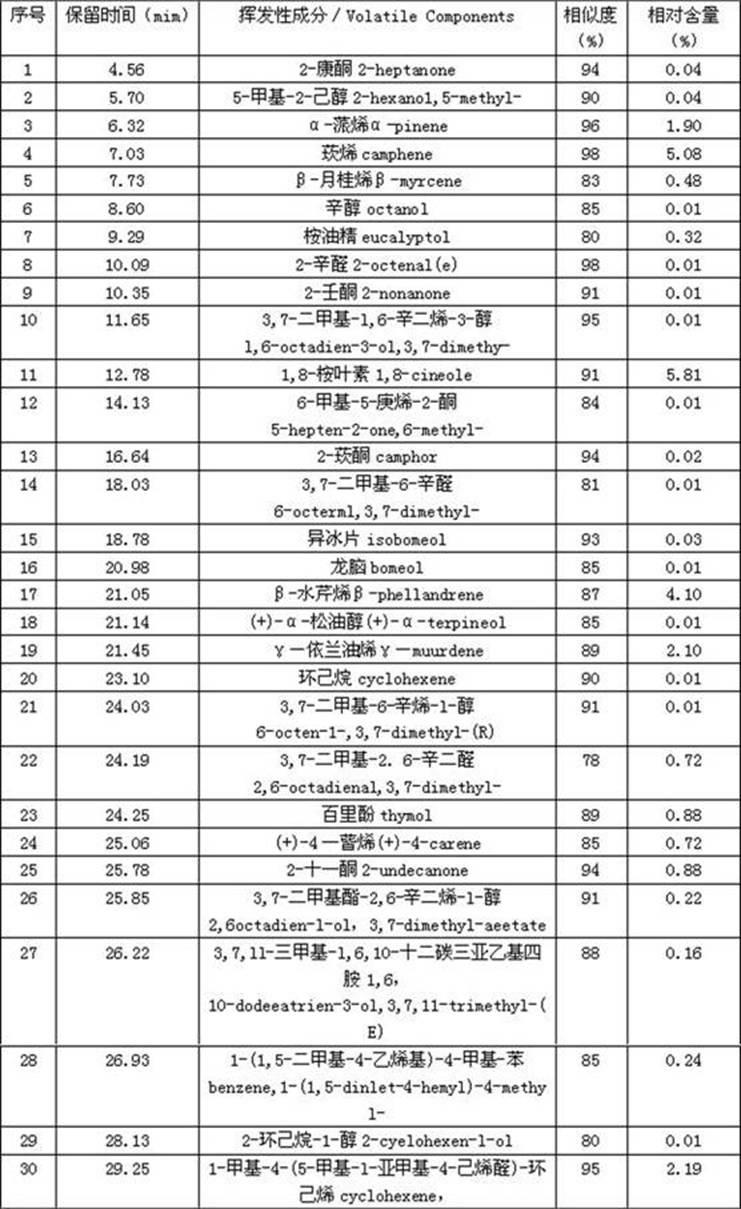

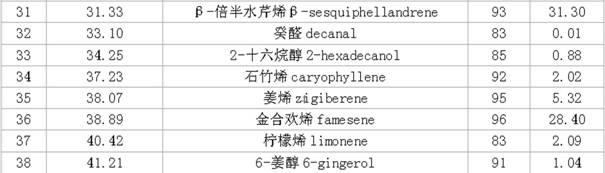

[0020] The obtained essential oils were analyzed for their components, as shown in Table 1.

[0021] Table 1

[0022]

[0023]

[0024] Effect:

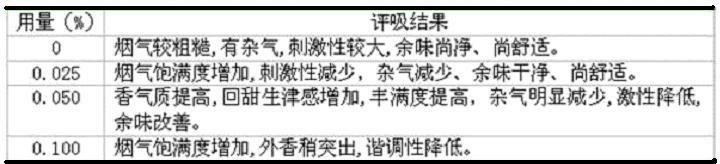

[0025] The essential oil extracted from Example 1 is diluted to 0.4% with absolute ethanol according to the ratio of 0%, 0.025...

Embodiment 2

[0030] The fresh stalk leaves of ginger in the late stage of maturity, remove the yellow leaves and impurities, wash with water, drain the surface water, freeze-dry and crush into 40 meshes, take 1500 g of stalk leaf powder and put it into the extraction device, put it in the extraction kettle, and put it in a 5L Extraction in a supercritical extraction device. CO 2 The flow rate is 25 kg / h; the extraction pressure is 20 MPa; the extraction temperature is 35 °C; the pressure of the first-stage desorption tank is 11 MPa and the temperature is 40 °C; the pressure of the second-stage desorption tank is 6 MPa and the temperature is 40 °C; the extraction time is 80 min. The oil yield was 2.41%.

Embodiment 3

[0032] The fresh stalk leaves of ginger in the late stage of maturity, remove the yellow leaves and impurities, wash with water, drain the surface water, freeze-dry and crush into 30 meshes, take 1500 g of stalk leaf powder and put it into the extraction device, put it in the extraction kettle, and put it in a 5L Extraction in a supercritical extraction device. CO 2 The flow rate is 20 kg / h; the extraction pressure is 25 MPa; the extraction temperature is 40 °C; the pressure of the first-stage desorption tank is 12 MPa and the temperature is 45 °C; the pressure of the second-stage desorption tank is 8 MPa and the temperature is 45 °C; the extraction time is 120 min. The oil yield was 2.24%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com