Functional diaphragm based on mesoporous alumina with high specific surface area as well as preparation method and application of functional diaphragm

A technology of mesoporous alumina and high specific surface area, which can be used in non-aqueous electrolyte batteries, structural parts, electrical components, etc., can solve the problem of being unable to suppress the lithium polysulfide shuttle effect, achieve the suppression of polysulfide shuttle effect, and low price , easy and convenient preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] S / CNT (S: CNT = 8: 2) composite materials, conductive agents Super-p and PVDF were mixed with a mass ratio of 7:2:1, and then a certain volume of NMP was added as a solvent to prepare a bindable slurry, which was coated on the aluminum foil after wiping with alcohol, and the surface load of S was controlled at 1.0mg / cm 2 Around. The aluminum foil coated with the paste is removed after vacuum drying in a 60 °C oven for 12 h, and it is cut into a 14 mm diameter disc with a tablet press as a positive plate for the button battery.

[0036]Assembly of the button battery: Battery case type: CR2032, PP separator model: Celgard2400, negative electrode: lithium sheet (purity ≥99.5%), electrolyte composition: 1M LiTFSI, DOL / DME (1:1, v / v), 1% LiNO 3 (wt%), electrolyte dosage: 30 to 40 μL, glove box: Ar gas (O 2 <0.01ppm,H 2 O<0.01ppm)。

Embodiment 2

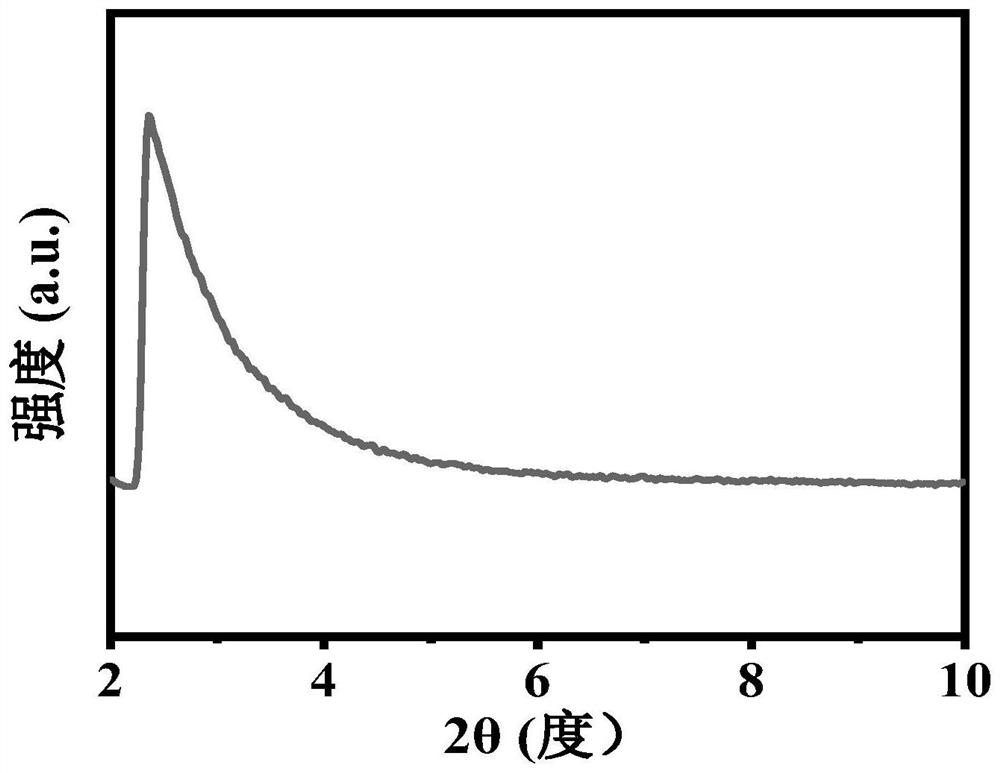

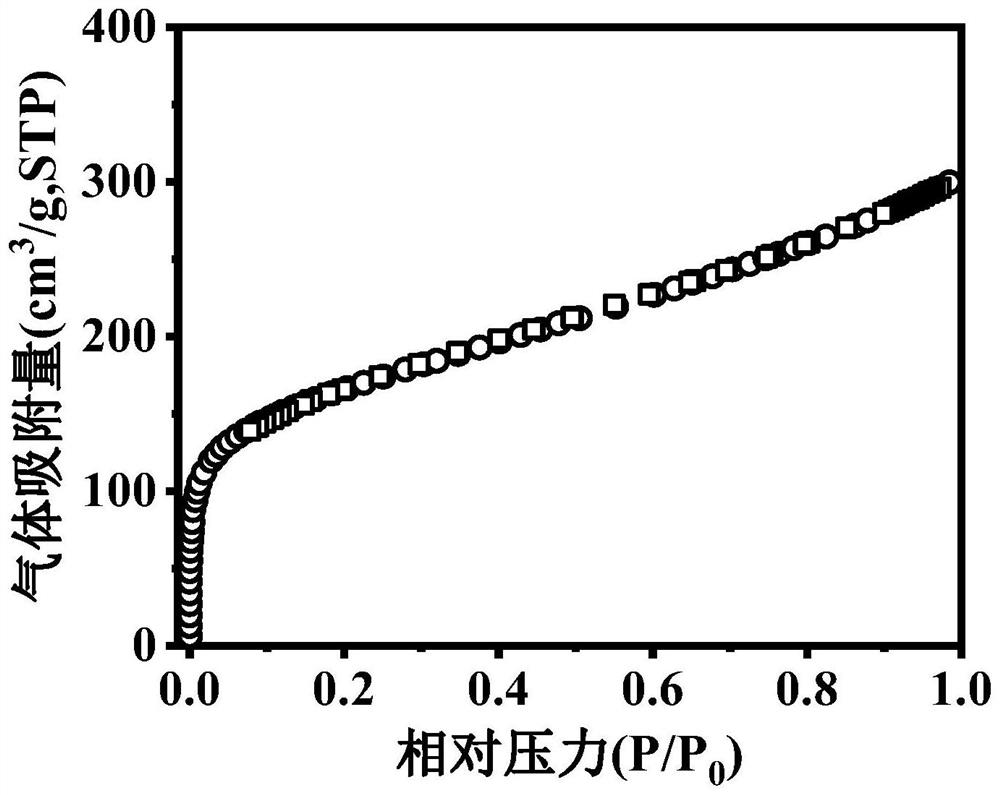

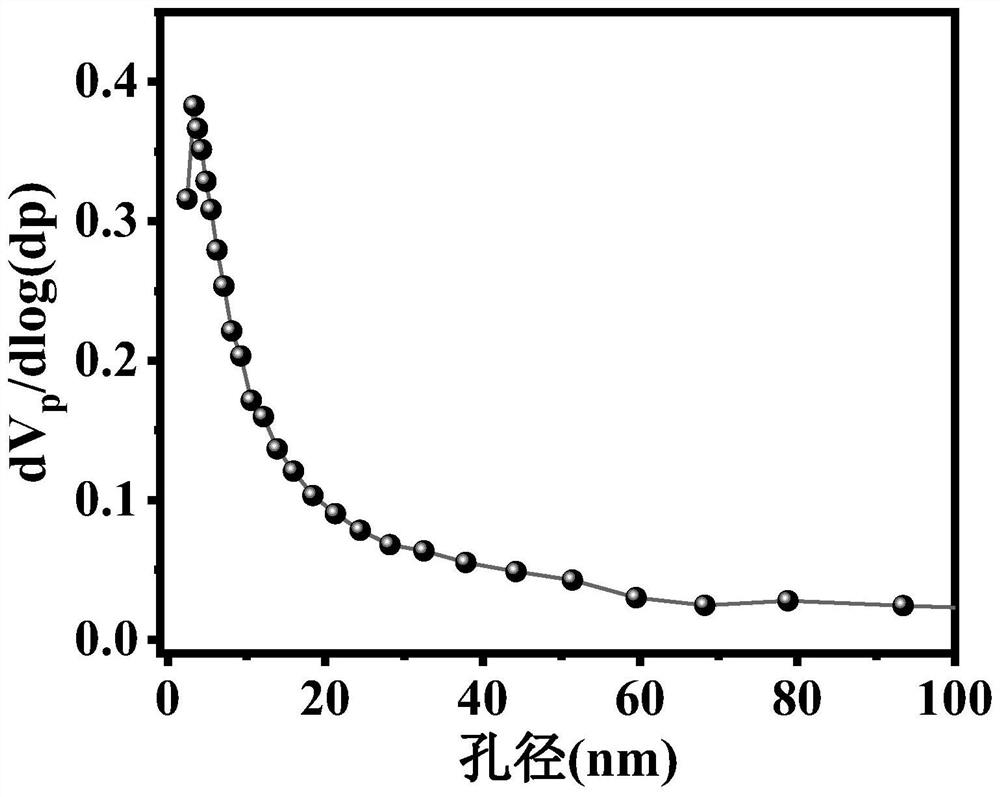

[0038] Synthesis of 1.MA: 5.1 g stearic acid dissolved in n-propanol. Add 3.1 ml of water and stir for about 30 min. Add 13.7 g of sec-butanol aluminum, stir for another 20 min, and then heat at 100 °C for 50 hours, the resulting product is filtered, washed with 99% absolute ethanol, and dried at 50 °C for 12 hours. The resulting powder is calcined for 4 hours in a nitrogen atmosphere at 410 °C, and then calcined in an air atmosphere of 420 °C for 4 hours. The resulting final product is a mesoporous alumina (MA) having a high specific surface area of the present invention.

[0039] 2. Sonically dissolve MA and G plus absolute ethanol, and then use PP diaphragm as the base for pumping filtration, and the diaphragm load is 0.24mg / cm 2 Finally, dry under vacuum for 12 h. The specific steps are as follows: weigh 3 mg MA, 7 mg graphene, add 50 ml of absolute ethanol, sonicate for 1 h, pump filtration with PP diaphragm as the base, and finally, dry under vacuum for 12 h, cut into discs ...

Embodiment 3

[0046] Synthesis of 1.MA: 5.1 g stearic acid dissolved in n-propanol. Add 3.1 ml of water and stir for about 30 min. Add 13.7 g of sec-butanol aluminum, stir for another 20 min, and then heat at 100 °C for 50 hours, the resulting product is filtered, washed with 99% absolute ethanol, and dried at 50 °C for 12 hours. The resulting powder is calcined for 4 hours in a nitrogen atmosphere at 410 °C, and then calcined in an air atmosphere of 420 °C for 4 hours. The resulting final product is a mesoporous alumina (MA) having a high specific surface area of the present invention.

[0047] 2. Sonically dissolve MA and G plus absolute ethanol, and then, with pp diaphragm as the substrate for pumping filtration, the diaphragm load is 0.24mg / cm 2 Finally, dry under vacuum for 12 h. The specific steps are as follows: weigh 2 mg MA, 8 mg graphene, add 50 ml of absolute ethanol, sonicate for 1 h, pump filtration with PP diaphragm as the base, and finally, dry under vacuum for 12 h, cut into dis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com