Covalent triazine framework material with rich defects, and preparation method and application thereof

A technology with covalent triazine skeleton and defects, applied in chemical instruments and methods, other chemical processes, water/sludge/sewage treatment, etc. The effect of high efficiency, low cost and easy preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

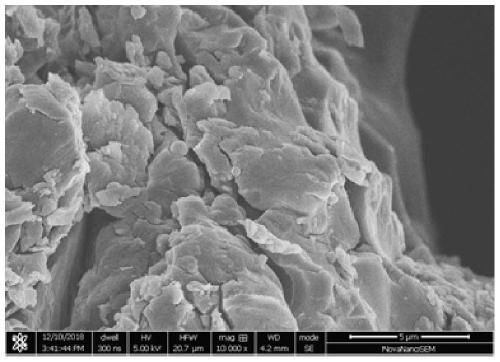

Image

Examples

Embodiment 1

[0029] In this example, the specific steps for preparing a triazine covalent framework material with abundant defects are as follows:

[0030] (1) Add 2mmol of 1,4-terephthalonitrile and 2mmol of 4,4-biphenyldinitrile into the quartz tube in turn, add the rotor, and stir evenly with a magnetic stirrer.

[0031] (2) In an ice-water bath at 0° C., under the protection of nitrogen atmosphere, slowly add 2.5 mL of trifluoromethanesulfonic acid into the quartz tube and keep stirring for 1.5 h to obtain a uniform viscous solution.

[0032] (3) The quartz tube was then transferred to an electric thermostat blast drying oven, and kept at 100° C. for 20 min to obtain a transparent solid substance.

[0033] (4) After grinding the obtained solid with a mortar, it was washed with ethanol and water three times in sequence.

[0034] (5) Dry in an oven at 60°C for 24 hours to obtain a light yellow powder, which is a covalent triazine skeleton with abundant defects.

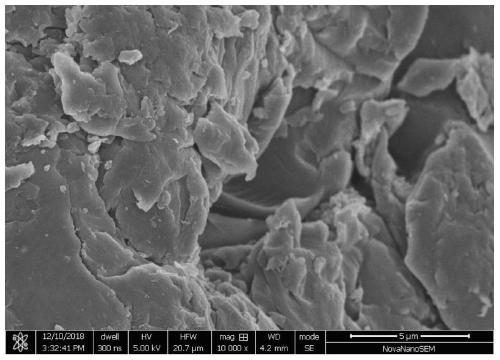

Embodiment 2

[0036] In this example, the specific steps for preparing a triazine covalent framework material with abundant defects are as follows:

[0037] (1) Add 1mmol of 1,4-terephthalonitrile and 1mmol of 4,4-biphenyldinitrile into the quartz tube in turn, add the rotor, and stir evenly with a magnetic stirrer.

[0038] (2) In an ice-water bath at 0° C., under the protection of nitrogen atmosphere, slowly add 1.25 mL of trifluoromethanesulfonic acid into the quartz tube and keep stirring for 1.5 h to obtain a uniform viscous solution.

[0039] (3) The quartz tube was then transferred to an electric thermostat blast drying oven, and kept at 100° C. for 20 min to obtain a transparent solid substance.

[0040] (4) After grinding the obtained solid with a mortar, it was washed with ethanol and water three times in sequence.

[0041] (5) Dry in an oven at 60°C for 24 hours to obtain a light yellow powder, which is a covalent triazine skeleton with abundant defects.

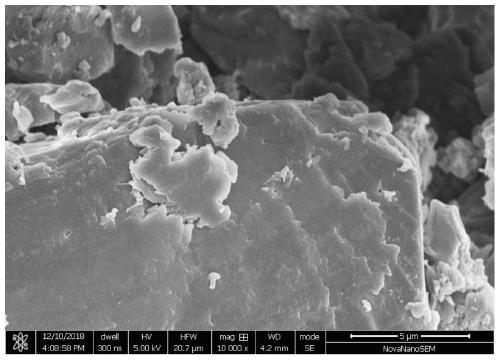

Embodiment 3

[0043] In this example, the specific steps for preparing a triazine covalent framework material with abundant defects are as follows:

[0044] (1) Add 3mmol 1,4-terephthalonitrile and 3mmol 4,4-biphenyldinitrile to the quartz tube in turn, add the rotor, and stir evenly with a magnetic stirrer.

[0045] (2) In an ice-water bath at 0° C., under the protection of nitrogen atmosphere, slowly add 3.75 mL of trifluoromethanesulfonic acid into the quartz tube and keep stirring for 1.5 h to obtain a uniform viscous solution.

[0046] (3) The quartz tube was then transferred to an electric thermostat blast drying oven, and kept at 100° C. for 20 min to obtain a transparent solid substance.

[0047] (4) After grinding the obtained solid with a mortar, it was washed with ethanol and water three times in sequence.

[0048] (5) Dry in an oven at 60°C for 24 hours to obtain a light yellow powder, which is a covalent triazine skeleton with abundant defects.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com